Three-layer vacuum titanium cup and preparation technology thereof

A vacuum and vacuuming technology, which is applied in the field of three-layer vacuum titanium cup and its preparation technology, can solve the problems of short heat preservation time and inability to achieve vacuum heat preservation cup, etc., to increase vacuum effect, enhance vacuum heat preservation effect, and prolong vacuum heat preservation the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0021] The three-layer vacuum titanium cup of this embodiment also includes the following preparation processes:

[0022] (1) The stainless steel titanium ring at the cup mouth is welded to the stainless steel middle layer;

[0023] (2) The titanium inner tank is welded to the stainless steel titanium ring of the cup mouth;

[0024] (3) Welding at the bottom of the stainless steel middle layer;

[0025] (4) The stainless steel outer layer is welded to the stainless steel titanium ring of the cup mouth;

[0026] (5) The stainless steel outer layer is welded and evacuated outsole.

[0027] The beneficial effects of this embodiment:

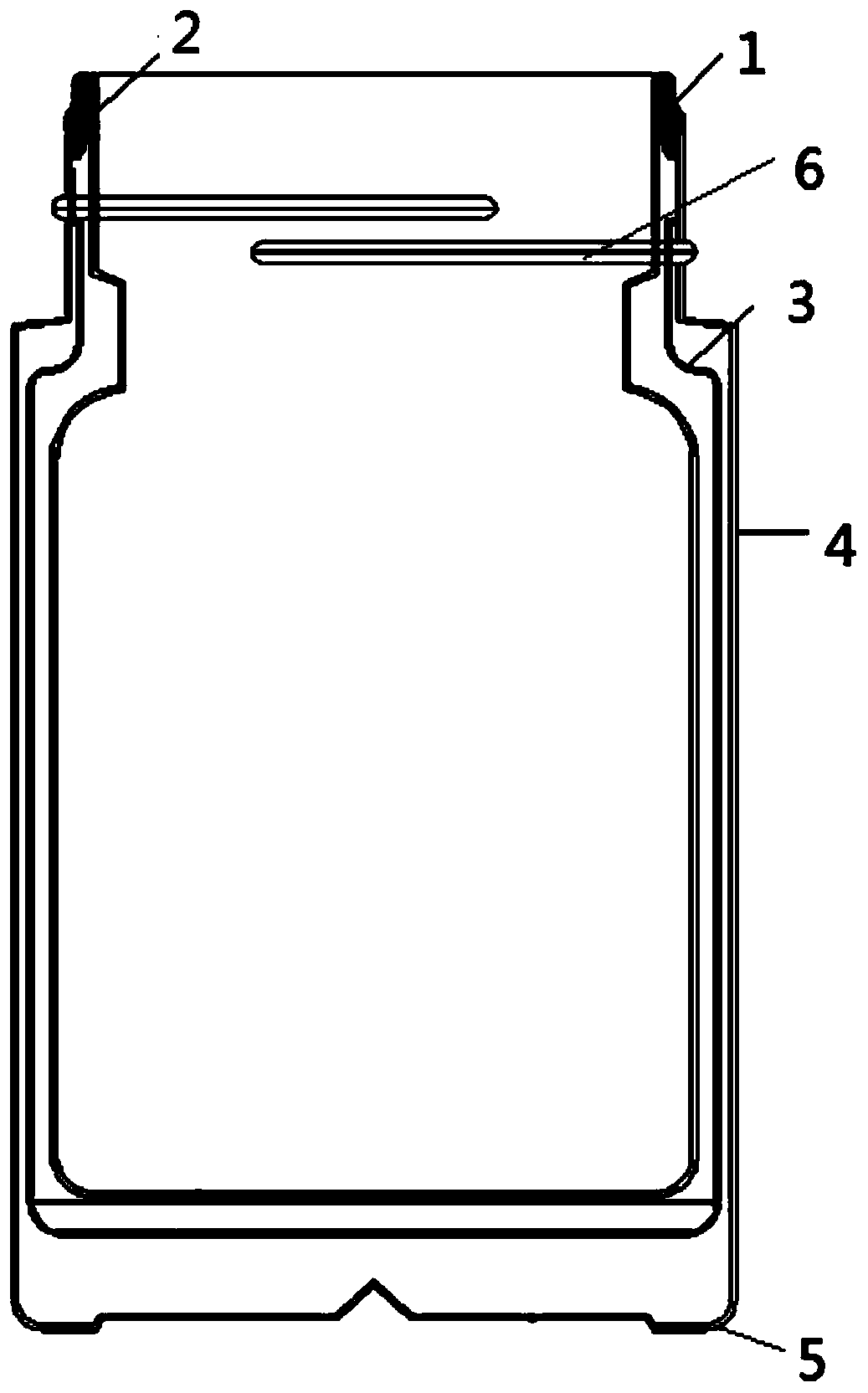

[0028] The three-layer vacuum titanium cup is composed of three separate cup bodies, a stainless steel outer layer, a stainless steel middle layer, and a titanium inner layer. The stainless steel outer layer and the stainless steel middle layer are welded to form a vacuum layer to achieve a vacuum effect; the titanium inner layer and the stainless steel middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com