LED wall washer

A technology of LED wall washer and LED light source, which is applied to the damage prevention measures of lighting devices, cooling/heating devices of lighting devices, lighting and heating equipment, etc. To achieve the effect of uniform and soft light output, novel light distribution method and ideal heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

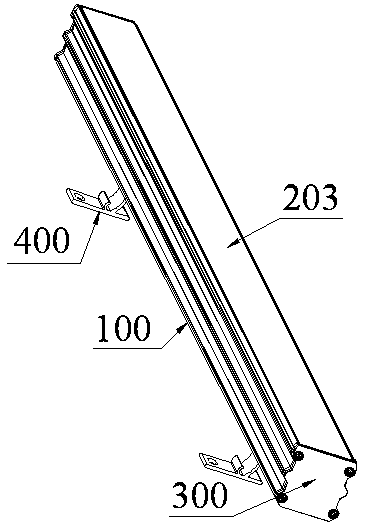

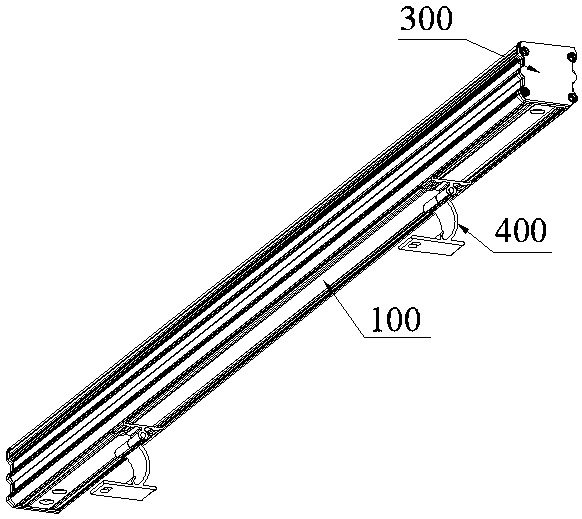

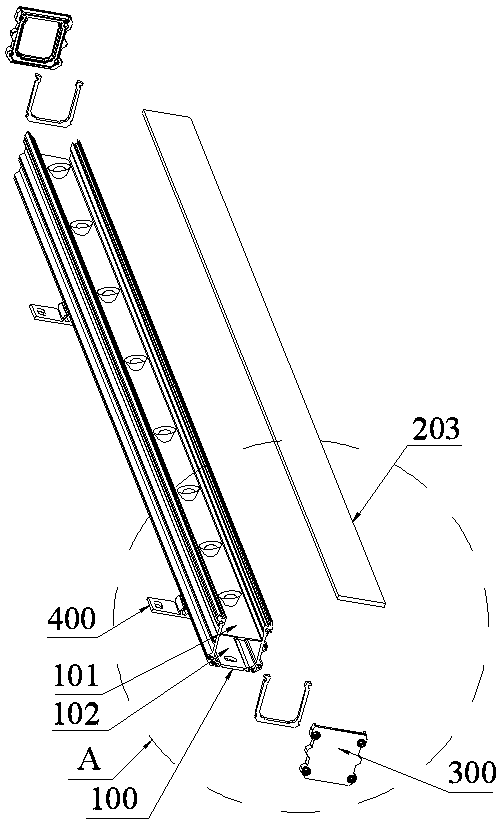

[0014] refer to Figure 1 to Figure 4 , propose an embodiment of an LED wall washer of the present invention, including a heat dissipation lamp housing 100, several LED light sources disposed in the heat dissipation lamp housing 100, and a driver electrically connected to the LED light source located in the heat dissipation lamp housing 100 The device, the light guide and translucent cover 203 installed on the heat dissipation lamp housing 100 to guide and transmit light, the end cover 300 fixed on the end surface of the heat dissipation lamp housing 100 by means of snap-fitting and screwing, is installed on the heat dissipation lamp Mounting bracket 400 at the bottom of case 100 . There is a partition 101 in the middle of the heat dissipation lamp housing 100. The upper end of the partition 101 is a light source cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com