Self-locking drawbar and draw-bar box

A self-locking, tie-rod technology, applied in travel goods, applications, clothing, etc., can solve the problems of complex structure and production process, and many parts of the tie-rod structure, so as to enhance the overall design sense of appearance, simple structure and simplified production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

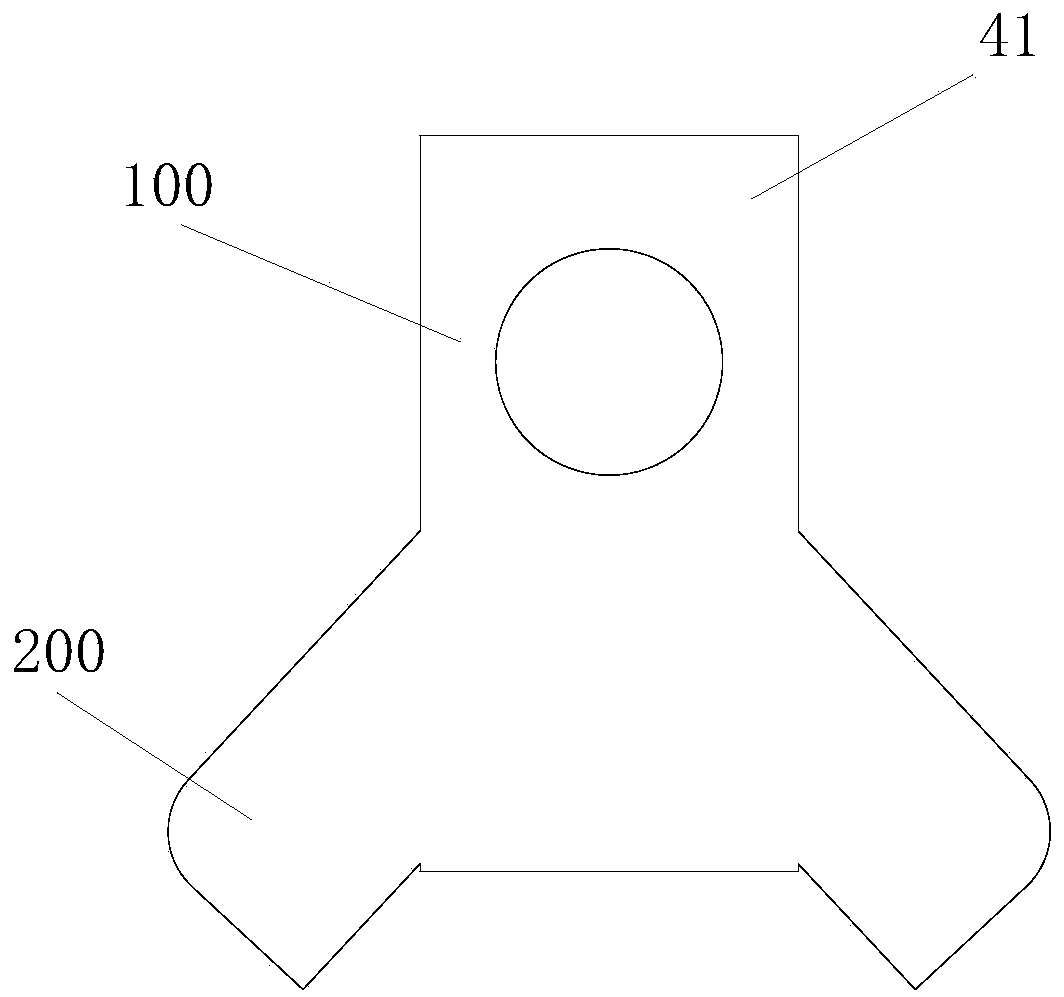

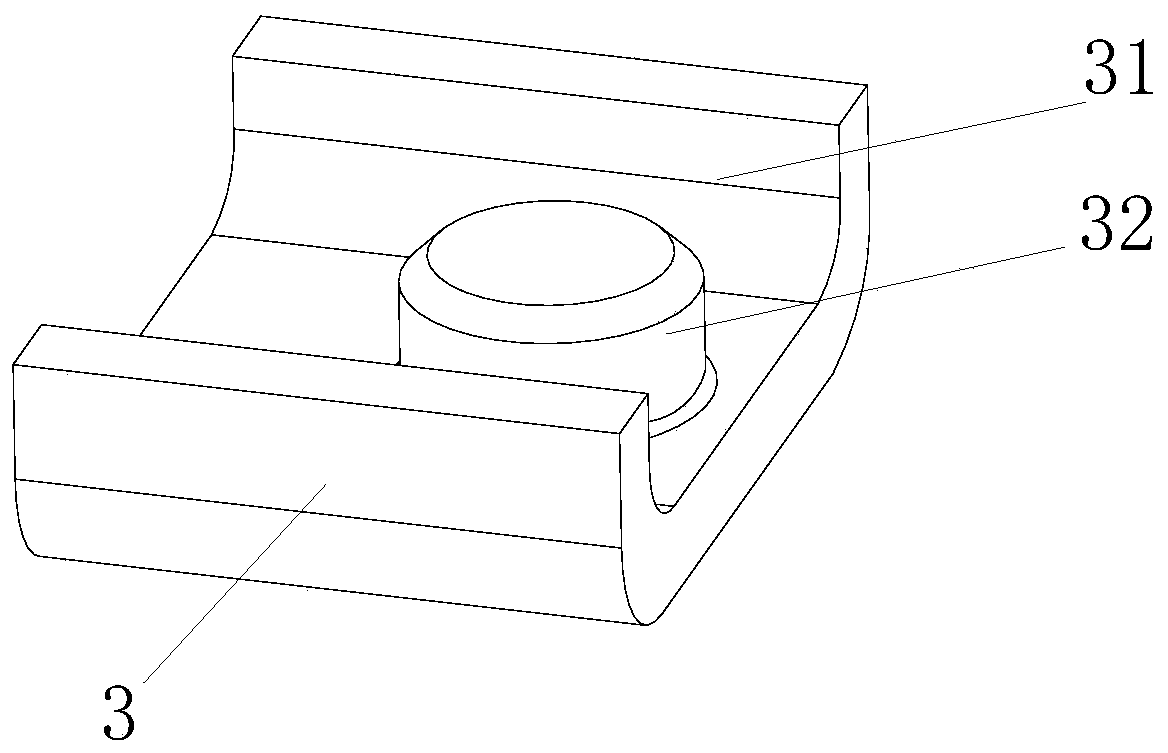

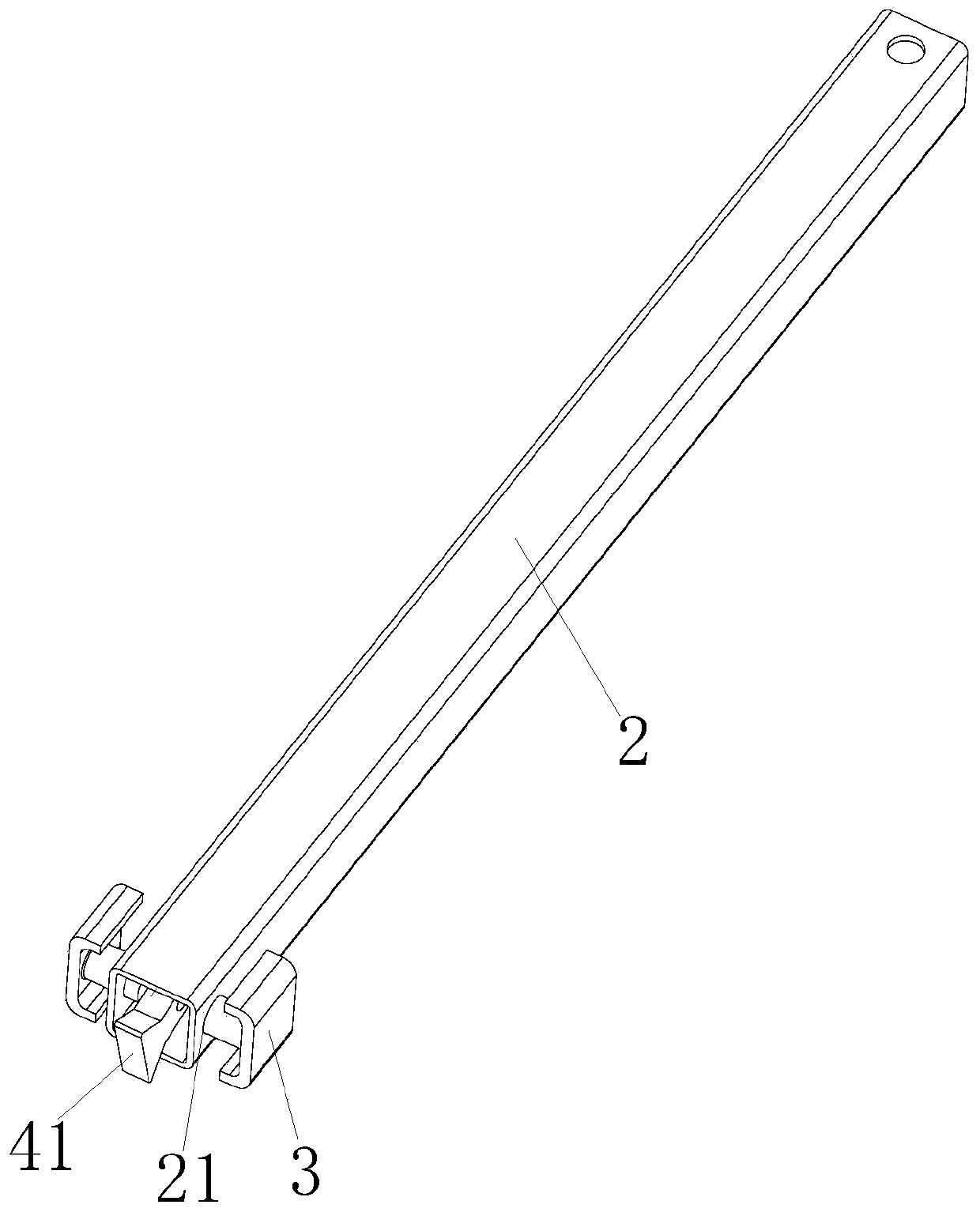

[0035] Figure 1 to Figure 6 The first preferred embodiment of the self-locking pull rod of the present invention is shown, which includes an outer tube 1 and an inner tube 2 sleeved in the outer tube 1, the outer tube 1 is fixed, the inner tube 2 is pulled up and down, and the side of the outer tube 1 There are several locking holes 11 for locking the outer tube, for the convenience of explanation, in this embodiment, the locking holes 11 for locking the locking of the outer tube are set on the right side of the outer tube 1 as an example. The bottom of the inner tube 2 is fixed with a stop buckle 41. The lower part of the stop buckle 41 is heavier than the upper part. The stop buckle 41 includes a fixed part 100 on the upper part and a protrusion on the same side as the lock hole 11 of the outer tube stop buckle at the lower part. Part 200, the fixing part 100 is provided with a through hole, and the stop buckle 41 is installed on the bottom of the inner tube 2 through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com