Patents

Literature

141results about How to "Not easy to age and fall off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion-resistant colored film of austenite thin-wall stainless steel pipe and preparation method of corrosion-resistant colored film

InactiveCN104593765ATightly boundNot easy to age and fall offSuperimposed coating processThin walledCorrosion resistant

The invention discloses a corrosion-resistant colored film of an austenite thin-wall stainless steel pipe. A colored layer of the corrosion-resistant colored film of the austenite thin-wall stainless steel pipe is coated on a passivation layer and has a structure with two or more layers; the passivation layer is directly connected with the surface of an austenite thin-wall stainless steel pipe substrate material; and the color of the colored layer is changed along with the thickness change of the colored layer. The invention also discloses a method for preparing the corrosion-resistant colored film of the austenite thin-wall stainless steel pipe, and the method comprises the steps of pretreatment, acid cleaning, passivation, coloring, film fixing and sealing. The corrosion-resistant colored film of the austenite thin-wall stainless steel pipe not only has relatively strong corrosion resistance, wear resistance and stain resistance, but also is varied in color, uniform and bright in color and luster, difficult to change color and good in color reproducibility; and meanwhile, the method for preparing the corrosion-resistant colored film of the austenite thin-wall stainless steel pipe is simple in process and easy to operate.

Owner:SHENZHEN MINLE PIPE IND

Coating method of woven bag

The invention provides a coating method of a woven bag. The method comprises the following steps of: weaving warps and wefts made of fibrous material into a cylindrical fibrous braid on a circular weaving machine; then spraying coatings which are prepared on site on the inside of the braid to form a liner, wherein the coatings comprise the following components in parts by mass: 11-15 parts of ethylene-vinyl acetate copolymer, 26-35 parts of polyvinyl alcohol, 5-15 parts of isocyanate, 5-15 parts of polyether glycol, and 5-12 parts of diethyl methyl benzene diamine; and then drying to obtain an inner sprayed woven bag product.

Owner:QINGDAO BAIZHONG CHEM TECH

Preparing method for lamp packaging conductive adhesive

InactiveCN106497472AMeet the use requirementsImprove performanceEpoxy resin adhesivesElectrically-conducting adhesivesEpoxyAdhesive

The invention discloses a preparing method for lamp packaging conductive adhesive, and belongs to the technical field of adhesive preparation. The method comprises the steps of adopting fig branches and roots as raw materials, releasing stickum therein by enzymolysis, and obtaining high-viscosity fig tree syrup by vacuum concentration; then blending the tree syrup and conductive carbon black and obtaining electrocondution slurry under the effect of coupling reagent, extracting antioxidant fluid from rosemary residue, compounding the antioxidant fluid with epikote and the electrocondution slurry and obtaining conducting resin component A, using curing agent to prepare component B, and obtaining the packaging conductive adhesive by performing compounding proportionally. The method utilizes high-viscosity active radical groups in the fig tree syrup to improve the number of chemical bonds between the adhesive and matrix, improves binding force so as to ameliorate the problem of the low bonding strength of traditional adhesive, increases the ageing resistance of the adhesive by the antioxidant fluid of the rosemary, and makes up for the defect that the traditional conducting resin gets aged and sheds easily. The compounding of the two components greatly shortens the curing time of the adhesive. The preparing method for lamp packaging conductive adhesive has a good application prospect.

Owner:CHANGZHOU DINGRI ENVIRONMENTAL PROTECTION TECH

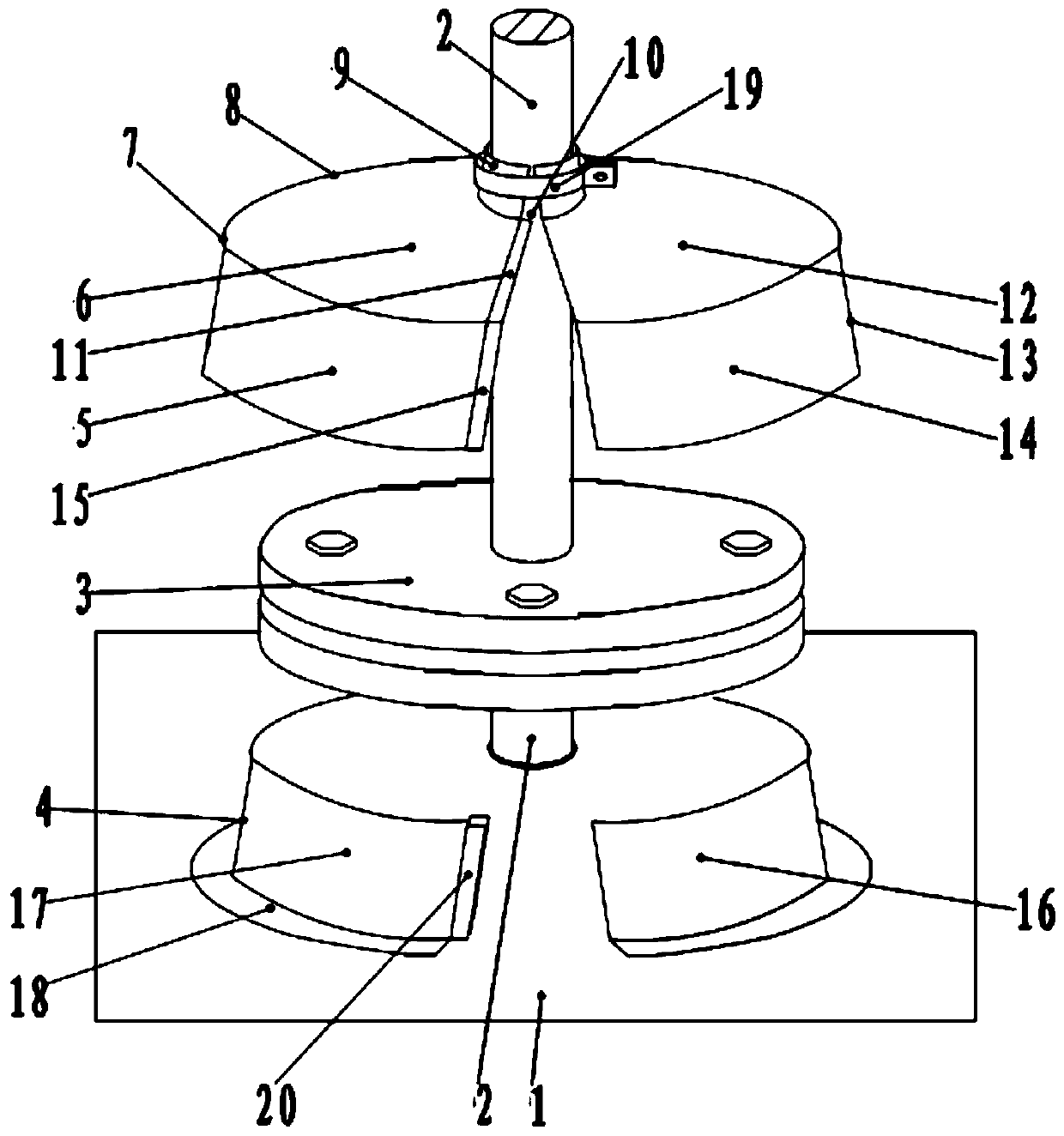

Isolation switch rainproof cover

PendingCN109872915AHigh secondary recovery rateAvoid Waterlogging ProblemsAir-break switch detailsEngineeringHigh pressure

The invention discloses an isolation switch rainproof cover which comprises a transmission connection rod passing through a high-voltage isolation switch mechanism case and a flange plate on the transmission connection rod. A rainproof cap is arranged on the transmission connection rod above the flange plate; the rainproof cap comprises a rainproof cap body both left and right parts can hold the transmission connection rod the rainproof cap comprises an umbrella-shaped cap, a bushing and a lower skirt; the transmission connection rod passes through the bushing and the umbrella-shaped cap; therainproof cap is fixed on the transmission connection rod by a hoop to synchronously rotate; a sleeve is arranged on the transmission connection rod below the flange plate; and the sleeve is arrangedon the high-voltage isolation switch mechanism case. The isolation switch rainproof cover is ingenious in structure; in an up-and-down staggered mode, rainwater cannot be accumulated in a large area on a top cover of the high-voltage isolation switch mechanism case so as to avoid corrosion and jamming of a transmission part, which are caused by rainwater pouring, and prolong the service life of arubber material sealing part; the spliced structure adopts a combined mode so as to facilitate disassembling and assembling; a material secondary recovery rate is high; and the isolation switch rainproof cover is an efficient and reliable outdoor high-voltage electrical equipment protection device.

Owner:STATE GRID CORP OF CHINA +1

Anti-cracking environment-friendly waterproof bonding material for roof and preparation method thereof

InactiveCN108329762AImprove protectionImprove impact performanceAntifouling/underwater paintsPaints with biocidesFiberCrack resistance

The invention discloses an anti-cracking environment-friendly waterproof bonding material for a roof and a preparation method thereof. The bonding material is prepared from the following raw materialsin parts by weight: 20 to 30 parts of ethylene-vinyl acetate copolymers, 5 to 7 parts of anti-cracking fiber, 10 to 15 parts of inorganic gel, 7 to 9 parts of nanometer polymers, 3 to 5 parts of polymer emulsion, 4 to 6 parts of polyvinyl alcohol resin, 1 to 2 parts of dispersing agents, 8 to 12 parts of waterproof filling agents, 0.2 to 0.6 part of anti-foaming agents, 1 to 2 parts of antioxidants and 10 to 12 parts of organic solvents. The bonding material is used for a roof waterproof purpose, and has the excellent performance of cracking resistance, water flushing resistance, weather resistance and aging resistance; the attachment force and the anti-stretching performance are good; no toxicity and no harm exist; safety and environment-friendly effects are achieved; the one-step construction shaping is realized; meanwhile, the raw material ingredients are safe and reliable; no pollution is caused on the environment; raw materials can be easily obtained; the cost is low; the processis simple and clear; high practical values and good application prospects are realized.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

Coating method for inside of woven bag

The invention discloses a coating method of a woven bag. The coating method comprises the following steps of: firstly weaving warps and wefts made of fiber materials into a barrel-shaped fiber weaving layer on a circular weaving machine; then spraying paint prepared on site on the inner side of the weaving layer to form lining, wherein the paint comprises the following components in parts by weight: 16-20 parts of ethylene-vinyl acetate copolymer, 26-35 parts of polyving akohol, 30-45 parts of isocyanate, 20-35 parts of polyether glycol and 10-20 parts of diethyl methyl benzene diamine; and drying and obtaining a woven bag product with internal spraying.

Owner:湖南安福环保科技股份有限公司

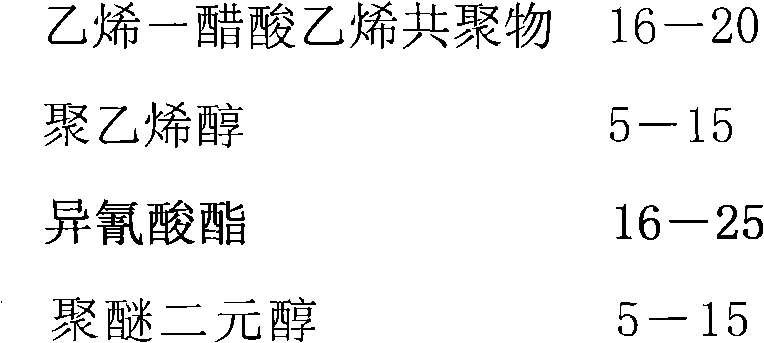

Internal coating technology for woven bag

InactiveCN103046354AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberPolyvinyl alcohol

The invention relates to an internal coating technology for a woven bag. The internal coating technology for the woven bag comprises the following steps: weaving warps and wefts made of fiber materials into a cylindrical fiber woven layer on a circular weaving machine; spraying coating prepared on site on the inner side of the woven layer to form lining, wherein the coating comprises the following components in part by weight: 16 to 20 parts of ethylene-vinyl acetate copolymer, 5 to 15 parts of polyvinyl alcohol, 16 to 25 parts of isocyanate, 5 to 15 parts of polyether glycol and 7 to 11 parts of diethyltoluenediamine; and drying to obtain the internally coated woven bag product.

