Deodorizing device for cloth processing

A cloth and mounting board technology, which is applied in the direction of processing textile material equipment configuration, processing textile material carrier, spraying/spraying textile material processing, etc., can solve the problems of low work efficiency, troublesome operation, difficult collection, etc., to improve work efficiency, The effect of increasing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

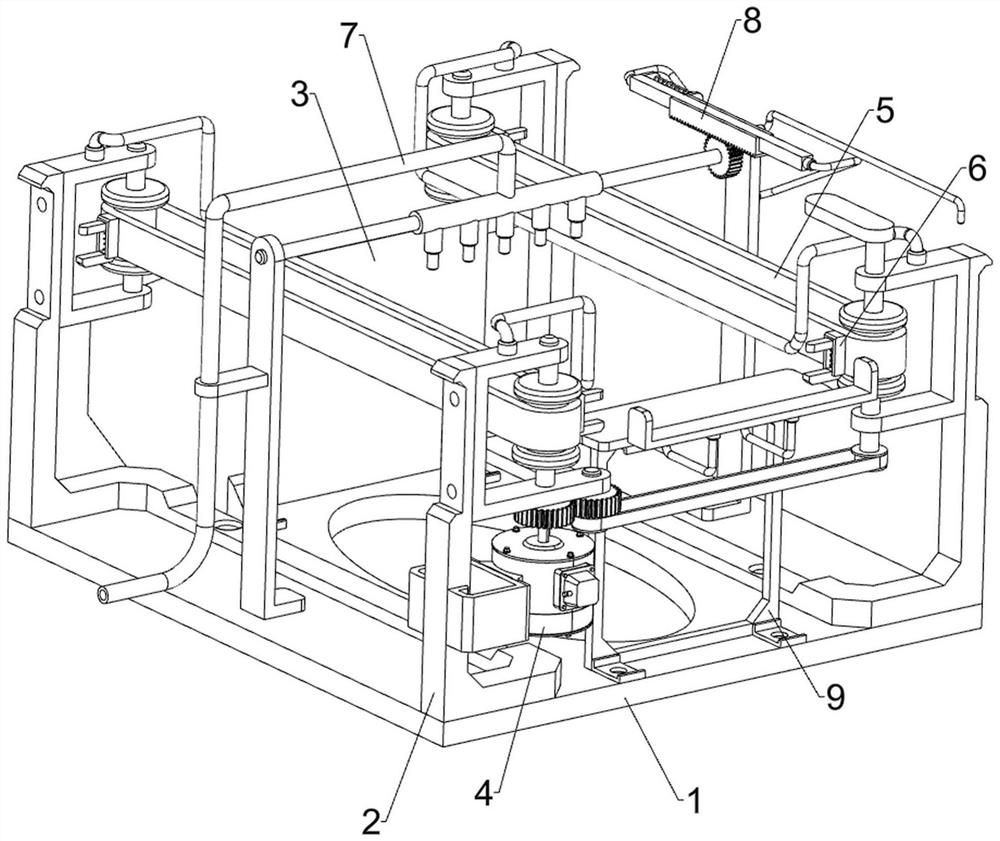

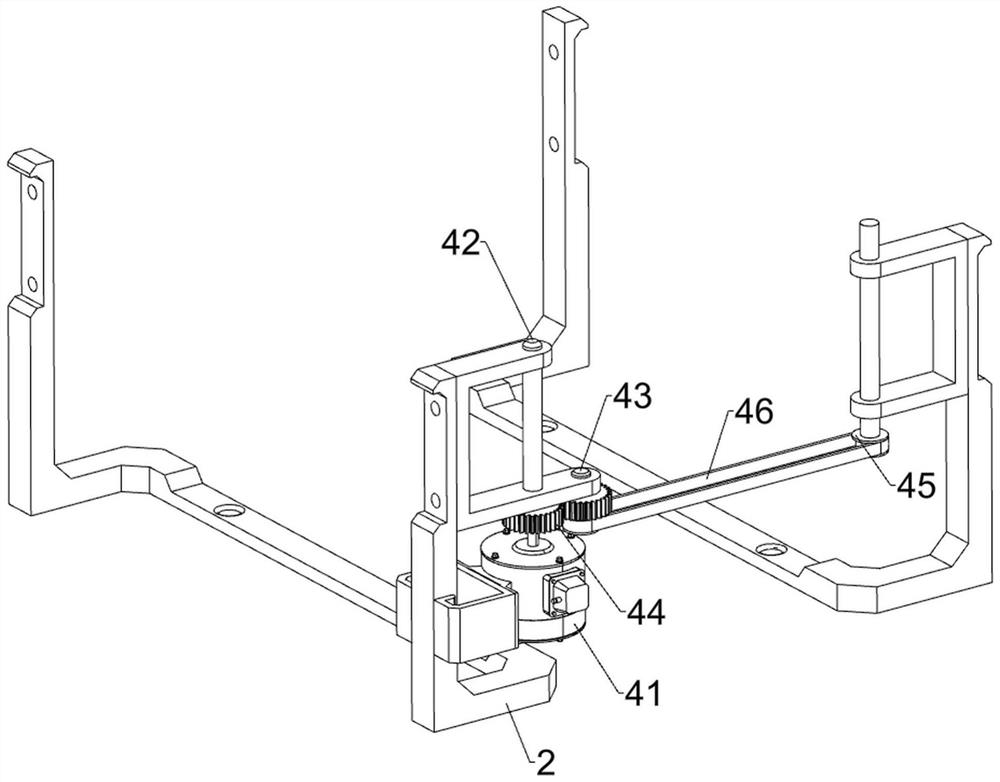

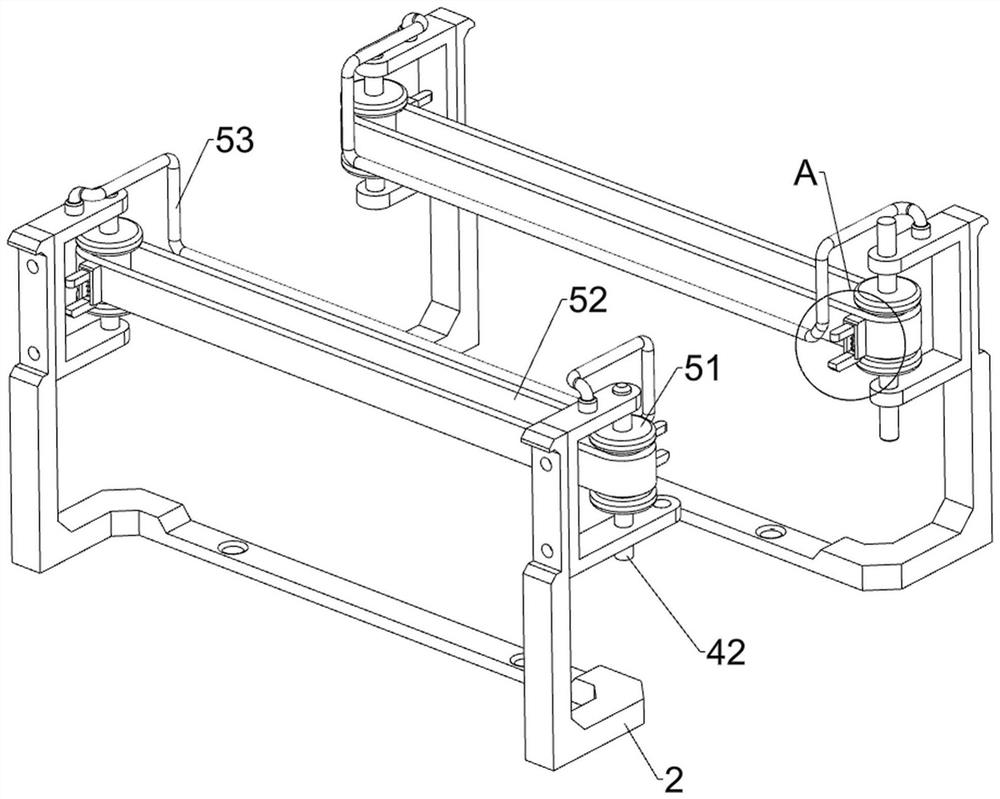

[0027] Such as Figure 1-Figure 5 As shown, a deodorizing device for fabric processing includes a base 1, a support frame 2, a collection frame 3, a driving assembly 4, a conveying assembly 5, a clamping assembly 6 and a spraying assembly 7, and the left and right sides of the base 1 pass through Bolts are fixedly connected with a support frame 2, a collection frame 3 is provided on the rear side of the base 1, a drive assembly 4 is provided between the front sides of the support frame 2, a delivery assembly 5 is provided on the left and right sides of the support frame 2, and a delivery assembly 5 is provided on the delivery assembly 5. A clamping assembly 6 is provided, and a spraying assembly 7 is arranged on the base 1 .

[0028] When it is necessary to deodorize the cloth, first place one end of the cloth between the clamping components 6 on both sides, and then control the driving component 4 to start working, the driving component 4 will drive the conveying component 5 ...

Embodiment 2

[0038] On the basis of Example 1, such asfigure 1 , Image 6 with Figure 7 As shown, a swing assembly 8 is also included, and the swing assembly 8 includes a push plate 81, a second gear 82, a guide plate 83, a rack 84, a second spring 85 and a push rod 86, and the first rotating rod 42 on the right side front The upper part is connected with a push plate 81, the second rotating rod 72 right side key is connected with a second gear 82, the upper part of the mounting plate 71 on the right is connected with a guide plate 83, and the guide plate 83 is slidably provided with a rack 84, the rack 84 Mesh with the second gear 82 , a second spring 85 is connected between the rack 84 and the guide plate 83 , a push rod 86 is connected to the right side of the rack 84 , and the push rod 86 cooperates with the push plate 81 .

[0039] When the first rotating rod 42 on the front right side rotates, it will also drive the push plate 81 to rotate, and when the push plate 81 rotates to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com