Outdoor projection film and preparation method therefor

A projection film, outdoor technology, applied in the direction of pressure-sensitive film/sheet, film/sheet release liner, film/sheet adhesive, etc. Affect the projection effect and other problems, to achieve the effect of good resistance to rain erosion, not easy to age and fall off, and good resistance to solar radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example 1:

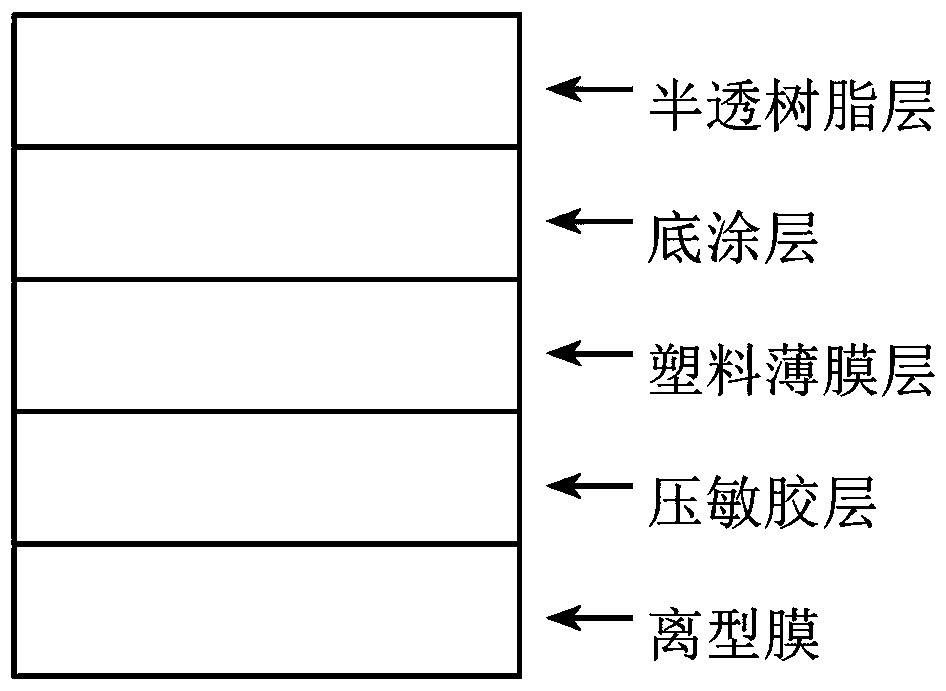

[0029] Such as figure 1 As shown, an outdoor projection film includes a plastic film layer, the surface of the plastic film layer is provided with a primer layer, and the surface of the primer layer is provided with a semi-permeable resin layer; the other surface of the plastic film layer is provided with a pressure-sensitive adhesive layer , The surface of the pressure-sensitive adhesive layer is provided with a release film layer. The semi-permeable resin layer is made of the following raw materials: 100g water-based polyurethane, 50g solvent deionized water, 4g cosolvent ethylene glycol butyl ether, curing agent bio-based oleyl alcohol and anion modified HDI polyisocyanate 2g, 1-5μm silica Particles 5g and 1-5μm titanium dioxide particles 5g.

[0030] Among them, the plastic film layer is polyethylene terephthalate film with a thickness of 20 μm; the primer layer is polyurethane, and the thickness of the primer layer after drying and curing is 1 μm; the thic...

Example Embodiment

[0031] Example 2:

[0032] An outdoor projection film includes a plastic film layer. The surface of the plastic film layer is provided with a primer layer, and the surface of the primer layer is provided with a semi-permeable resin layer; the other surface of the plastic film layer is provided with a pressure sensitive adhesive layer, which is pressure sensitive The surface of the glue layer is provided with a release film layer. The semi-permeable resin layer is made of the following raw materials: 100g of water-based polyurethane, 50g of solvent deionized water, 8g of cosolvent ethylene glycol butyl ether, curing agent bio-based oleyl alcohol and anionic modified HDI polyisocyanate 3g, 1-5μm silica 10g of particles and 10g of 1-5μm titanium dioxide particles.

[0033] Among them, the plastic film layer is a polyimide film with a thickness of 100 μm; the primer layer is polycarbonate, and the thickness of the primer layer after drying and curing is 0.8 μm; the thickness of the se...

Example Embodiment

[0034] Example 3:

[0035] An outdoor projection film includes a plastic film layer. The surface of the plastic film layer is provided with a primer layer, and the surface of the primer layer is provided with a semi-permeable resin layer; the other surface of the plastic film layer is provided with a pressure-sensitive adhesive layer. The surface of the glue layer is provided with a release film layer. The semi-permeable resin layer is made of the following raw materials: 100g water-based polyurethane, 50g solvent deionized water, 5g cosolvent ethylene glycol butyl ether, curing agent bio-based oleyl alcohol and anionic modified HDI polyisocyanate 4g, 1-5μm silica 15 g of particles and 15 g of titanium dioxide particles of 1-5 μm.

[0036] Among them, the plastic film layer is a polyethylene terephthalate film with a thickness of 15 μm; the primer layer is polyurethane, and the thickness of the primer layer after drying and curing is 0.5 μm; the thickness of the semipermeable resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap