Novel leaky cable fixing clamp

A leakage cable and fixture technology, which is applied in the installation of cables, cables in tunnels, electrical components, etc., can solve the problems of inability to meet the requirements of high and low temperature work, the deviation of overall strength and stability, etc., and achieve good anti-slip , Resistance to solar radiation, good high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

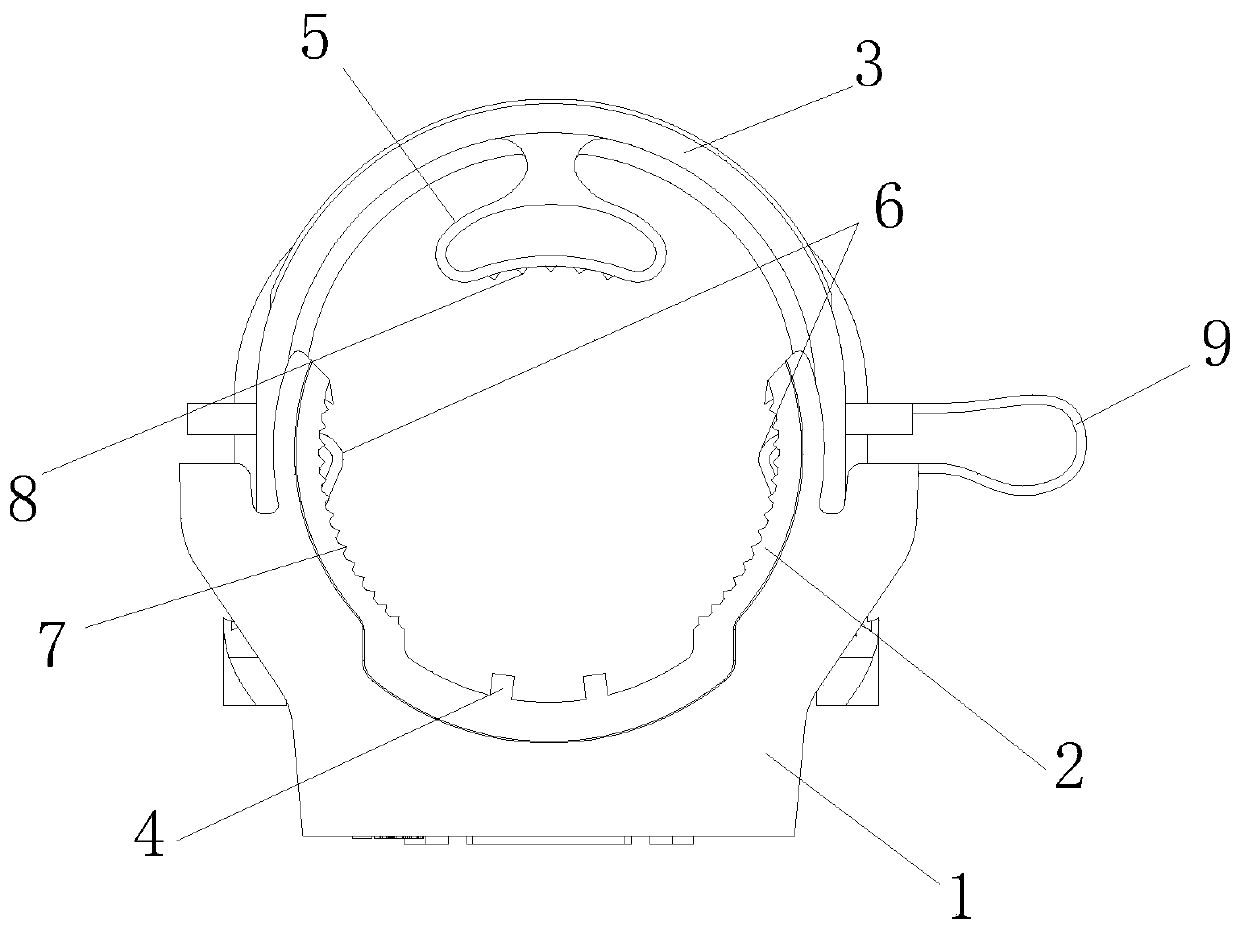

