Isolation switch rainproof cover

A technology of isolating switch and high-voltage isolating switch, applied in the direction of air switch components, etc., can solve the problems of large-scale power outage, box corrosion, economic loss, etc., achieve high secondary recovery rate, not easy to aging and fall off, and reduce construction difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

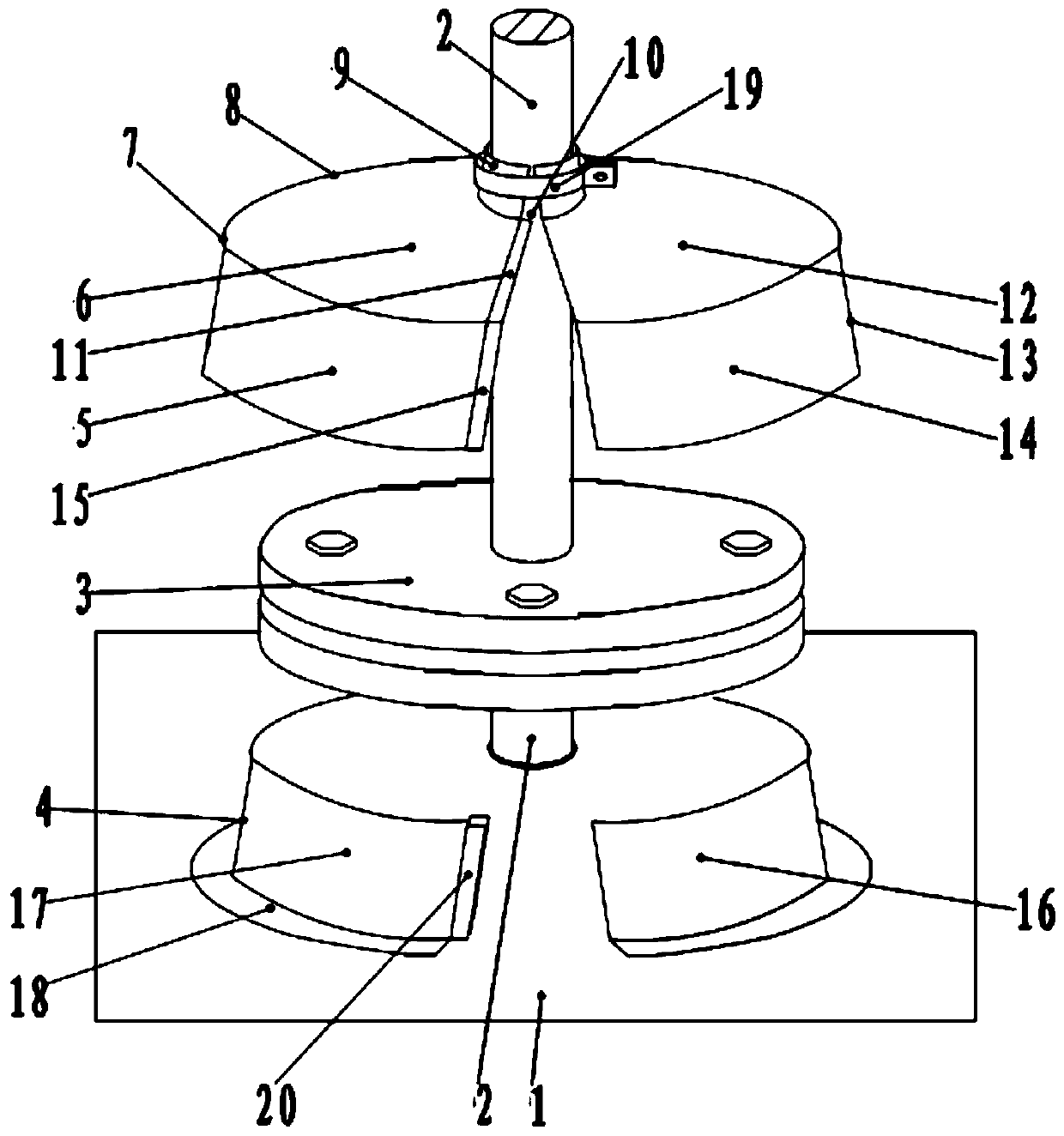

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0019] see figure 1 , the isolating switch rain cover of the present invention includes a transmission connecting rod 2 passing through the high-voltage isolating switch mechanism box 1 and a flange 3 on the transmission connecting rod 2, and a rainproof cover is arranged on the transmission connecting rod 2 above the flange 3. Cap 7, the diameter of the rainproof cap 7 is greater than that of the flange plate 3, and the rainproof cap 7 includes the rainproof cap body that the left and right parts can hug the transmission connecting rod 2. It includes an umbrella-shaped cap 8, a sleeve 9 and a lower skirt 13. The top of the umbrella-shaped cap 8 has an opening 10 communicating with the sleeve 9. The lower edge of the umbrella-shaped cap 8 is connected to the lower skirt 13. The umbrella-shaped cap 8 includes a first umbrella Type cap 6 and the second umbrella type ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com