Aircraft tire sidewall rubber with good solar radiation resistance performance

A technology for aviation tires and solar radiation, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as poor solar radiation resistance, unsatisfactory thermal oxygen aging performance, flex cracking resistance, etc., and achieve storage Effects of long life, good solar radiation resistance, and low brittle temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

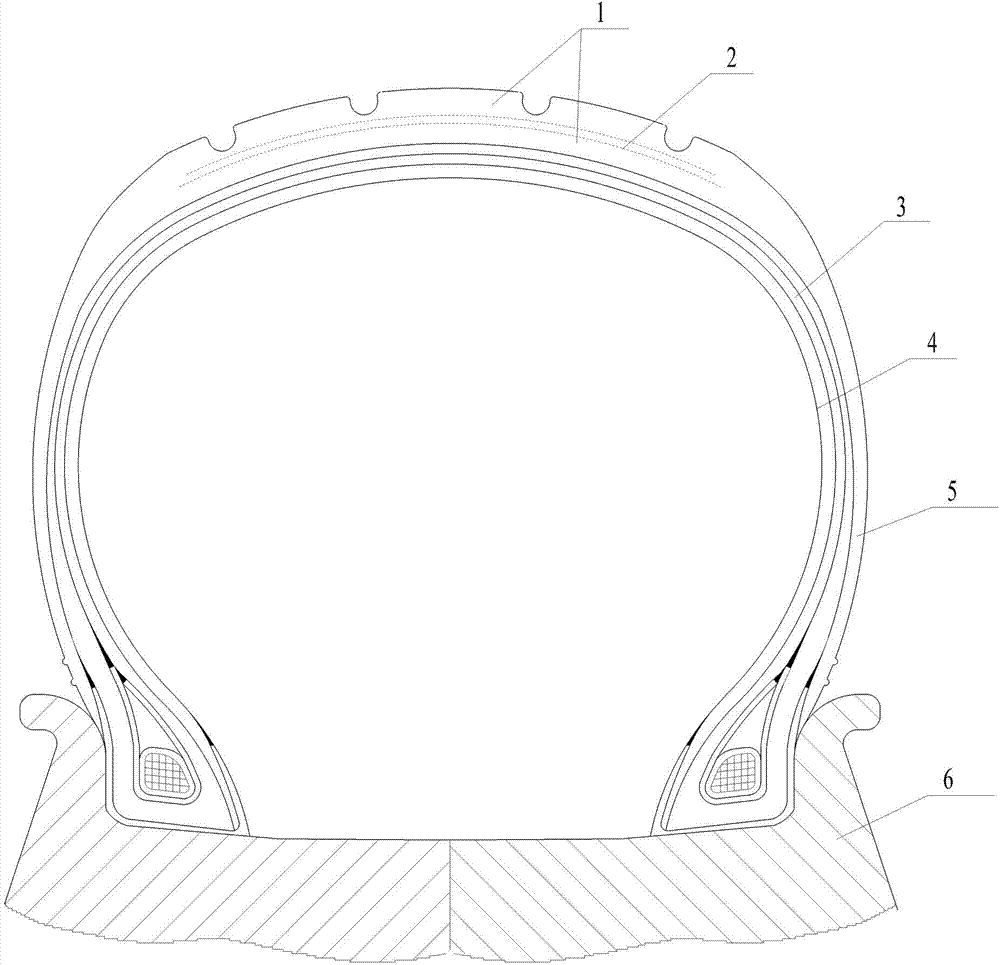

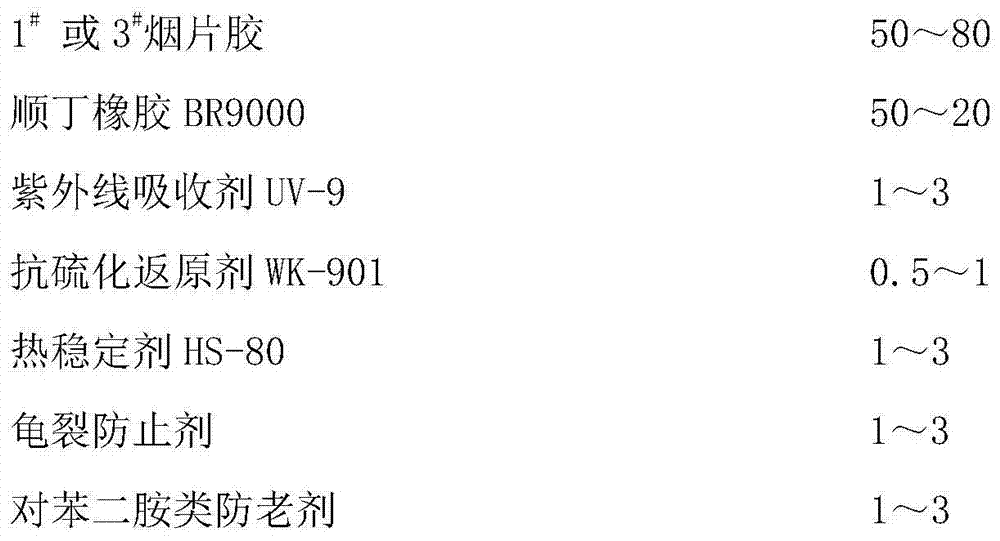

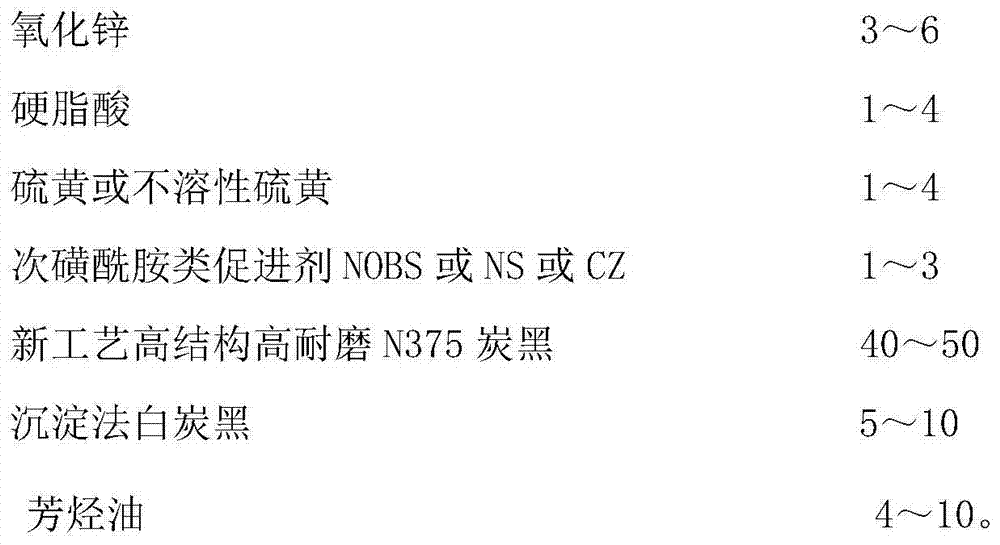

[0016] A kind of aviation tire sidewall rubber with good solar radiation resistance performance, as shown in Table 1, the formula of described sidewall rubber is made up of the raw material of following weight ratio:

[0017] Table 1 Three formulations of sidewall rubber

[0018] Raw material name

Recipe 1

Recipe 2

Recipe 3

1 # or 3 # Smoked sheet glue

60

70

80

Butadiene rubber BR9000

40

30

20

UV absorber UV-9

1

2

3

Anti-reversion agent WK-901

0.5

0.6

0.7

Heat Stabilizer HS-80

1.5

2

2.5

Anti-crack agent

2

2

2

p-phenylenediamine antioxidant

2

2.5

3

Zinc oxide

5

5

5

stearic acid

2

2.5

3

sulfur or insoluble sulfur

1.6

1.8

2.0

Sulfenamide Accelerators

1.6

1.4

1.2

N375 carbon black with new technology, high structure and high wear resistance

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap