Manufacturing method of acrylic rubber

A technology of acrylic rubber and its manufacturing method, which is applied in the field of manufacturing acrylic rubber, can solve problems such as not necessarily sufficient and unable to meet the requirements of tensile strength, and achieve the effects of inhibiting dirt, high tensile strength, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

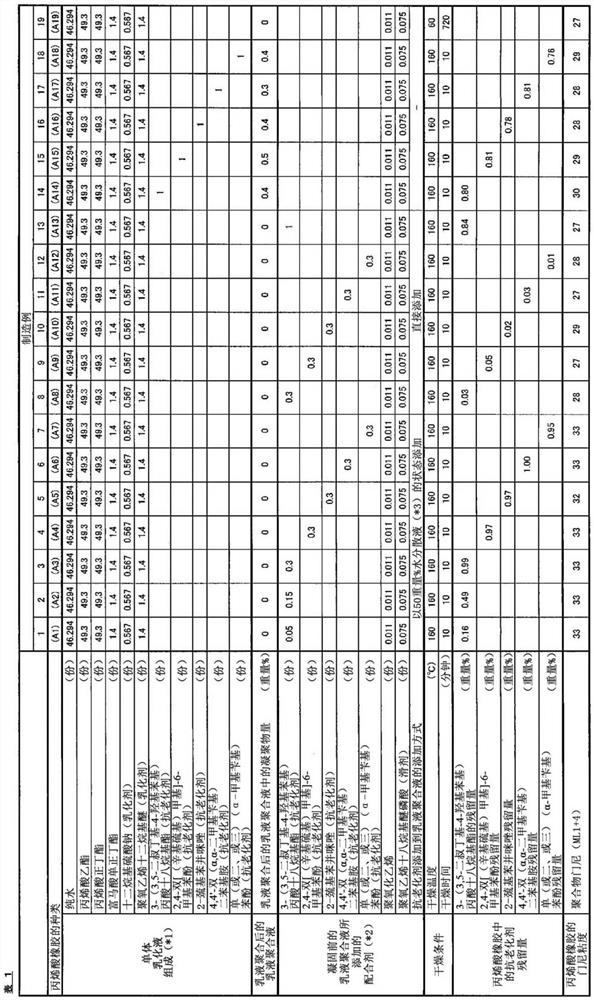

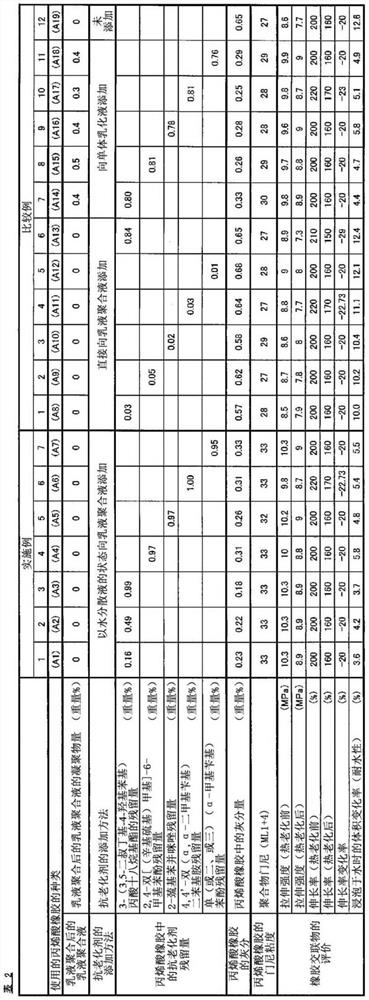

[0150] Hereinafter, the present invention will be described in more detail with reference to Examples and Comparative Examples. In addition, unless otherwise indicated, the "part" in each example is a basis of weight.

[0151] Various physical properties were evaluated by the following methods.

[0152] [Mooney viscosity (ML1+4, 100℃)]

[0153] The Mooney viscosity (polymer Mooney) of acrylic rubber was measured in accordance with JIS K6300.

[0154] [Content of aggregates in emulsion polymerization solution after emulsion polymerization]

[0155] For the emulsion polymerization liquid after the emulsion polymerization, the content ratio of the solid content (the ratio when the whole emulsion polymerization liquid is taken as 1) is measured, and then 100 g of the emulsion polymerization liquid after the emulsion polymerization is accurately weighed, and then a known weight is used. The 200-mesh SUS metal mesh was filtered, and the agglomerate on the metal mesh was washed se...

manufacture example 1

[0173] In a mixing vessel with a homogenizer, 46.294 parts of pure water, 49.3 parts of ethyl acrylate, 49.3 parts of n-butyl acrylate, 1.4 parts of mono-n-butyl fumarate, and 0.567 parts of anionic surfactant were added Sodium lauryl sulfate (trade name "EMAL 2FG", manufactured by Kao Corporation) and 1.4 parts of polyoxyethylene lauryl ether (trade name "EMULGEN 105" as a nonionic surfactant, weight average molecular weight : about 1500, manufactured by Kao Corporation), and stirring was performed to obtain a monomer emulsion.

[0174] Next, 170.853 parts of pure water and 2.97 parts of the monomer emulsion obtained above were put into a polymerization reaction tank equipped with a thermometer and a stirring device, and cooled to a temperature of 12°C under nitrogen flow. Next, 145.29 parts of the monomer emulsion obtained above, 0.00033 parts of ferrous sulfate as a reducing agent, 0.264 parts of sodium ascorbate as a reducing agent, and 7.72 parts of 2.85% by weight persul...

manufacture example 2

[0180] Using the emulsion polymerization liquid obtained in the same manner as in Production Example 1, 3-(3,5-di-tert- The addition amount of the 50% by weight aqueous dispersion of octadecyl butyl-4-hydroxyphenyl)propionate was changed from 0.1 part to 0.3 part (with respect to 100 parts of the monomer added when producing the emulsion polymerization liquid) Except for the total of 0.5 part in terms of the anti-aging agent), the preparation of the mixed solution and the coagulation operation were carried out in the same manner as in Production Example 1, and the water-containing aggregate of the acrylic rubber (A2) was obtained.

[0181] Next, in the same manner as in Production Example 1, the obtained water-containing pellets of acrylic rubber (A2) were washed with water, acid washed, washed with pure water, and dried using a hot air dryer four times to obtain a solid acrylic rubber (A2) . The Mooney viscosity (ML1+4, 100° C.) of the obtained acrylic rubber (A2) was 33, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com