Cracking device and ore extraction method

A technology for cracking and opening and closing valves, applied in the field of stone mining, can solve the problems of inability to accurately control gas pressure, complex structure of crackers, pollution of chemical reagents, etc., and achieve simple and convenient inflation, simple structure and high secondary recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present disclosure will be clearly and completely described below in conjunction with the accompanying drawings.

[0042]The fracturing device and method provided in the present disclosure can be used for expansion, cracking, and decomposition mining of ore bodies or ore substrates. It should be noted that rock-based hard and brittle materials have the obvious characteristic that the tensile strength is much smaller than the compressive strength. In view of this , the cracking device and method provided by the present disclosure is to overcome the tensile strength of the ore in the process of expanding and cracking the ore, so the difficulty of decomposition is greatly reduced, and the mining efficiency is improved accordingly.

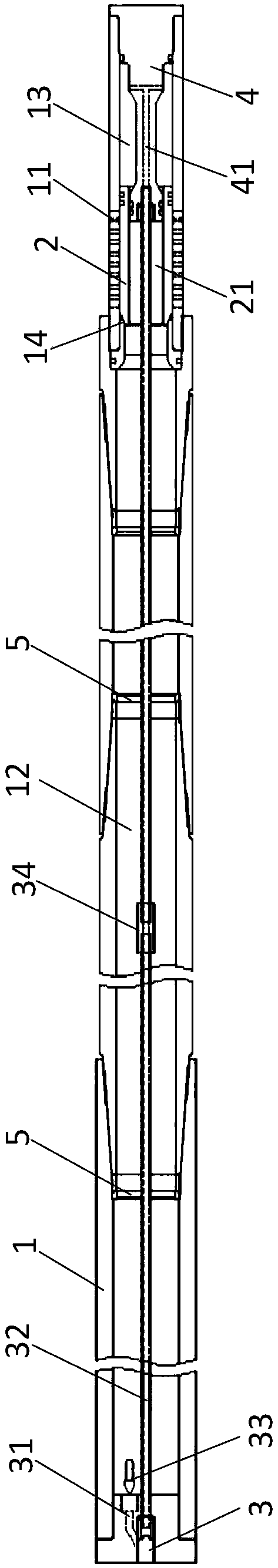

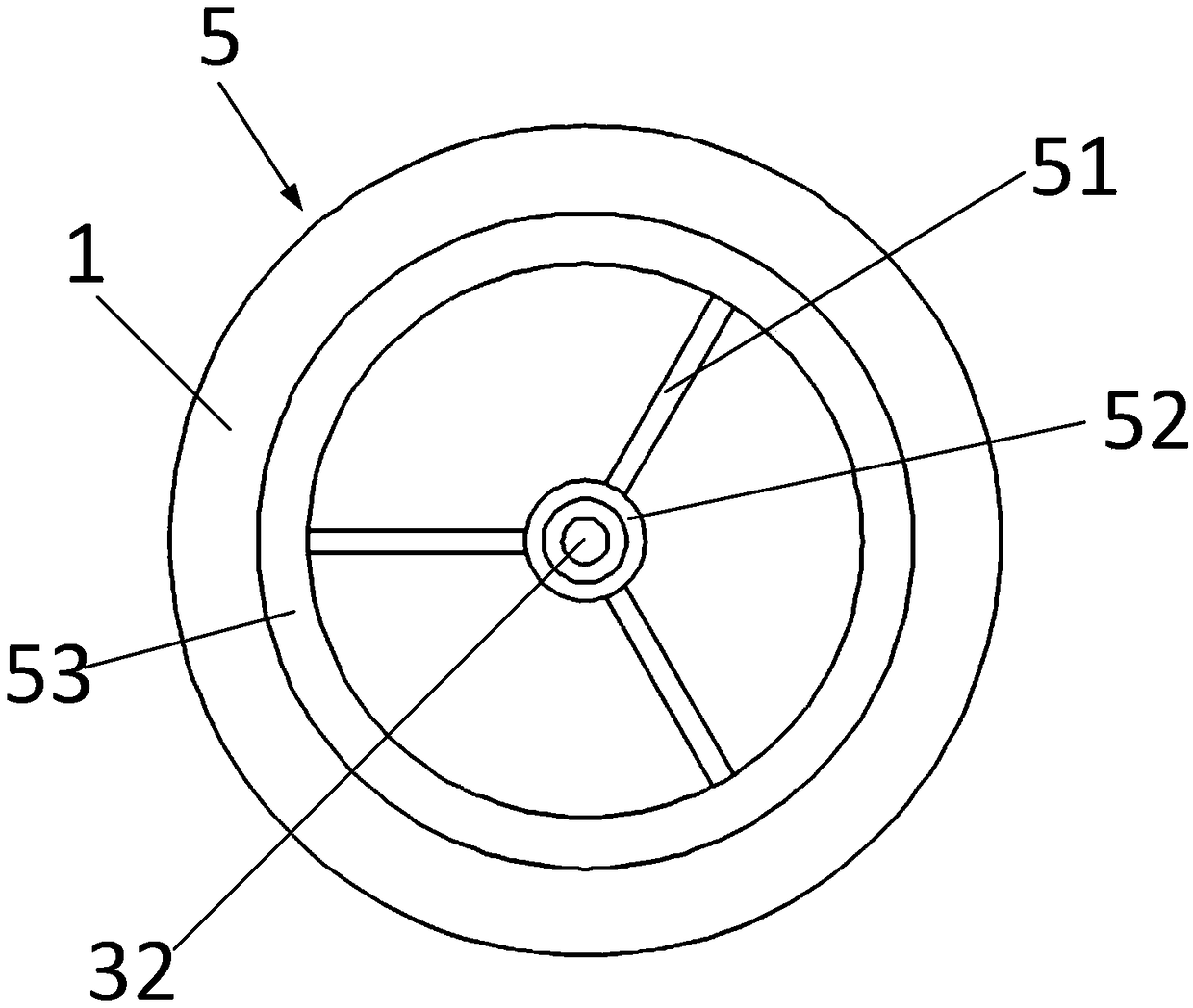

[0043] Such as figure 1 In one embodiment shown, the cracking device provided by the present disclosure includes a casing 1 , a switch valve 2 , an air inlet 31 , and a control air passage 32 . In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com