Connecting load-bearing joint structure of adjustable rotary precast concrete exterior hanging wall panel and steel beam and construction method

A technology of prefabricated concrete and external hanging wall panels, which is applied in the direction of building construction, construction, and building material processing. It can solve problems such as uneven deformation of nodes and failure to meet deformation requirements, and achieve the effect of large tolerance and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

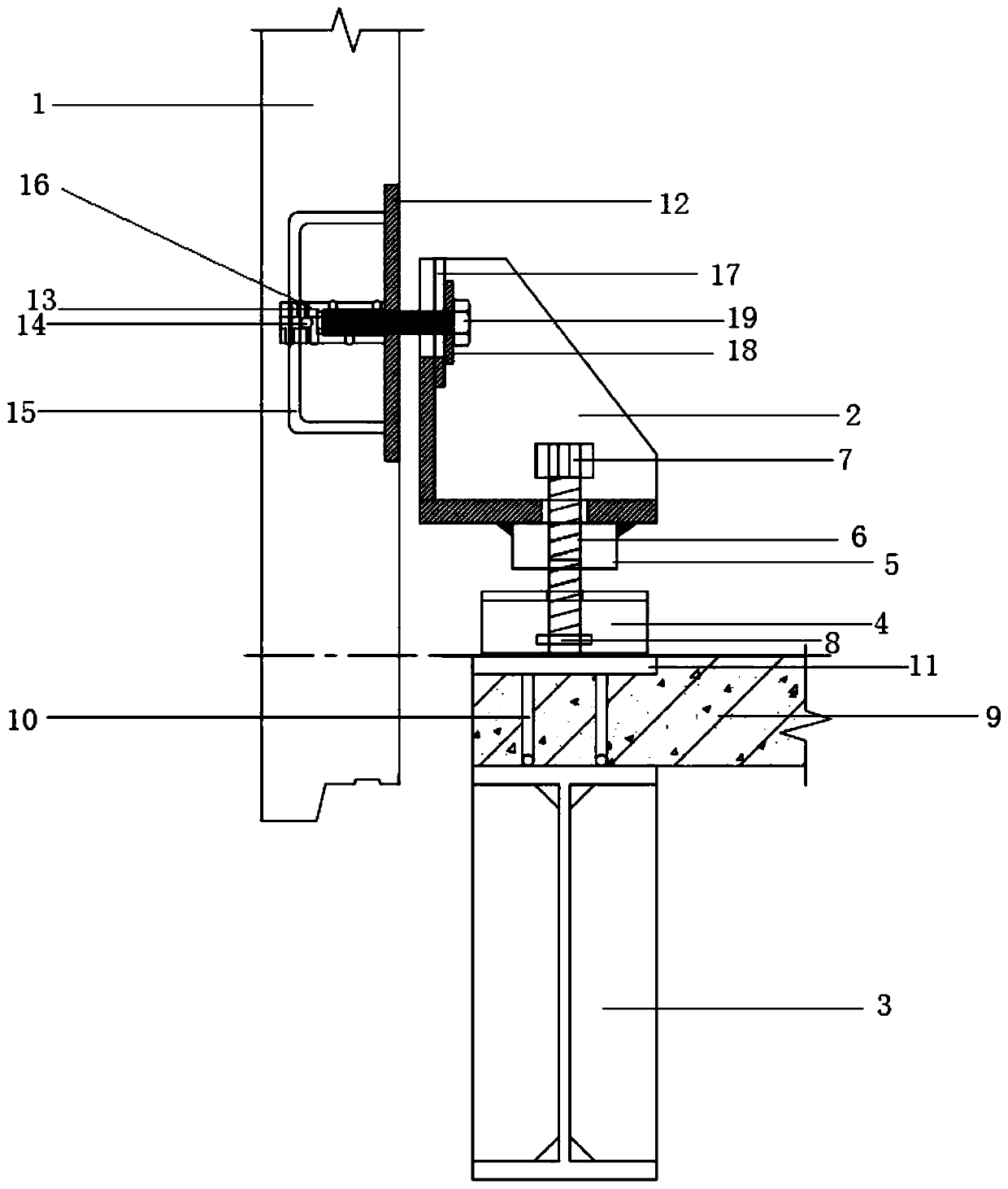

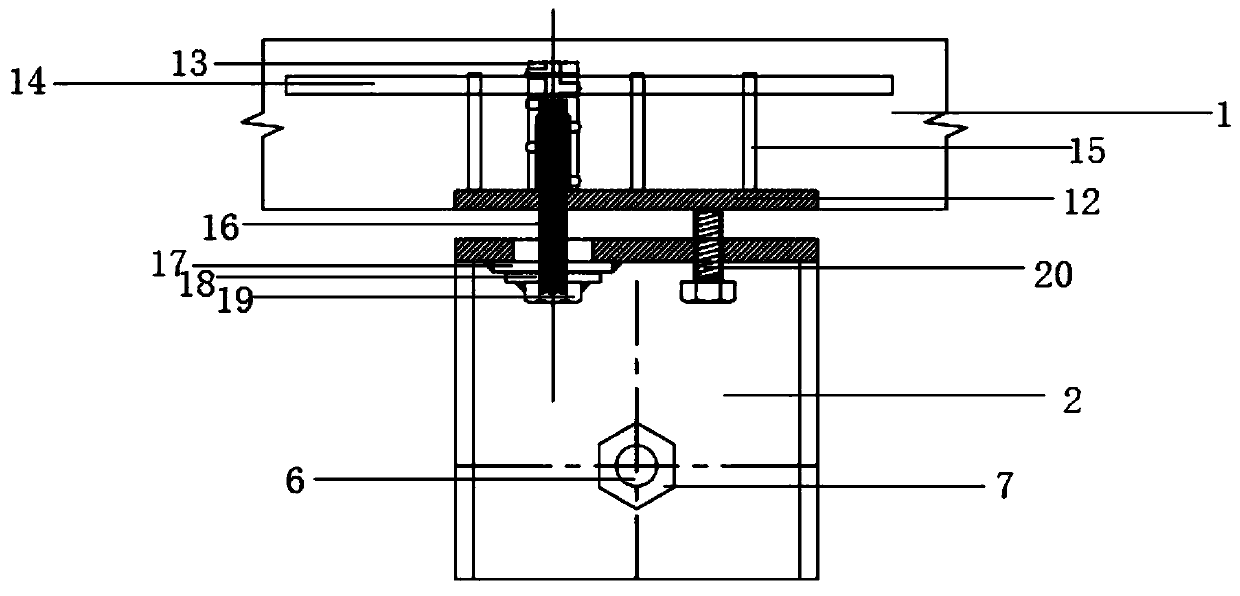

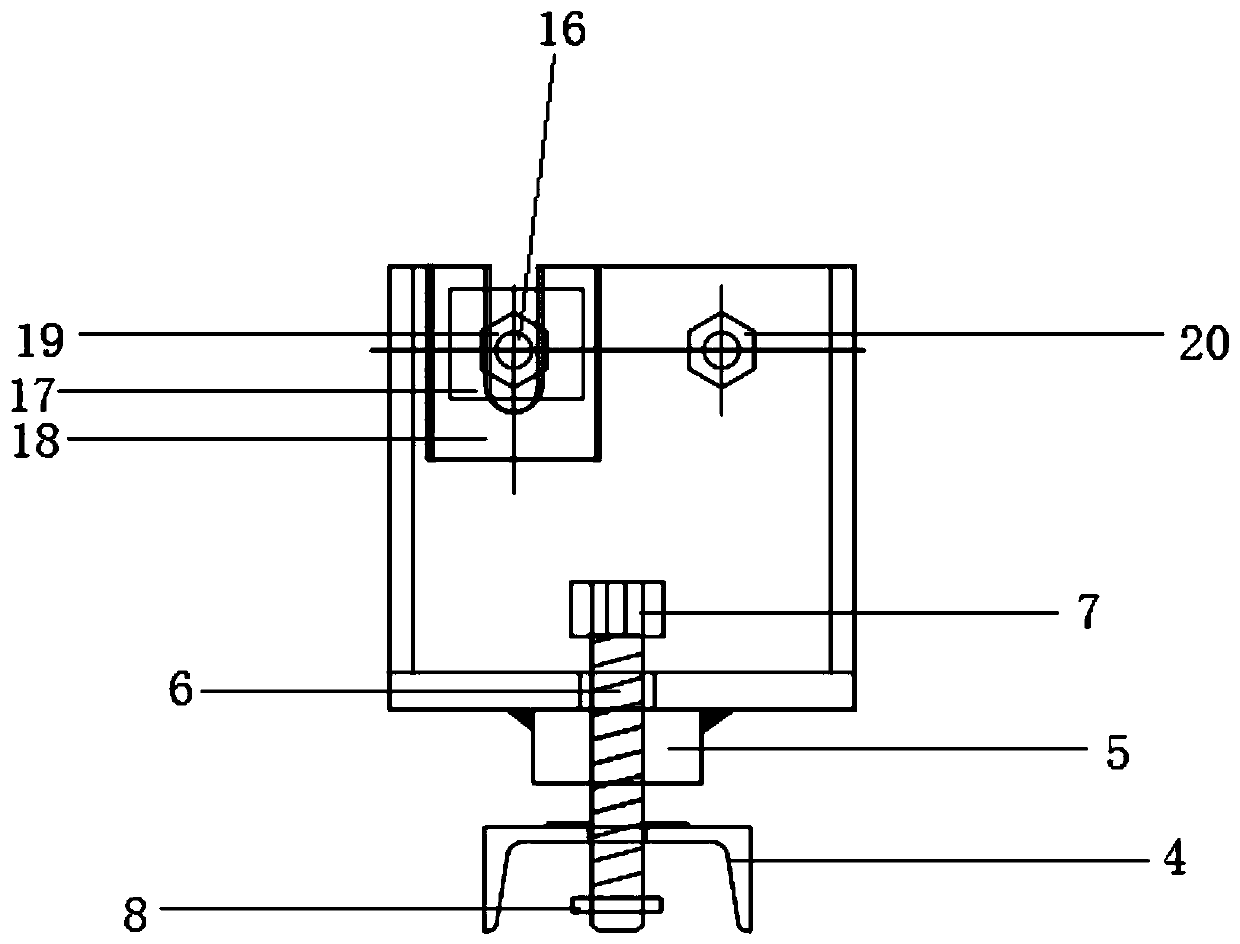

[0043] figure 2 As shown, the aforementioned steel corbel structure includes a steel corbel body, and its vertical steel plates are parallel to the precast concrete external wall panels, and U-shaped grooves and round holes are symmetrically provided on both sides of the vertical center line of the vertical steel plates and the horizontal bottom plate. A rotatable connection structure is installed in the U-shaped groove, and a horizontal positioning structure is installed in the round hole;

[0044] Install the pre-embedded steel plate in the side wall adjacent to the precast concrete external wall panel and the steel corbel structure, and the pre-embedded bolt connectors are buried in the precast concrete external wall panel, and are vertically laid with the inner side of the wall panel pre-embedded steel plate by welding ;

[0045] The two open ends of the C-shaped anchor bars are symmetrically fixed on the inner side of the pre-embedded steel plate of the wallboard by wel...

Embodiment 2

[0051] image 3 As shown in the figure, the horizontal bottom plate of the steel corbel body has a large circular hole, and a load-bearing structure is installed in it. There is a pre-embedded structure in the concrete floor slab, and the load-bearing structure is fixed with the steel beam through the pre-embedded structure;

[0052] The load-bearing structure includes connectors welded to the bottom of the steel corbel body transverse floor through fillet welds, and a round hole through the connector is opened in the connector, which is coaxially opened with the large round hole;

[0053] It also includes load-bearing bolts, and threads matching the load-bearing bolts are provided in the round holes of the connectors;

[0054] It also includes channel steel, which is fixed on the surface of the concrete floor, and a channel steel round hole is set on the flange of the channel steel. One end of the load-bearing bolt passes through the connector and the large round hole of the ...

Embodiment 3

[0060] The specific construction process of the node structure of the present application includes the following steps:

[0061] The first step: pre-construction preparation, weld the connecting piece through the fillet weld at the bottom of the horizontal bottom plate of the steel corbel body, and open a through connecting piece round hole in the connecting piece, and the connecting piece round hole is coaxial with the large round hole of the horizontal bottom plate Set up, in the round hole of the connecting piece, the thread matching the load-bearing bolt is arranged, the channel steel round hole is set in the channel steel, and the bottom of the channel steel and the floor embedded steel plate embedded in the concrete floor slab are welded and fixed by fillet welds.

[0062] On the vertical steel plate of the steel corbel body, U-shaped grooves and round holes are symmetrically set on the center line perpendicular to the horizontal bottom plate.

[0063] Embed pre-embedded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com