Owner:青岛天鹅新材料织造有限公司

Flow for coating polyether glycol composition inside woven bag

InactiveCN102978951AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberPolymer science

The invention provides a flow for coating a polyether glycol composition inside a woven bag, comprising the following steps of: firstly, weaving warps and wefts made of fiber materials into a cylindrical fiber woven layer on a circular weaving machine; then spraying a coating which is prepared in the field at the inner side of a woven layer to form a lining, wherein the coating comprises the following components in parts by mass: 16-20 parts of ethylene-vinyl acetate copolymer, 16-25 parts of polyvinyl alcohol, 16-25 parts of isocyanate, 26-35 parts of polyether glycol and 7-11 parts of diethyl methyl benzene diamine; and drying to obtain an internally sprayed woven bag product.

Owner:QINGDAO PENGHAI SOFT CO LTD

Woven bag coating method

InactiveCN102978942AImprove efficiencyHigh strengthFibre typesMonocomponent polyolefin artificial filamentFiberPolyvinyl alcohol

The invention provides a woven bag coating method. The method comprises the steps of firstly weaving warps and wefts, which are made of fiber materials, to prepare a tubular fiber woven layer on a circular weaving machine, then spraying a coating prepared on site on the inner side of the woven layer to form a lining and obtaining the internally sprayed woven bag product after drying, wherein the coating comprises the following components in parts by weight: 11-15 parts of ethylene-vinyl acetate copolymers, 46-55 parts of polyvinyl alcohol, 10-14 parts of isocyanate, 5-15 parts of polyether diol and 5-12 parts of diethyltoluenediamine.

Owner:QINGDAO BAIZHONG CHEM TECH

Method for coating woven bag

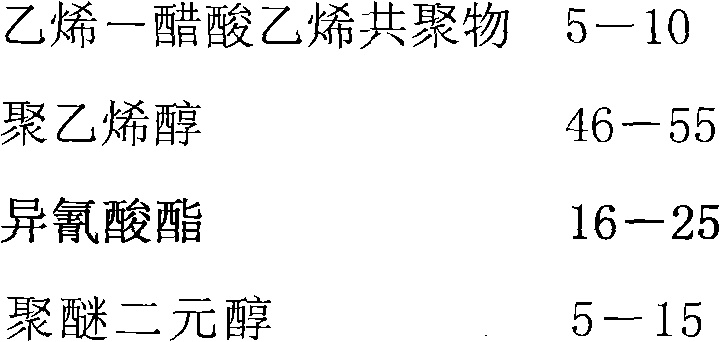

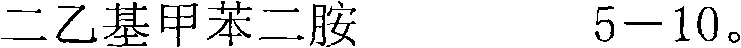

The invention discloses a method for coating a woven bag. The method comprises the following steps of: weaving warps and wefts made of a fiber material into a cylindrical fiber woven layer on a circular weaving machine; spraying a coating prepared in situ onto the inner side of the woven layer to form an inner lining, wherein the coating comprises the following components in parts by mass: 5-10 parts of ethylene-vinyl acetate copolymer, 5-15 parts of polyvinyl alcohol, 5-15 parts of isocyanate, 5-10 parts of polyether glycol and 5-10 parts of diethyl methyl benzene diamine; and drying to obtain an internally-sprayed woven bag product.

Owner:QINGDAO BAIZHONG CHEM TECH

Inner coating technology of woven bag

InactiveCN102965949AImprove efficiencyHigh strengthFibre typesMonocomponent polyolefin artificial filamentFiberMethyl benzene

The invention provides an inner coating technology of a woven bag. The inner coating technology comprises the following steps: weaving wraps and wefts, which are made of fiber materials, through a circular weaving machine, so as to obtain a cylindrical fiber woven layer; spraying the coating prepared at site on the inner side of the woven layer to form a liner, wherein the coating comprises the following components (mass): 5 to 10 parts of ethylene-vinyl acetate copolymer, 5 to 15 parts of polyving akohol, 16 to 25 parts of isocyanate, 36 to 45 parts of polyether glycol, and 5 to 10 parts of diethyl methyl benzene diamine; and drying, thus obtaining the inner-coated woven bag.

Owner:QINGDAO VLAND BIOTECH GRP

Woven bag coating method

InactiveCN102978919AImprove efficiencyHigh strengthFibre typesMonocomponent polyolefin artificial filamentFiberPolyvinyl alcohol

The invention provides a woven bag coating method. The method comprises the steps of firstly weaving warps and wefts, which are made of fiber materials, to prepare a tubular fiber woven layer on a circular weaving machine, then spraying a coating prepared on site on the inner side of the woven layer to form a lining and obtaining the internally sprayed woven bag product after drying, wherein the coating comprises the following components in parts by weight: 11-15 parts of ethylene-vinyl acetate copolymers, 5-15 parts of polyvinyl alcohol, 5-15 parts of isocyanate, 5-15 parts of polyether diol and 5-10 parts of diethyltoluenediamine.

