Automatic jelly gel flower production equipment and working process thereof

A kind of production equipment and jelly jelly technology, which is applied in the field of automatic jelly jelly production equipment and its working process, and can solve the problems of high technical threshold, difficult management, and difficult guarantee of process quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to disclose the technical content used in the present invention, the purpose of the invention and the functions achieved more completely and clearly, a detailed description is now given.

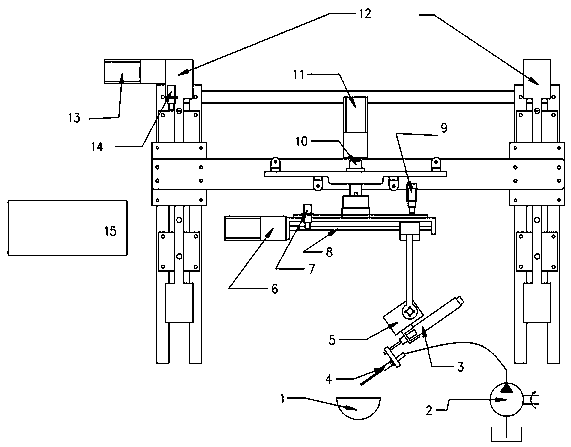

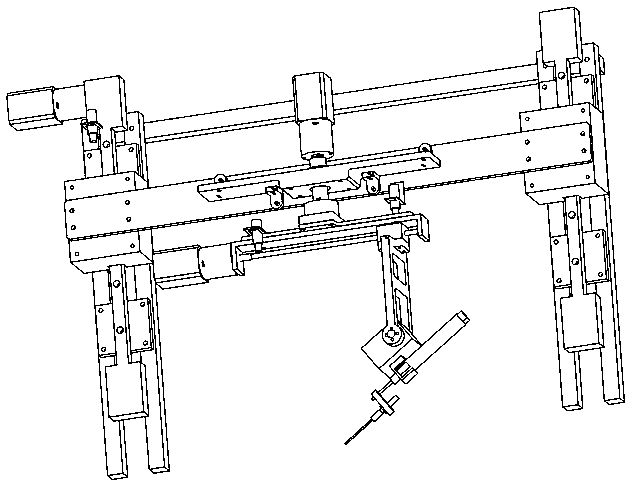

[0025] See figure 1 and figure 2 , the present invention is a preferred embodiment of an automatic jelly flower production equipment, including a human-computer interaction operation panel 15, a vertical movement mechanism, a lateral movement mechanism, a rotation mechanism, an angle steering gear 5, a jelly flower injection mechanism and a jelly flower injection mechanism. Blank 1; said vertical movement mechanism is slidably connected with said rotation mechanism, said rotation mechanism is connected with said lateral movement mechanism, said lateral movement mechanism is slidably connected with said angle steering gear 5, said angle The steering gear 5 is connected with the jelly jelly flower injection mechanism, and the jelly jelly flower injection mechanism injects the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com