Waste plastic oil-refining device capable of quantitative addition of catalyst

A technology for waste plastics and oil refining equipment, applied in the field of oil refining, can solve problems such as low degree of automation, plastics are not easily degraded, and thick smoke is generated, and achieves the effect of improving the degree of automation, saving the number of motors, and increasing linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

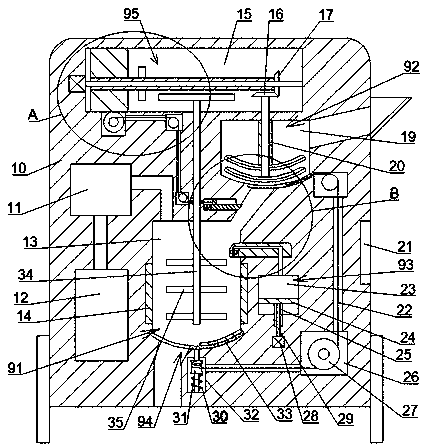

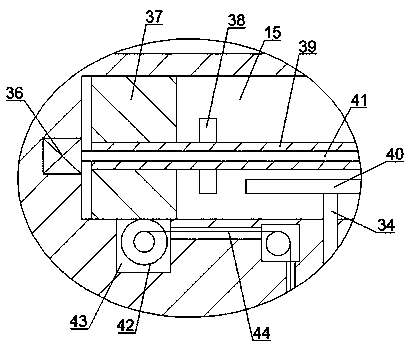

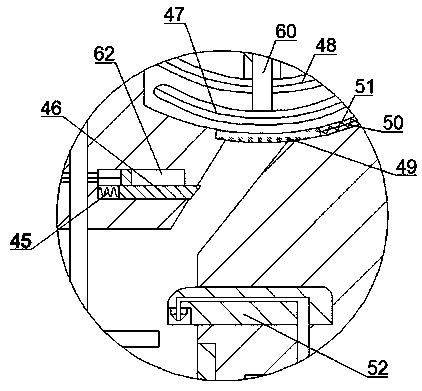

[0020] Combine below Figure 1-6 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0021] refer to Figure 1-6 , according to an embodiment of the present invention, a waste plastic refining device capable of quantitatively adding catalysts includes a main body 10 that can be fixed on the ground, and a crushing cavity 19 is opened in the main body 10, and a crushing cavity 19 is provided in the crushing cavity 19. There is a crushing mechanism 92, the crushing mechanism 92 includes a fixed sleeve 20 fixed on the top wall of the crushing chamber 19, the bottom surface of the fixed sleeve 20 is fixed with a first crushing knife 48, and the top of the crushing chamber 19 A power chamber 15 is opened, and a crushing shaft 60 extending up and down is arranged between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com