Owner:QINGDAO BAIZHONG CHEM TECH

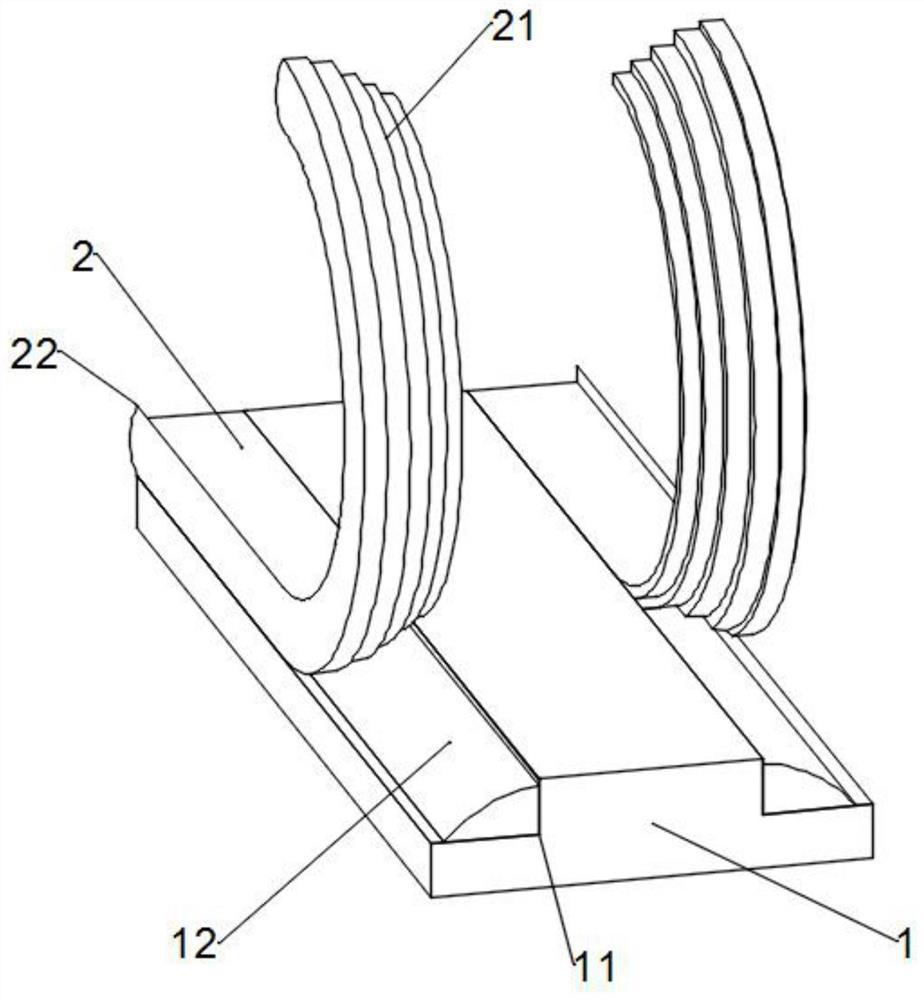

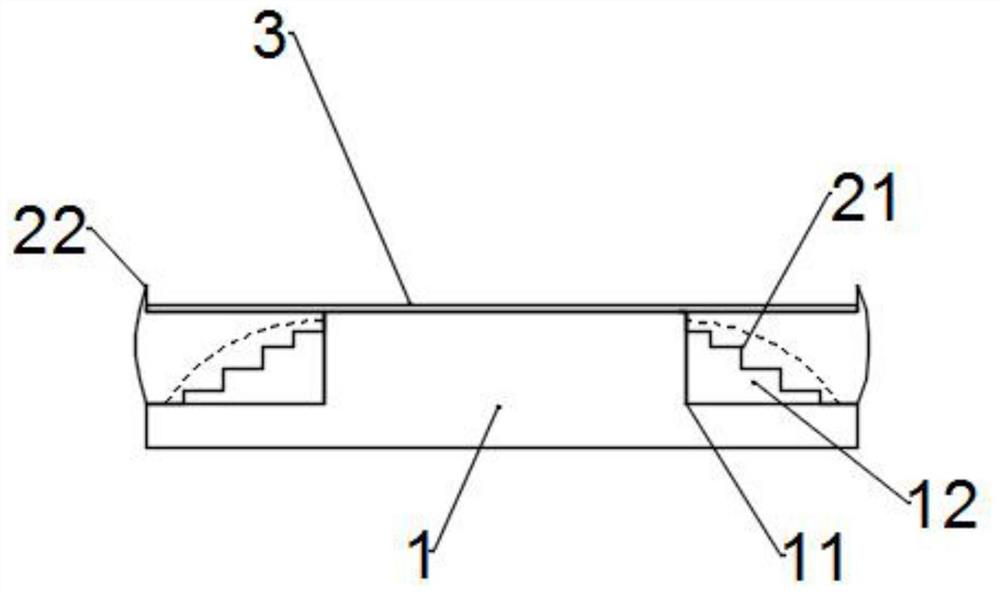

A kind of edge banding based on laser hot melting and preparation method thereof

The invention discloses an edge banding strip based on laser hot melting, comprising: a raised strip and a seam edge banding, hot-melt adhesive grooves are arranged on both sides of the top surface of the raised strip, and the hot-melt adhesive groove is coated with laser Hot-melt adhesive tape, the seam sealing edge is bonded in the hot-melt adhesive groove by laser hot-melt tape, the top surface of the seam sealing edge is equal to the top surface of the convex strip to form a pasting plane, and the pasting plane is coated with laser hot-melt adhesive Adhesive layer, the outer side of the top surface of the seam sealing is provided with the seam cover edge. The invention has a novel structure, and adopts seam sealing to effectively cover the seam formed after the edge sealing strip and the plate are bonded together, which is beautiful and practical, and has a better protective effect and formaldehyde barrier effect; the laser hot-melt adhesive technology is adopted, which is more effective than the traditional The pasting method is more firm, and it is not easy to age and fall off.

Owner:东莞市志尚装饰材料有限公司

Process for coating inside woven bag

InactiveCN103266487AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberMethyl benzene

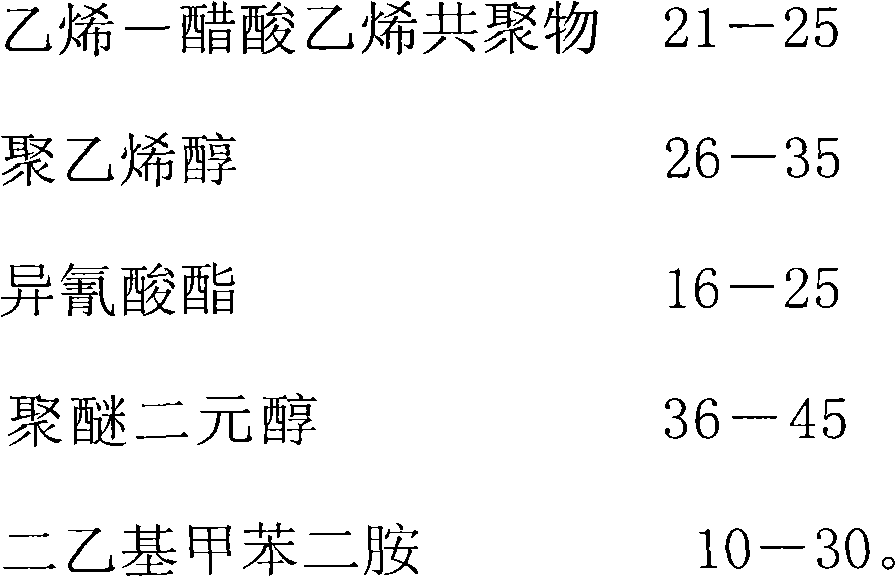

The invention discloses a process for coating inside a woven bag. The process comprises the following steps: firstly, weaving warps and wefts made of fiber materials into a cylindrical fiber braid on a circular weaving machine; then spraying a coating prepared on site on the inner side of the braid to form a liner, wherein the coating comprises the following components in parts by mass: 21-25 parts of ethylene-vinyl acetate copolymer, 26-35 parts of polyvinyl alcohol, 16-25 parts of isocyanate, 16-25 parts of polyether glycol and 10-30 parts of diethyl methyl benzene diamine; and drying to obtain the woven bag which is inside coated with the coating.

Owner:卜迪迪

Technology for coating inside woven bag

InactiveCN102978949AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberPolymer science

The invention discloses a technology for coating inside a woven bag. The technology comprises the following steps of: firstly, weaving a cylindrical fiber woven layer by using warps and wefts, both of which are made of fiber materials, on a circular weaving machine, then, spraying the coating prepared on site to the inner side of the woven layer to form a liner, and drying to obtain an inside-sprayed woven bag product, wherein the coating comprises the following components in parts by weight: 21-25 parts of ethylene-vinyl acetate copolymer, 26-35 parts of polyvinyl alcohol, 16-25 parts of isocyanate, 36-45 parts of polyether glycol, and 10-30 parts of diethyl toluenediamine.

Owner:QINGDAO PENGHAI SOFT CO LTD

Coating method of woven bag

The invention provides a coating method of a woven bag. The method comprises the following steps of: weaving warps and wefts made of fibrous material into a cylindrical fibrous braid on a circular weaving machine; then spraying coatings which are prepared on site on the inside of the braid to form a liner, wherein the coatings comprise the following components in parts by mass: 11-15 parts of ethylene-vinyl acetate copolymer, 36-45 parts of polyvinyl alcohol, 5-15 parts of isocyanate, 5-15 parts of polyether glycol, and 5-12 parts of diethyl methyl benzene diamine; and then drying to obtain an inner sprayed woven bag product.

Owner:QINGDAO BAIZHONG CHEM TECH

Coating technology for inner part of woven bag

InactiveCN103046371AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberPolyvinyl alcohol

A coating technology for the inner part of a woven bag comprises the following steps: first, weaving warps and wefts, which are made of fiber materials on a circular weaving machine, into a tube-shaped fiber weaving layer; then, spraying paint on the spot is sprayed on the inner side of the weaving layer to form a lining, wherein the paint comprises the following components in part by weight: 26 to 30 parts of ethylene-vinyl acetate copolymer, 46 to 55 parts of polyvinyl alcohol, 16 to 25 parts of isocyanate, 26 to 35 parts of polyether glycol, and 10 to 30 parts of diethyltoluenediamine; and after the lining is dried, obtaining a woven bag product with the spray-coated inner part.

Owner:QINGDAO SHENGHAN CHROMATOGRAPH TECH CO LTD

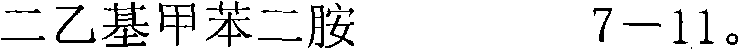

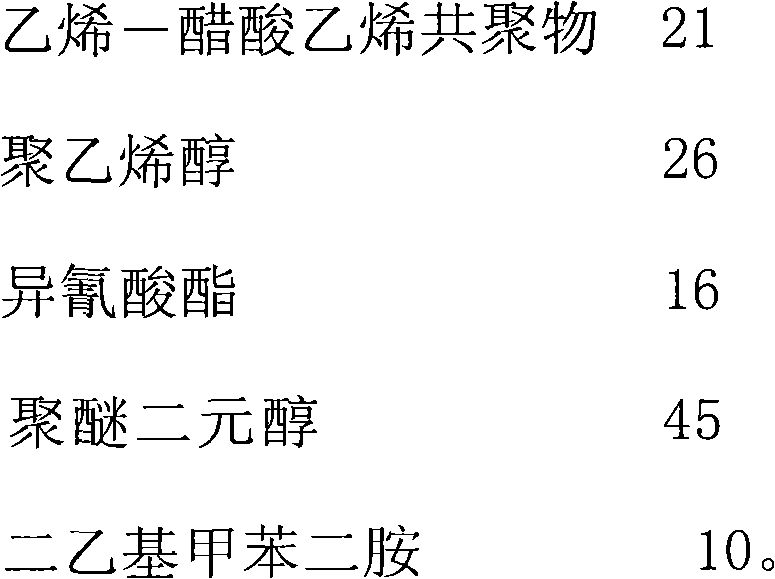

Internal coating method for woven bags

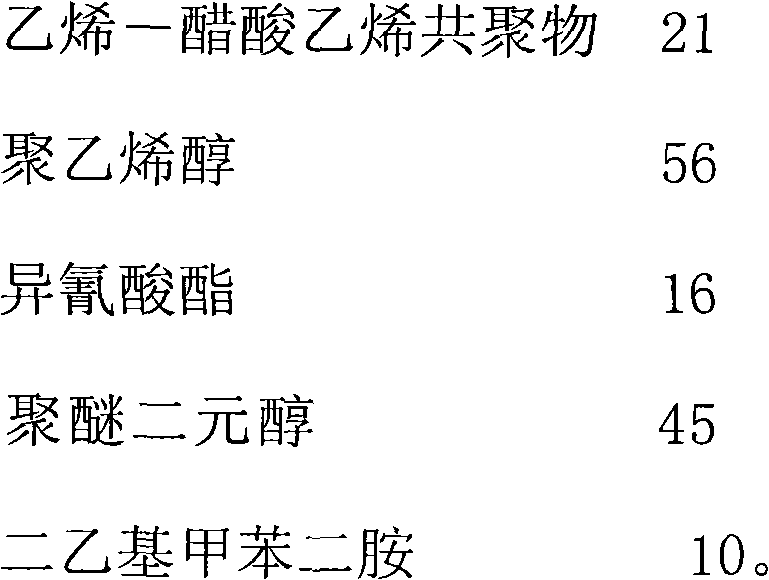

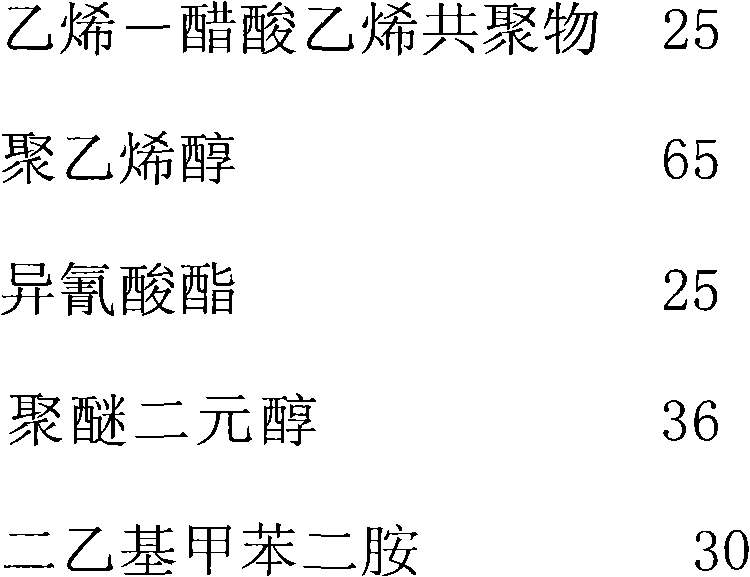

InactiveCN103046369AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberAdditive ingredient

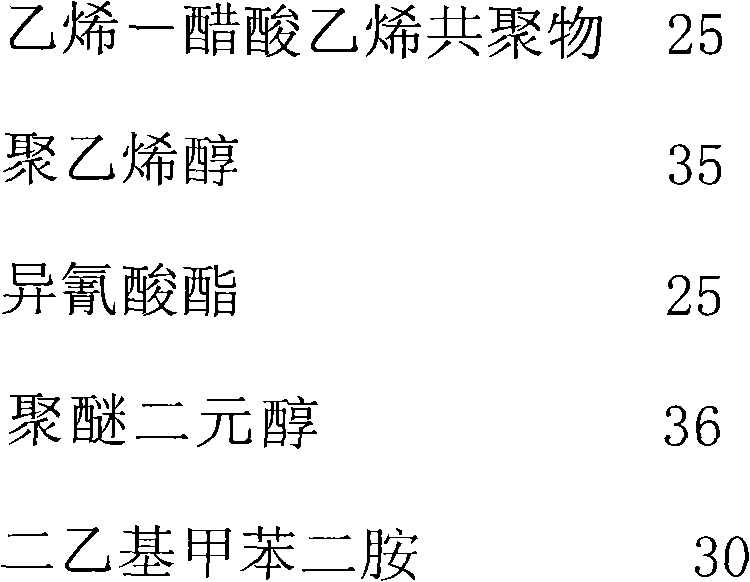

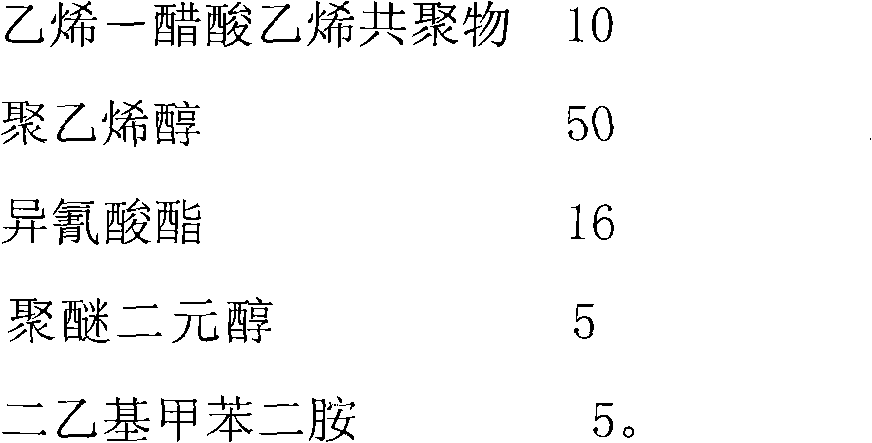

The invention relates to an internal coating method for woven bags. The method comprises the following steps: weaving warp and weft made of fiber materials into a tubular fiber woven layer on a circular weaving machine, then coating paint prepared on site onto the inner side of the woven layer to form a lining, and finally drying to obtain the inner-coating woven bag product. The pain comprises the following ingredients in part by weight (shown as the specifications).

Owner:QINGDAO SEACON WATER SERVICE TECH

Process for coating inside woven bag

InactiveCN102995442AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberMethyl benzene

The invention discloses a process for coating inside a woven bag. The process comprises the following steps of: firstly, weaving warps and wefts made of fiber materials into a cylindrical fiber braid on a circular weaving machine; then spraying a coating prepared on site on the inner side of the braid to form a liner, wherein the coating comprises the following components in parts by mass: 16-20 parts of ethylene-vinyl acetate copolymer, 16-25 parts of polyvinyl alcohol, 16-25 parts of isocyanate, 5-15 parts of polyether glycol and 7-11 parts of diethyl methyl benzene diamine; and drying to obtain the woven bag the inside of which is coated with the coating.

Owner:青岛天鹅新材料织造有限公司

Woven bag coating method

InactiveCN102978941AImprove efficiencyHigh strengthFibre typesMonocomponent polyolefin artificial filamentFiberPolyvinyl alcohol

The invention provides a woven bag coating method. The method comprises the steps of firstly weaving warps and wefts, which are made of fiber materials, to prepare a tubular fiber woven layer on a circular weaving machine, then spraying a coating prepared on site on the inner side of the woven layer to form a lining and obtaining the internally sprayed woven bag product after drying, wherein the coating comprises the following components in parts by weight: 11-15 parts of ethylene-vinyl acetate copolymers, 16-25 parts of polyvinyl alcohol, 5-15 parts of isocyanate, 5-15 parts of polyether diol and 5-12 parts of diethyltoluenediamine.

Owner:QINGDAO BAIZHONG CHEM TECH

Process of coating inside of woven bag by using isocyanate composition

InactiveCN102978947AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberPolyvinyl alcohol

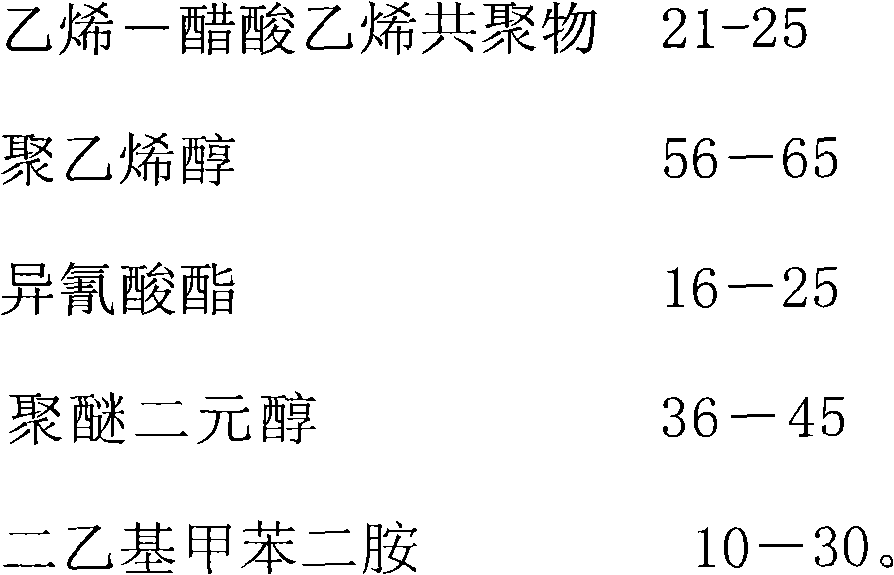

The invention discloses a process of coating the inside of a woven bag by using an isocyanate composition. The process comprises the following steps of: firstly, weaving a cylindrical fiber woven layer by using warps and wefts, both of which are made of fiber materials, on a circular weaving machine, then, spraying the coating prepared on site to the inner side of the woven layer to form a liner, and drying to obtain an inside-sprayed woven bag product, wherein the coating comprises the following components in parts by weight: 21-25 parts of ethylene-vinyl acetate copolymer, 56-65 parts of polyvinyl alcohol, 16-25 parts of isocyanate, 36-45 parts of polyether glycol, and 10-30 parts of diethyl toluenediamine.

Owner:QINGDAO PENGHAI SOFT CO LTD

Process for coating inner part of woven bag

InactiveCN103046375AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberPolyvinyl alcohol

A process for coating the inner part of a woven bag comprises the following steps: first, weaving warps and wefts, which are made of fiber materials on a circular weaving machine, into a tube-shaped fiber weaving layer, then, spraying paint prepared on the spot on the inner side of the weaving layer to form a lining, wherein the paint comprises the following components in part by weight: 26 to 30 parts of ethylene-vinyl acetate copolymer, 56 to 65 parts of polyvinyl alcohol, 16 to 25 parts of isocyanate, 26 to 35 parts of polyether glycol, and 10 to 25 parts of diethyltoluenediamine, and after the lining is dried, obtaining a woven bag product with the spray-coated inner part.

Owner:QINGDAO SHENGHAN CHROMATOGRAPH TECH CO LTD

Process for coating isocyanate composition to interior of woven bag

InactiveCN103015196AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberMethyl benzene

A process for coating isocyanate composition to the interior of a woven bag comprises the following steps: weaving warps and wefts, which are made from fiber material, into a cylindrical fiber braid layer on a circular weaving machine; coating material prepared on site is sprayed to the inner side of the braid layer to form an inner lining, wherein the coating material comprises the following components in part by mass: 16-20 parts of ethylene-vinyl acetate copolymer, 56-65 parts of polyvinyl alcohol, 16-25 parts of isocyanate, 26-35 parts of polyether glycol and 10-20 parts of diethyl methyl benzene diamine; and drying to obtain the woven bag product with the inner coating.

