Method for producing mulberry essence

A production method and essence technology, which are applied in food science and other directions, can solve the problems of poor taste, difficult preservation, damage to mulberry aroma components and nutrients, etc., and achieve the effect of improving maturity and improving taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

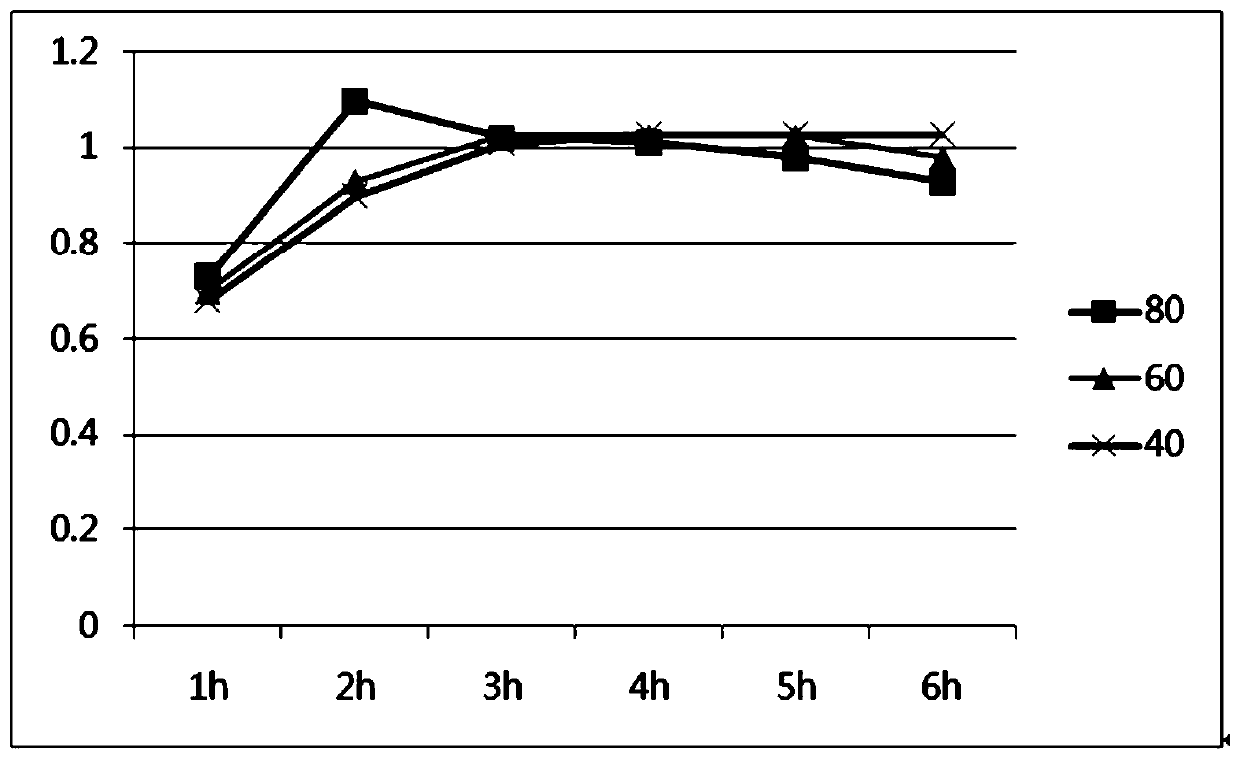

[0039] (1) Store the ripe mulberry fresh fruit after picking in an environment of 9° C. for 12 hours;

[0040] (2) carrying out liquid nitrogen homogenization with the mulberry processed in step (1);