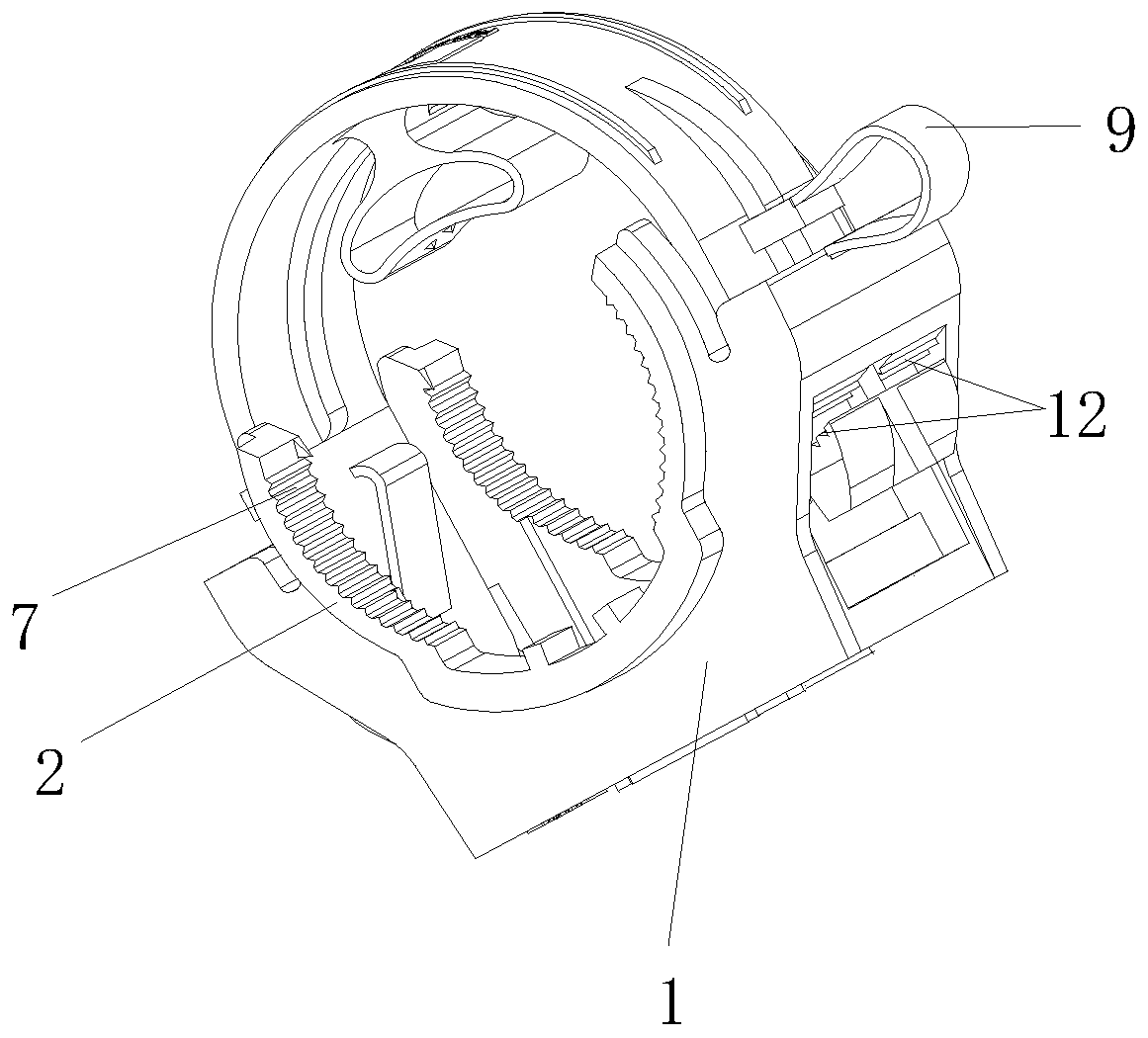

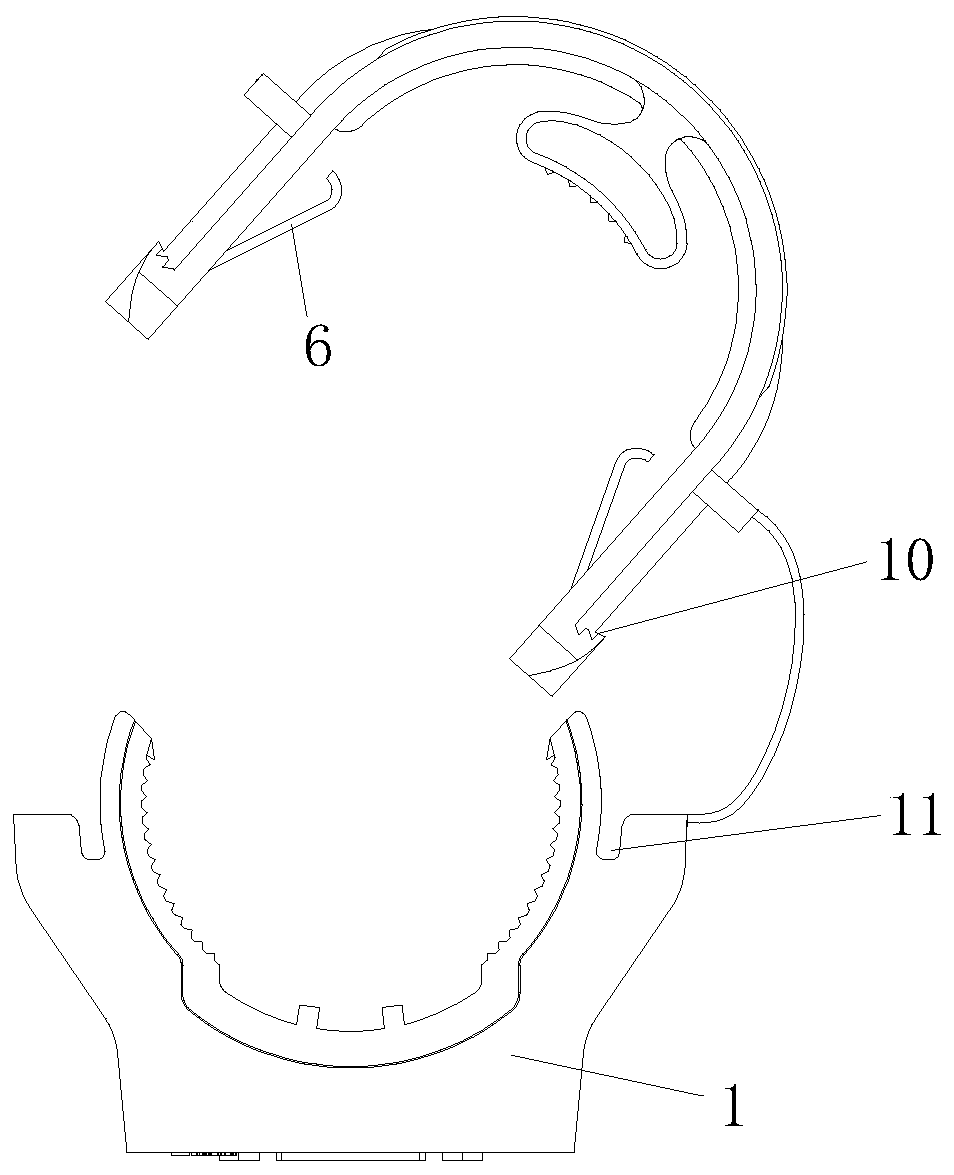

[0020] Such as figure 1 and figure 2 As shown, the novel leakage cable fixing jig of the present invention includes: a bottom plate 1, a clamping seat 2 and an upper cover plate 3 for clamping on the bottom plate 1 and the clamping seat 2; the clamping seat 2 is fixed on the bottom plate 1 And it is integrally formed with the bottom plate 1. In the specific embodiment of the present invention, the bottom plate, the clamping seat and the upper cover plate all have a "U" shape structure, and the two sides of the "U" shape are arc-shaped.

[0021] A positioning structure 4 is arranged at the bottom of the clamping seat 2, and the positioning structure can be designed as a positioning protrusion, a positioning column, etc. with positioning functions, and several saw teeth 7 are arranged on both si...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap