Elastic hinge for eyeglasses and assembling method of elastic hinge

An elastic hinge, glasses technology, applied in glasses/protective glasses, glasses/goggles, instruments, etc., can solve problems such as difficulty in disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

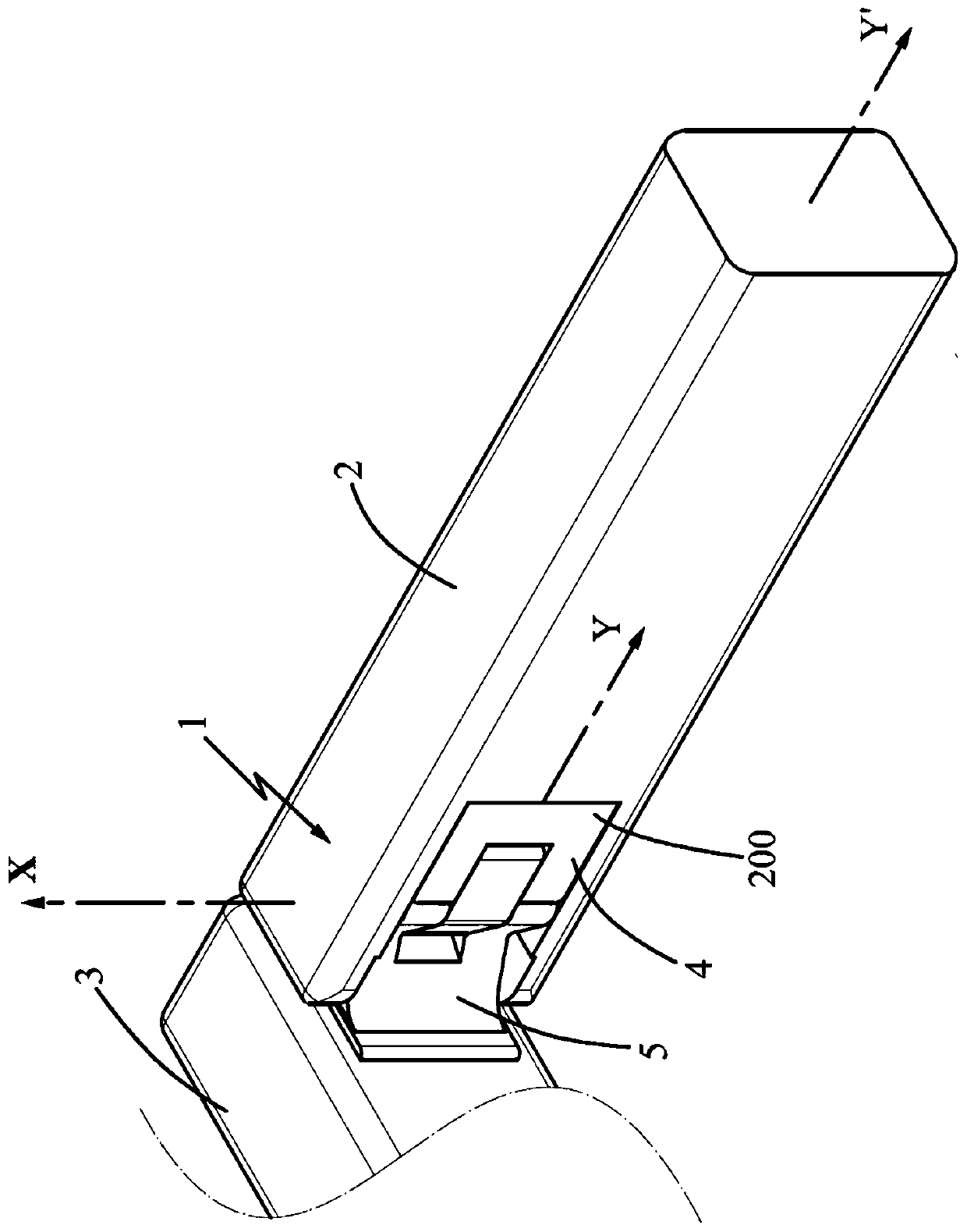

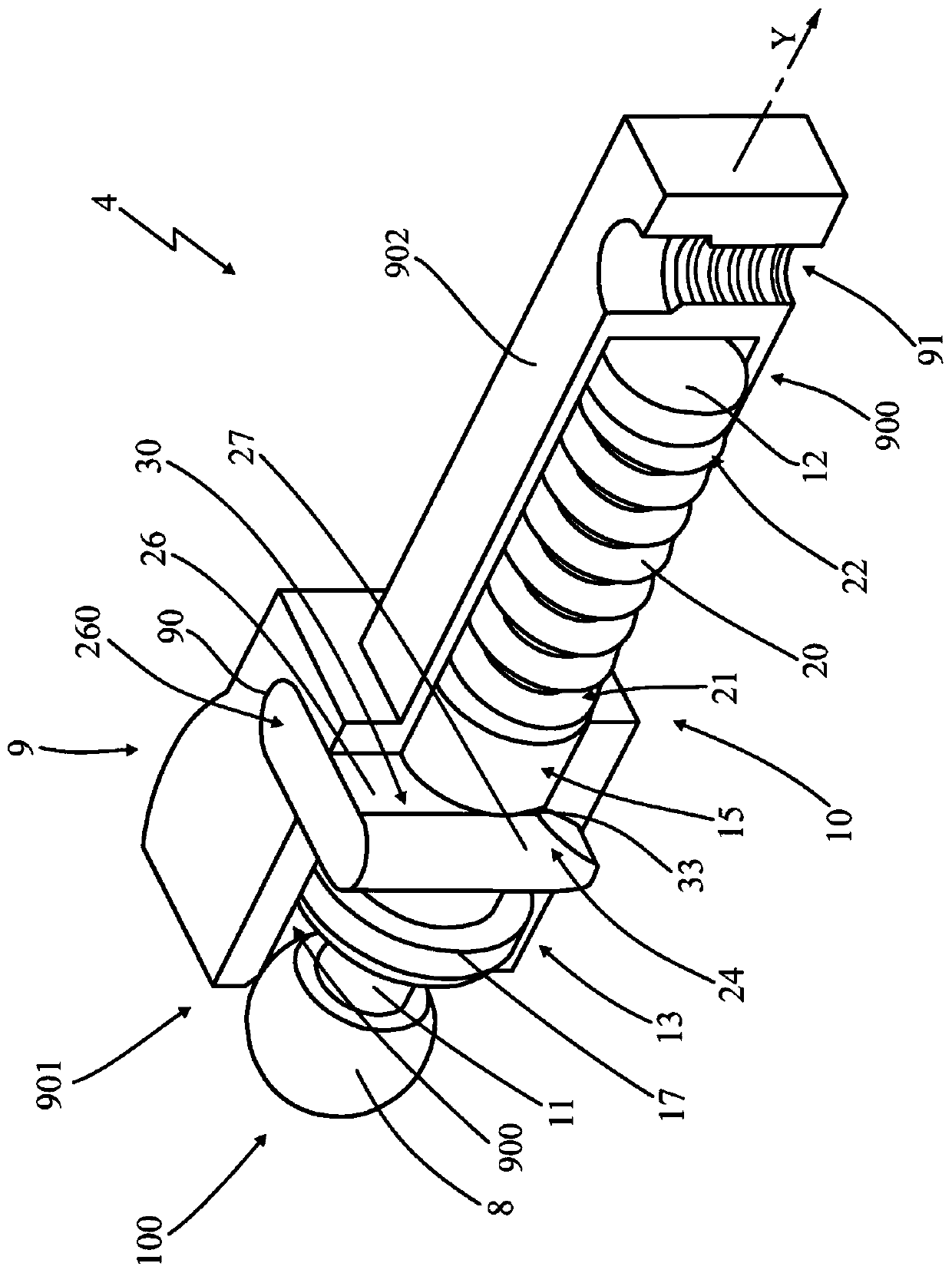

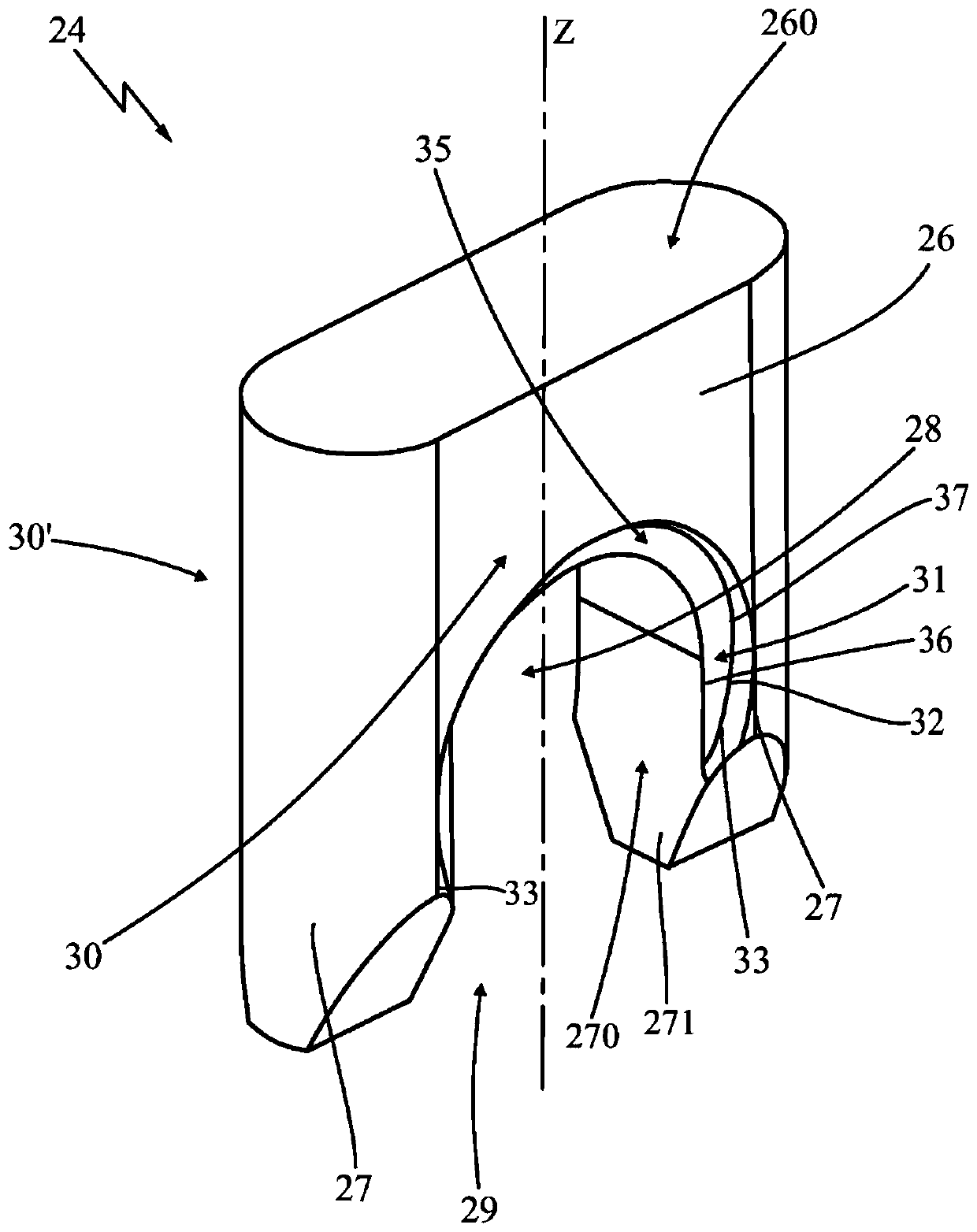

[0029] The elastic hinge 1 of the spectacle frame according to the present invention is shown as a whole with reference to the accompanying drawings.

[0030] According to the invention, the elastic hinge 1 is aimed at realizing various spectacle frames, both traditional and sporty, and is intended to be interconnected to a leg 2 corresponding to the nose 3 of the spectacle frame.

[0031] In more detail, the frame usually consists of a front for supporting a pair of lenses connected by a bridge in the middle through two annular sections (or "circles") and a pair of lenses pivotally secured to the sides of the front by elastic hinges 1 The legs 2 constitute, more precisely, the elastic hinges fastened to the two side parts towards the rear of the glasses, called noses 3 in the technical terminology of the industry.

[0032] In particular, the hinge 1 is elastic, which allows the legs 2 to open overtravel, and the elastic resilience makes the glasses comfortable to wear and ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com