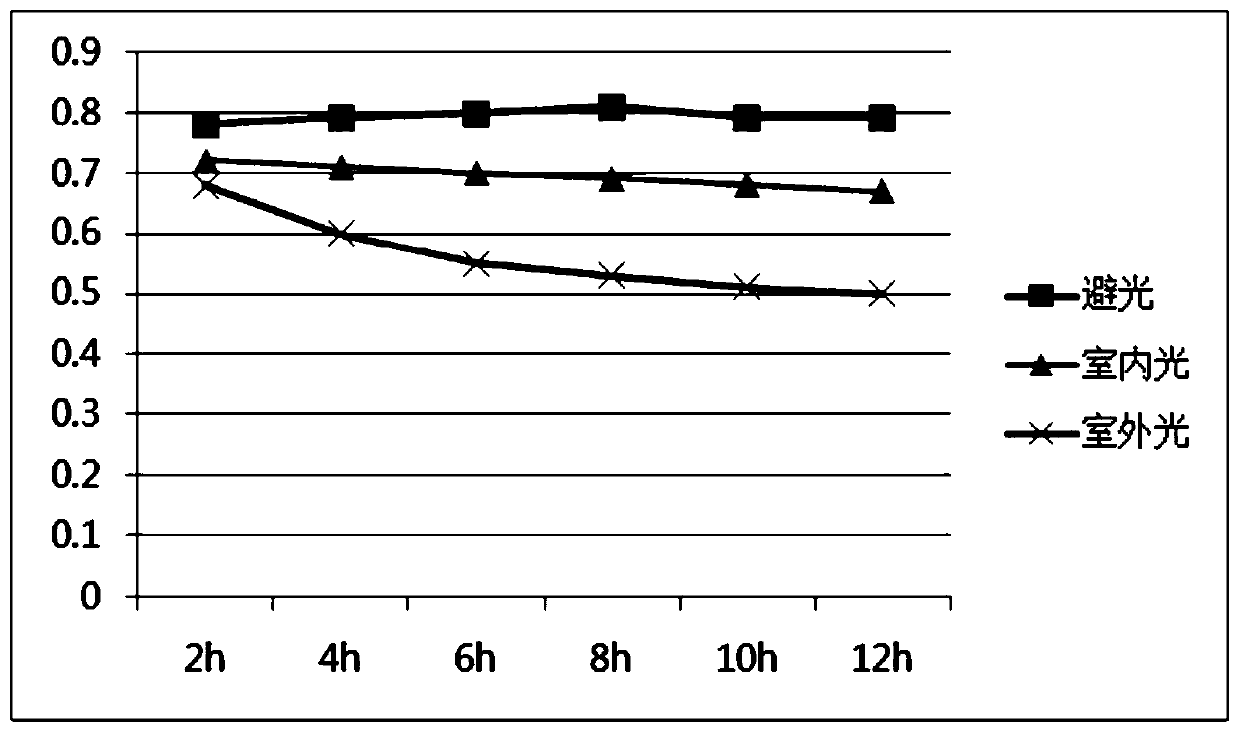

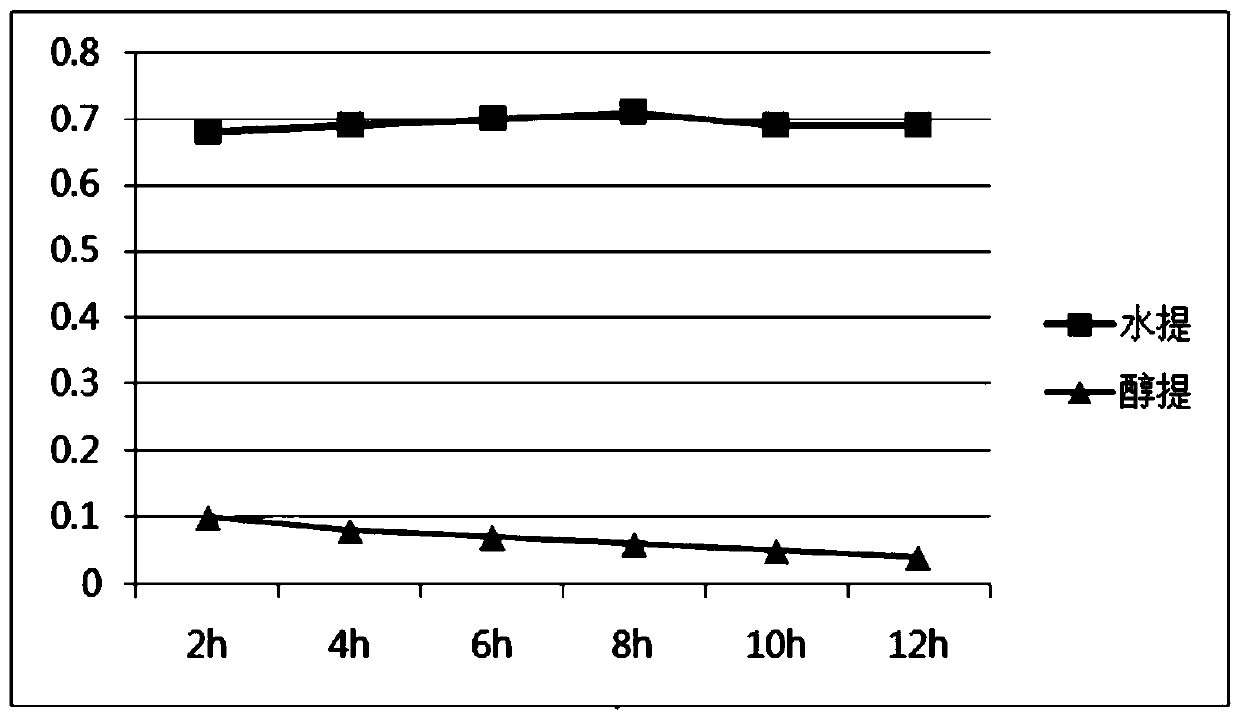

[0041] (3) In a light-proof environment, add ethanol aqueous solution to the mulberry after liquid nitrogen homogenization in step (2) for extraction, and the extraction temperature is controlled at 49° C. to obtain a mulberry extract; the ethanol aqueous solution adopts a volume concentration of 95%. ethanol, the mass ratio of ethanol addition to mulberry is 0.8:1.

[0042] (4) centrifuging the mulberry extract obtained after the step (3) is processed, and getting the supernatant;

[0043] (5) the supernatant obtained in step (4) is concentrated under reduced pressure to obtain mulberry paste;

[0044] (6) Homogenize the mulberry paste obtained in step (5) to obtain the mulberry essence.

Embodiment 2

[0046] (1) Store the ripe mulberry fresh fruit after picking in an environment of 12°C for 8 hours;

[0047] (2) carrying out liquid nitrogen homogenization with the mulberry processed in step (1);

[0048] (3) In a light-proof environment, add ethanol aqueous solution to the mulberry after liquid nitrogen homogenization in step (2) for extraction, and the extraction temperature is controlled at 48° C. to obtain a mulberry extract; the ethanol aqueous solution adopts a volume concentration of 95%. ethanol, the mass ratio of ethanol addition to mulberry is 1.1:1.

