Straw smashing and collecting vehicle and collecting method

A straw crushing and collecting vehicle technology, which is applied to motor vehicles, harvesters, tractor-trailer combinations, etc., can solve the problems of low efficiency of straw collecting and leaving the field, large investment in collecting equipment, and difficulty in popularizing and popularizing, so as to promote the collection of straws. The effect of utilization, high work efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

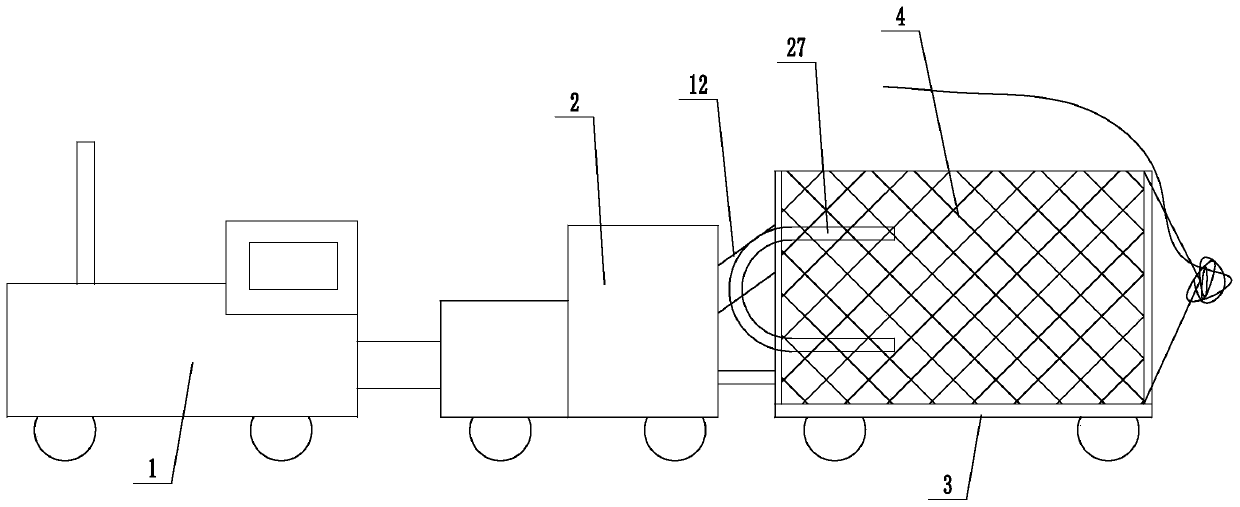

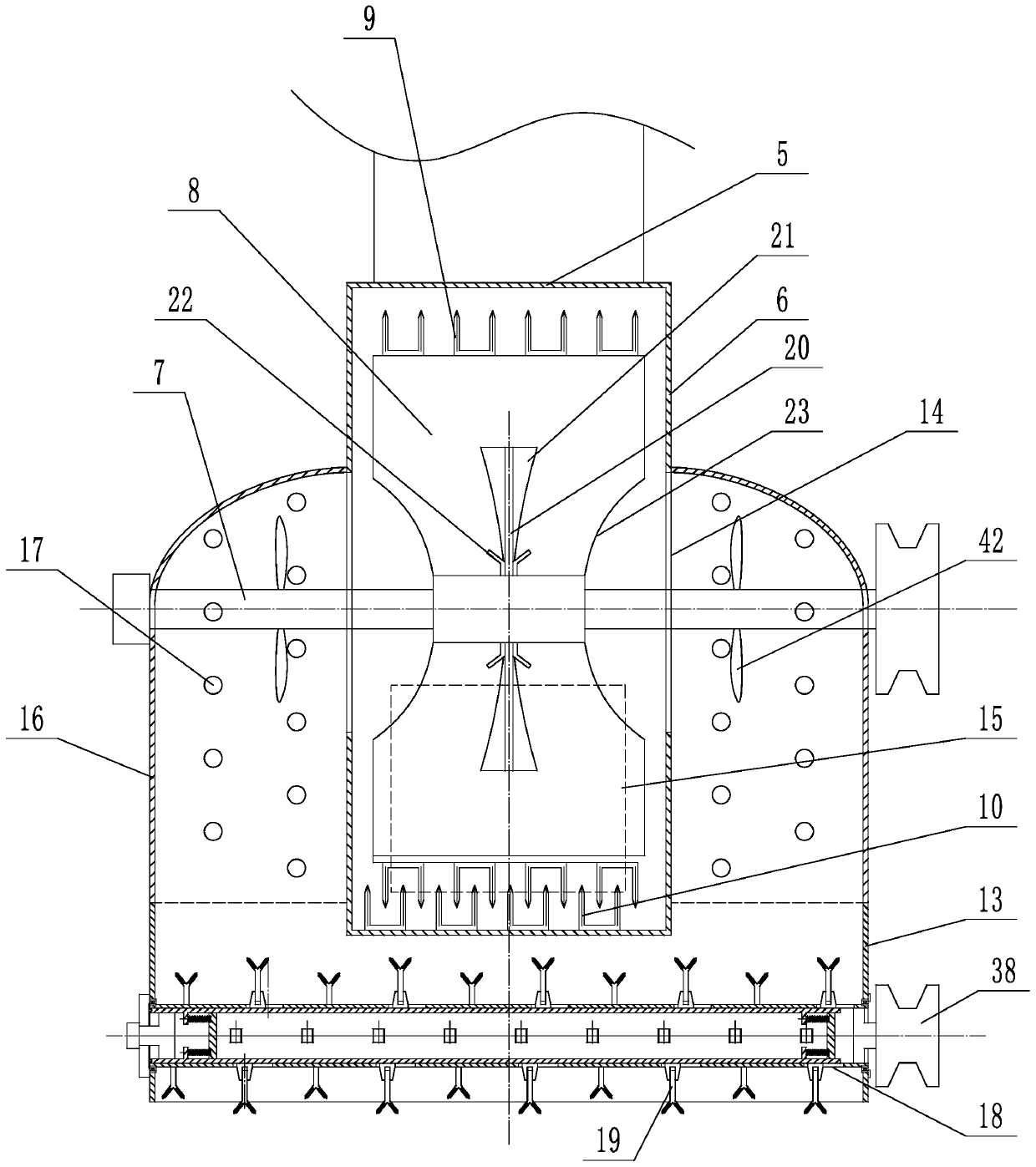

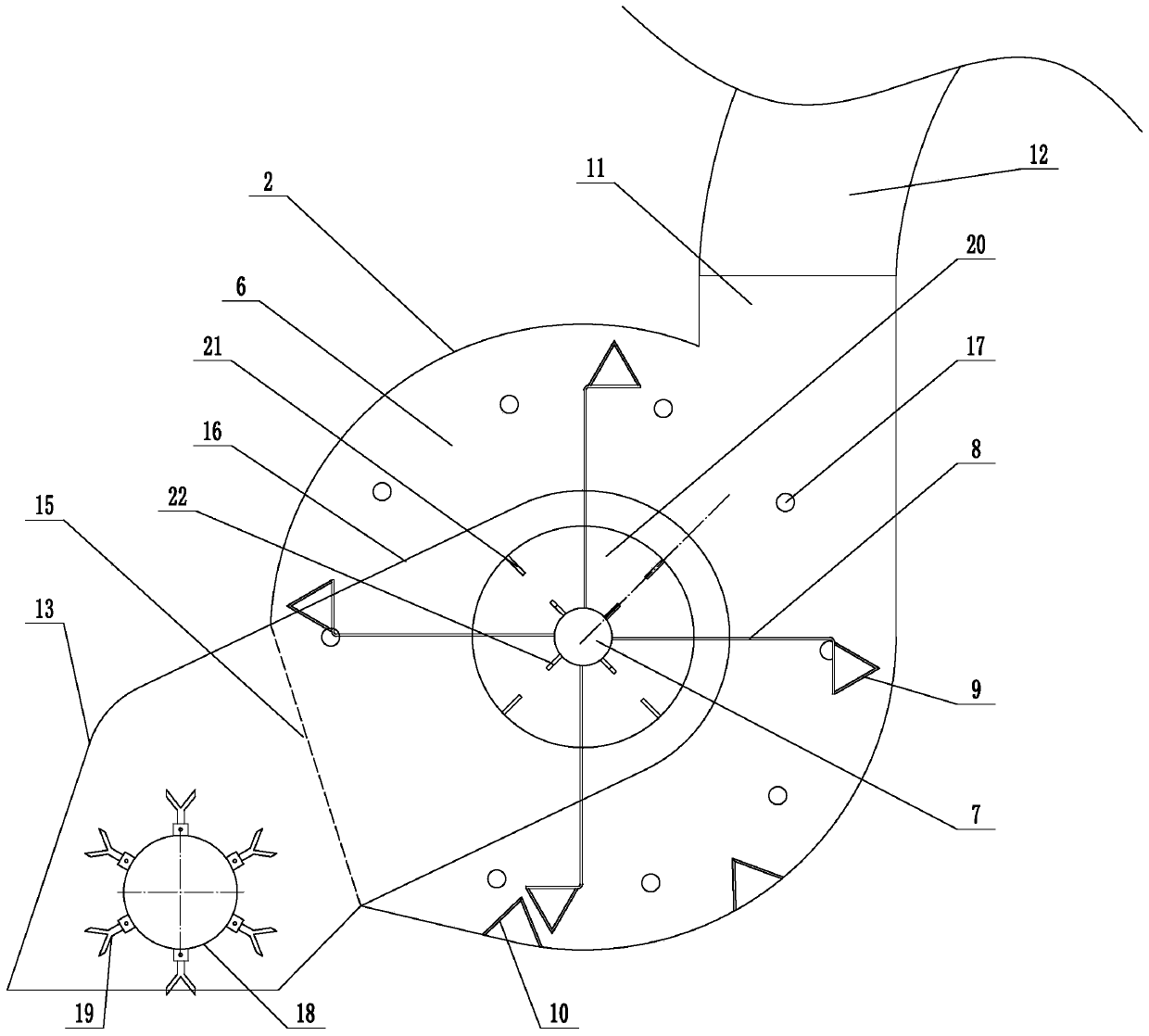

[0023] Embodiment: a kind of stalk crushing and collecting vehicle (see attached figure 1 to attach Figure 5), including the tractor head 1, the cutting and throwing fan 2 and the trailer 3 dragged by the tractor head. The casing 5, the side plates 6 connected to the left and right sides of the arc mechanism, the power shaft 7, some throwing blades 8 evenly distributed on the power shaft, the throwing blades are arranged in the casing, and the edges of the throwing blades are provided with Cutting material moving knife 9, on the casing inner wall and cutting material moving knife are equipped with cutting material fixed knife 10, and cutting material moving knife and cutting material fixed knife are all triangular; Connect the material throwing pipe 12 on the feed opening, and the material throwing pipe is set towards the feeding port of the self-unloading grass net bag, the lower end of the casing is connected to the feeding casing 13, and the side plates are all provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com