Preparation device for drum type support

A technology for preparing devices and supports, applied in feeding devices, mechanical equipment, manufacturing tools, etc., can solve the problem of not mass-producing drum-shaped supports, etc., to avoid shape accuracy errors, high rolling accuracy, and uniform blanking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

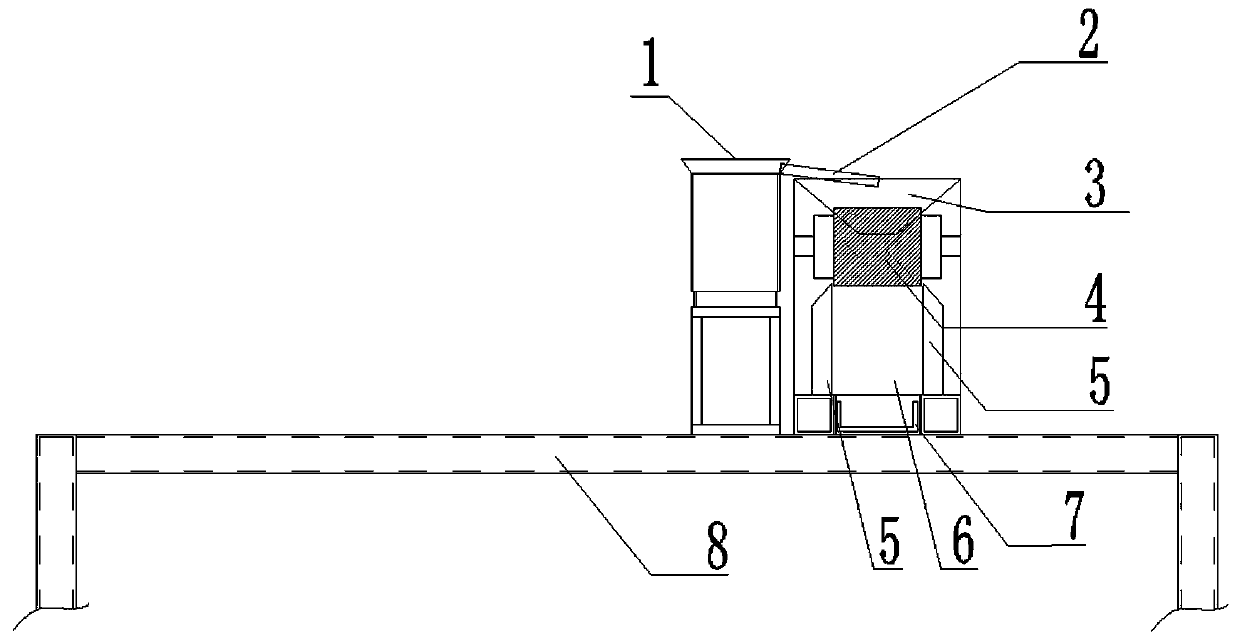

[0032] Such as figure 1 , 3 , shown in 4, a kind of preparation device of drum-shaped support, comprises the feeding arrangement mechanism that is installed on the frame 8, rolling mill and material receiving device 7, wherein the feeding arrangement mechanism adopts the vibrating plate arrangement mechanism, It includes a vibrating plate 1, a feeding trough 2 and a conical blanking mechanism 3. The feeding trough 2 is arranged obliquely. One end is connected to the outlet of the vibrating plate 1, and the other end is connected to the conical blanking mechanism 3. The vibrating plate 1 vibrates the spherical raw material 9. Like steel balls, they are sent into the feeding trough 2 at a uniform speed and orderly, and the spherical raw material 9 enters the conical blanking mechanism 3 along the feeding trough 2, and falls into the rolling mill below the conical blanking mechanism 3 for extrusion. Compression molding, the conical blanking mechanism 3 adopts a funnel;

[0033]...

Embodiment 2

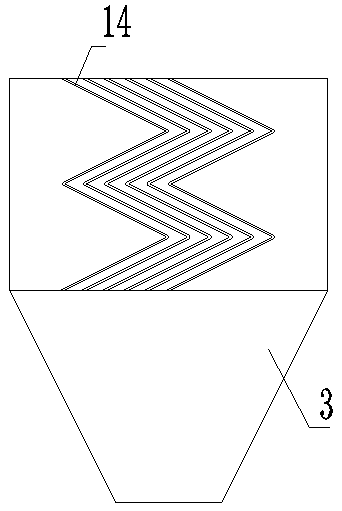

[0040] Compared with Embodiment 1, this embodiment adopts a groove structure and a conical blanking mechanism 3 for the feeding and arranging mechanism, such as figure 2 As shown, the groove 14 in the groove mechanism is connected to the conical blanking mechanism 3, and the feeding speed and flow of the spherical raw material are controlled by the inclination, opening and closing of the groove 14, or the bending of the route. The brush is set to rotate and feed the material, and the rolling mill and the material receiving device 7 are set with the same structure as that of Embodiment 1.

[0041] In the above two embodiments, the material receiving tray and the material retaining device are both made of PVC board.

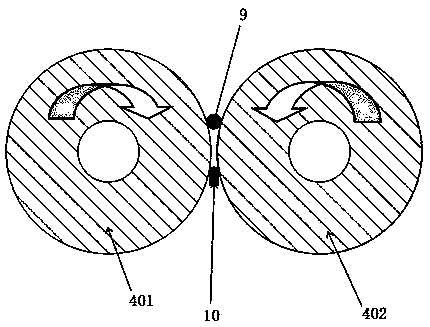

[0042] The shape of the drum support is as Figure 4 As shown, its forming process is as follows image 3 As shown, spherical raw materials 10, such as steel balls, enter the rolling mill through the feeding and arranging mechanism, and are extruded into such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com