Owner:尚欣

Scheme for coating polyether glycol composition in woven bag

InactiveCN103015191AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingFiberAlcohol

The invention discloses a scheme for coating a polyether glycol composition in a woven bag. The scheme comprises the following steps: firstly, weaving warps and wefts made of a fiber material into a tubular fiber woven layer on a circular weaving machine; and subsequently spraying a coating prepared on site to the inner side of the woven layer so as to form a liner, wherein the coating comprises the following ingredients in parts by mass: 26-30 parts of ethylene-vinyl acetate copolymer, 5-15 parts of polyving alcohol, 16-25 parts of isocyanate, 16-25 parts of polyether glycol and 10-30 parts of diethyl toluenediamine, and drying so as to obtain an internally sprayed woven bag product.

Owner:张银香

Method for coating isocyanate composition in woven bag

InactiveCN103015201AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingDiamineIsocyanate

The invention provides a method for coating isocyanate composition in a woven bag. The method comprises the following steps: weaving warps and wefts, which are made of fiber materials, into a cylindrical fiber braid layer on a circular loom; then spraying coating, which is prepared on site, on the inner side of the braid layer to form an inner lining, wherein the coating comprises the following ingredients by mass: 11 to 15 parts of ethylene-vinyl acetate copolymer, 26 to 35 parts of polyvinyl alcohol, 16 to 25 parts of isocyanate, 16 to 25 parts of polyether glycol, and 5 to 12 parts of diethyl methyl benzene diamine; and drying to obtain the woven bag product sprayed with isocyanate composition inside.

Owner:张明

Coating method of woven bag

The invention provides a coating method of a woven bag. The method comprises the following steps of: weaving warps and wefts made of fibrous material into a cylindrical fibrous braid on a circular weaving machine; then spraying coatings which are prepared on site on the inside of the braid to form a liner, wherein the coatings comprise the following components in parts by mass: 5-10 parts of ethylene-vinyl acetate copolymer, 56-65 parts of polyvinyl alcohol, 5-15 parts of isocyanate, 5-15 parts of polyether glycol, and 6-8 parts of diethyl methyl benzene diamine; and then drying to obtain an inner sprayed woven bag product.

Owner:QINGDAO BAIZHONG CHEM TECH

Method for coating woven bag with isocyanate composition

InactiveCN102995420AImprove efficiencyHigh strengthFibre typesMonocomponent polyolefin artificial filamentFiberMethyl benzene

The invention discloses a woven bag coating method which comprises the following steps of: weaving warps and wefts made from fiber materials into a cylindrical fiber woven layer on a circular weaving machine; spraying the coating prepared on site onto the inner side of the woven layer to form a lining, wherein the coating comprises the following components in parts by mass: 21-25 parts of ethylene-vinyl acetate copolymer, 46-55 parts of polyvinyl alcohol, 35-55 parts of isocyanate, 20-40 parts of polyether glycol and 10-30 parts of diethyl methyl benzene diamine; and drying to obtain a product of inner-spraying woven bag.

Owner:QINGDAO BAIZHONG CHEM TECH

Woven bag inner coating method

InactiveCN102995413AImprove efficiencyHigh strengthFibre typesMonocomponent polyolefin artificial filamentFiberMethyl benzene

The invention discloses a woven bag coating method which comprises the following steps of: weaving warps and wefts made from fiber materials into a cylindrical fiber woven layer on a circular weaving machine; spraying the coating prepared on site onto the inner side of the woven layer to form a lining, wherein the coating comprises the following components in parts by mass: 16-20 parts of ethylene-vinyl acetate copolymer, 56-65 parts of polyvinyl alcohol, 30-45 parts of isocyanate, 20-35 parts of polyether glycol and 10-20 parts of diethyl methyl benzene diamine; and drying to obtain a product of inner-spraying woven bag.

Owner:QINGDAO BAIZHONG CHEM TECH

Process for coating polyether glycol composition in woven bag

InactiveCN102995427AImprove efficiencyHigh strengthFibre typesMonocomponent polyolefin artificial filamentFiberPolyvinyl alcohol

The invention provides a coating method of a woven bag. The method comprises the following steps of in sequence: weaving warps and wefts by a circular weaving machine to obtain a cylindrical fiber woven layer, wherein the warps and the wefts are manufactured by fiber materials; spraying a coating which is prepared at site on the inner side of the woven layer so as to obtain a lining, wherein the coating comprises the following components by mass: 26 to 30 parts of ethylene-vinyl-acetate copolymer, 56 to 65 parts of polyvinyl alcohol; 30 to 40 parts of isocyanate, 22 to 40 parts of polyether glycol, and 10 to 25 parts of diethyltoluenediamine; and then drying to obtain the internally-coated woven bag product.

Owner:QINGDAO BAIZHONG CHEM TECH

Scheme for coating inside of woven bag with isocyanate composition

InactiveCN103015208AImprove efficiencyHigh strengthFibre typesTextile treatment by spraying/projectingIsocyanate compoundEngineering

The invention discloses a scheme for coating the inside of a woven bag with an isocyanate composition. The scheme comprises the following steps that warps and wefts that are made of fiber materials are woven into a cylindrical fiber woven layer on a circular weaving machine; then, the inner side of the woven layer is sprayed and coated with paint prepared on site to form a lining; and the paint comprises the following components in parts by mass: 5-10 parts of ethylene-vinyl acetate copolymer, 5-15 parts of polyvinyl alcohol, 16-25 parts of isocyanate, 26-35 parts of polyether glycol, and 5-10 parts of diethyltoluenediamine. An inside sprayed and coated woven bag product is obtained after drying.

Owner:张银香

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com