Multi-steaming-chamber cooking ware and steaming box with same

A technology for cooking utensils and steaming chambers, which is applied in the field of cooking equipment and can solve the problem that a steaming box cannot steam multiple dishes at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

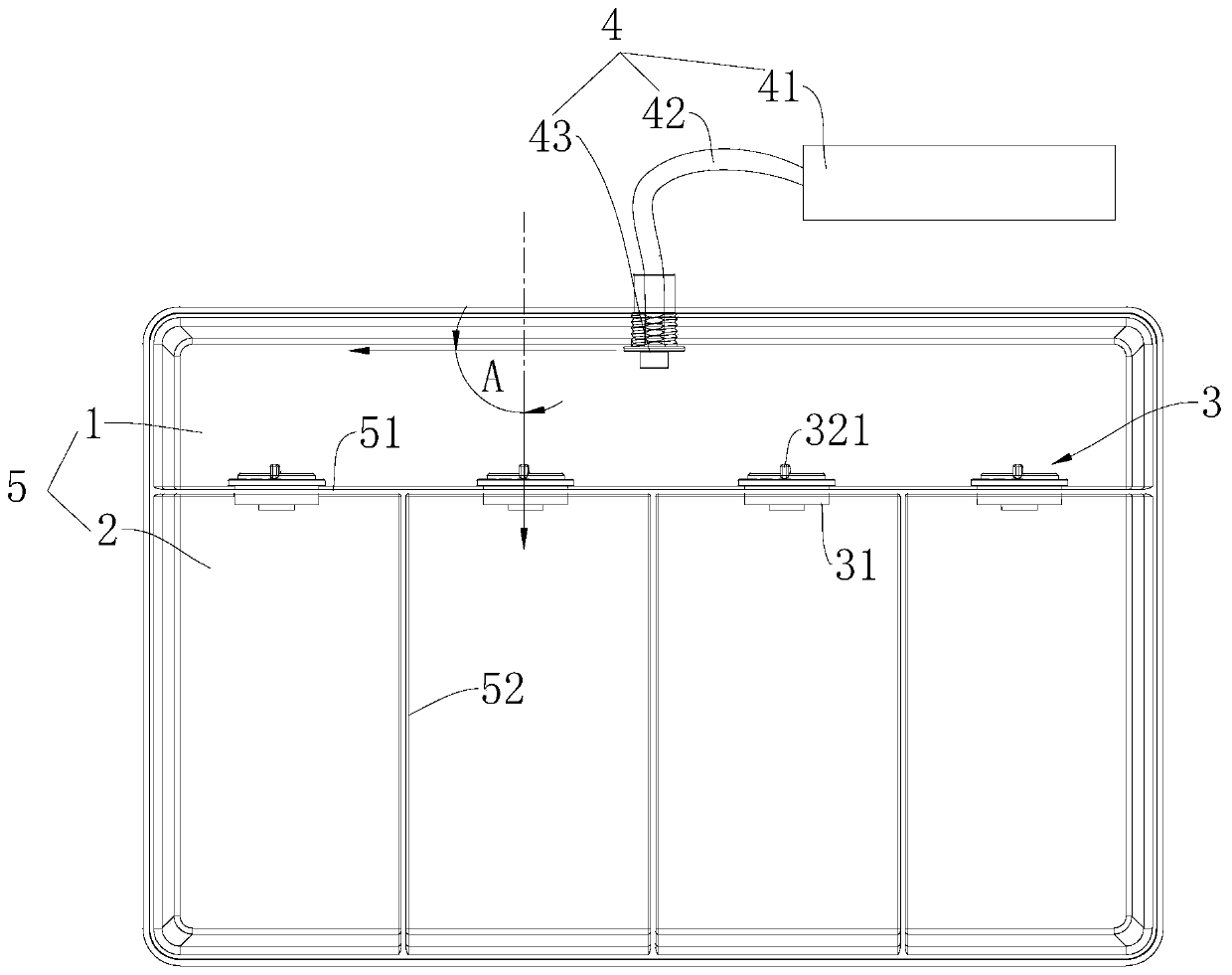

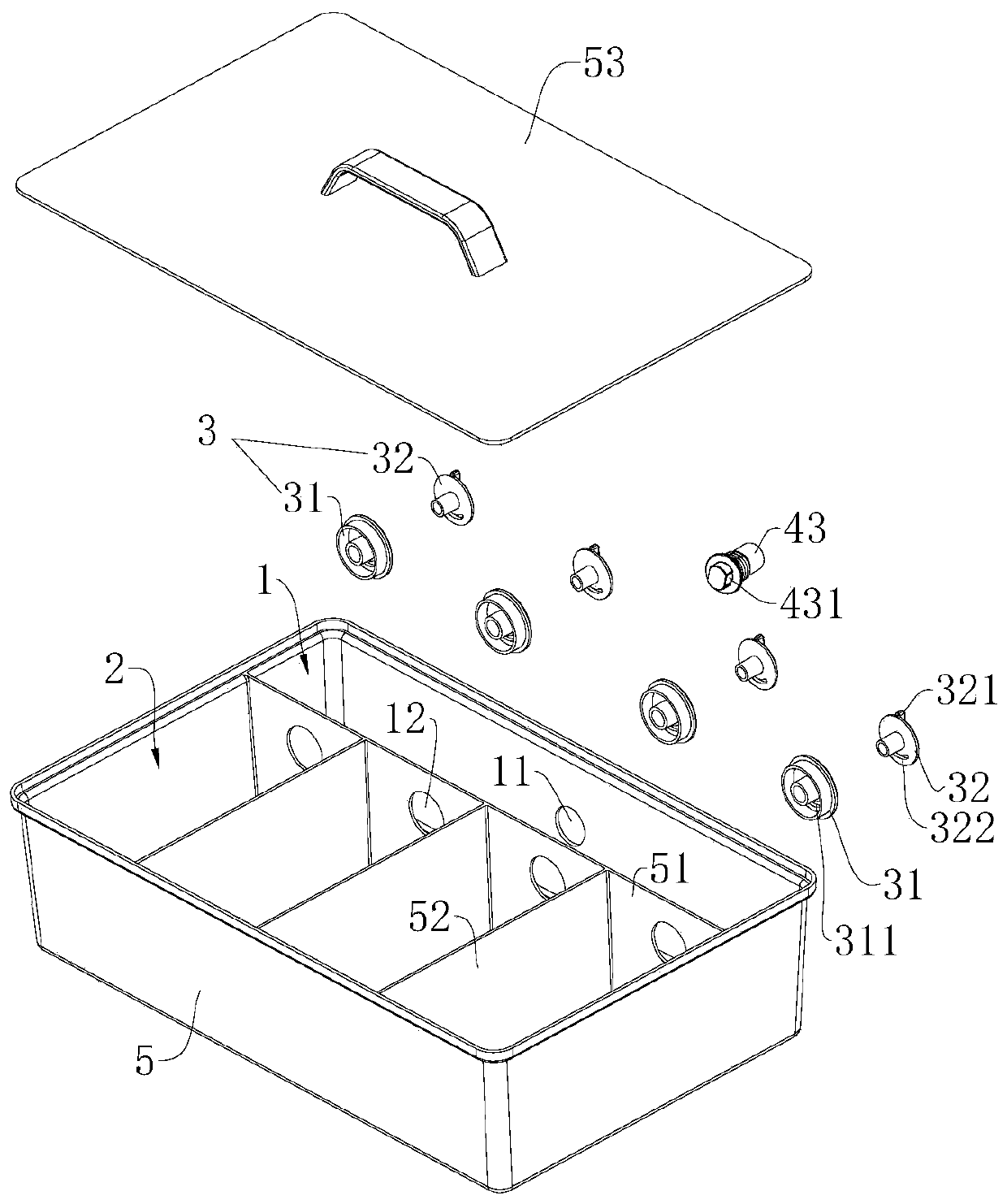

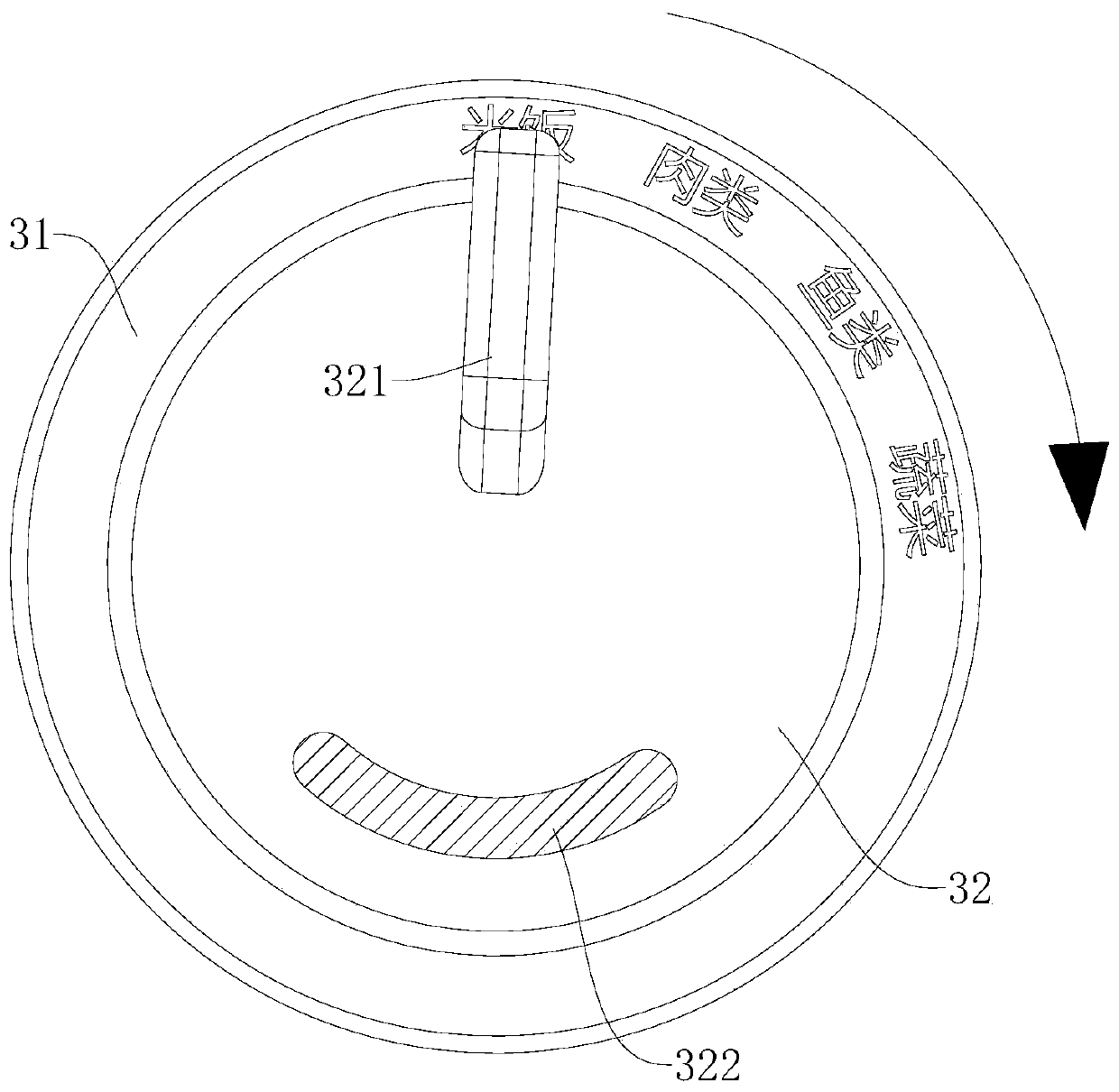

[0062] This embodiment provides a cooking vessel with multiple steam chambers, including: a steam generating assembly 4, which provides steam for steam cooking; also includes: a gas distribution chamber 1, including an air inlet 11 for communicating with the steam generating assembly 4; at least two Each compartment steam room includes a gas distribution port 12 for communicating with the gas distribution chamber 1. The steam generated by the steam generating component 4 enters the gas distribution chamber 1 and remains in the gas distribution chamber 1 . The steam in the distributing chamber 1 enters the steaming chambers of different compartments respectively through the distributing port 12 . Multiple steaming chambers can place various ingredients and steam them at the same time.

[0063] There is no specific limitation on the number of gas distribution chambers 1 , and in this embodiment, there are four gas distribution chambers 1 . As an alternative embodiment, there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com