[0049] (4) Centrifuge the mulberry extract obtained after the treatment in step (3), and take the supernatant; the centrifugal speed is 3200rpm, and the centrifugation time is 20min.

[0050] (5) The supernatant obtained in step (4) is concentrated by vacuum distillation to obtain mulberry paste; the pressure of vacuum distillation concentration is lower than 10KPa, and the temperature is 49°C

[0051] (6) Homogeni...

Embodiment 3

[0053] (1) Store the ripe mulberry fresh fruit after picking under the environment of 10 ℃ for 10 hours;

[0054] (2) carrying out liquid nitrogen homogenization with the mulberry processed in step (1);

[0055] (3) In a light-proof environment, add ethanol aqueous solution to the mulberry after liquid nitrogen homogenization in step (2) for extraction, and the extraction temperature is controlled below 50° C. to obtain a mulberry extract; the ethanol aqueous solution adopts a volume concentration of 95 % ethanol, the mass ratio of ethanol addition to mulberry is 1:1.

[0056] (4) The mulberry extract obtained after the step (3) is processed is subjected to centrifugation, the centrifugal speed is 4000rpm, and the centrifugation time is 20min, and the supernatant is taken;

[0057] (5) The supernatant obtained in step (4) is concentrated by vacuum distillation, the pressure of vacuum distillation concentration is lower than 10KPa, and the temperature is 48°C; obtain mulberry ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap