Multi-beam synthetic laser device capable of achieving flexible control

A laser device and multi-beam technology, which is applied in the field of lasers, can solve the problems that the output power of the laser affects the stability of the laser, and achieve the effect of flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

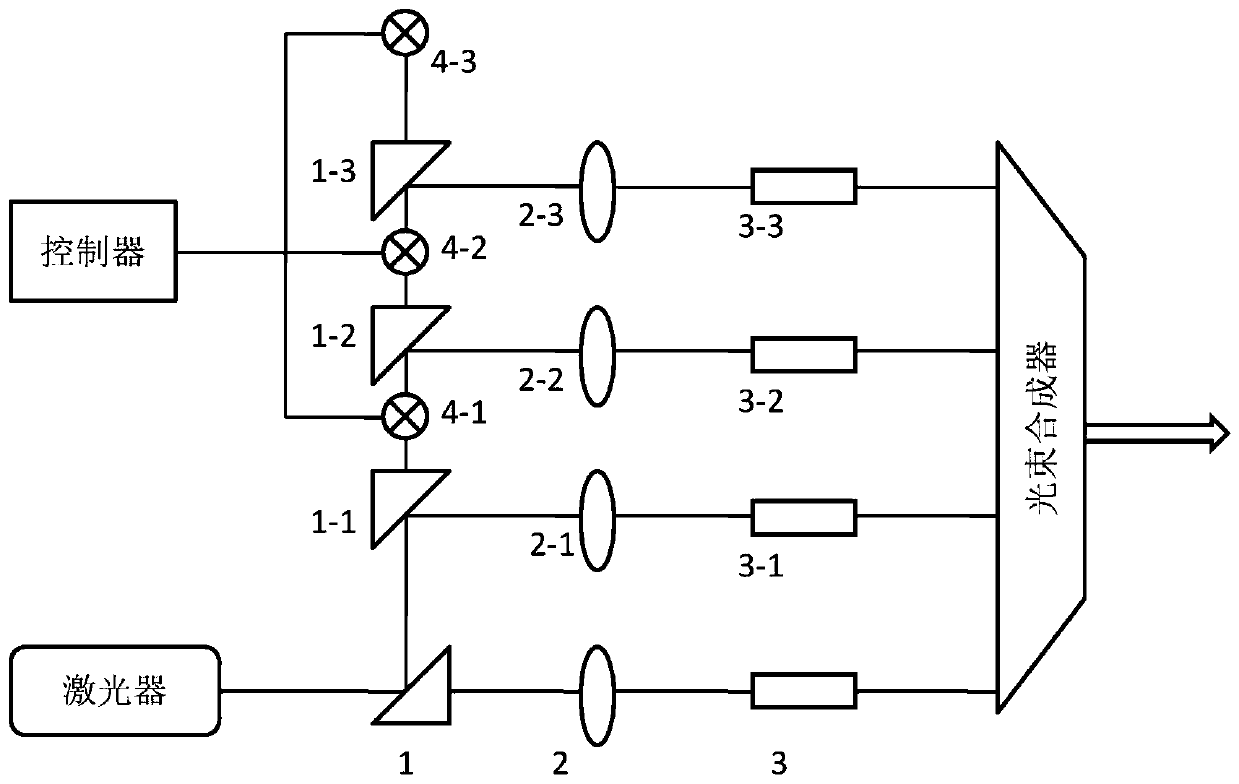

[0023] A flexibly controllable multi-beam combining laser device, comprising a laser, a main beam splitting prism 1, a first beam splitting prism 1-1, a second beam splitting prism 1-2, a third beam splitting prism 1-3, and a first beam baffle 4 -1, the second beam baffle 4-2, the third beam baffle 4-3, the main lens 2, the first lens 2-1, the second lens 2-2, the third lens 2-3, the main optical fiber 3, A first optical fiber 3-1, a second optical fiber 3-2, a third optical fiber 3-3, and a beam combiner.

[0024] Further, the laser radiates a main laser beam, and the main laser beam is split into a main transmitted beam and a main reflected beam after passing through the main beam splitting prism; after the main reflected beam is incident on the first beam splitting prism, the beam is split into a first transmitted beam and a second beam. A reflected light beam; the first reflected light beam is incident on the first optical fiber after being focused by the first lens; Two ...

specific Embodiment 2

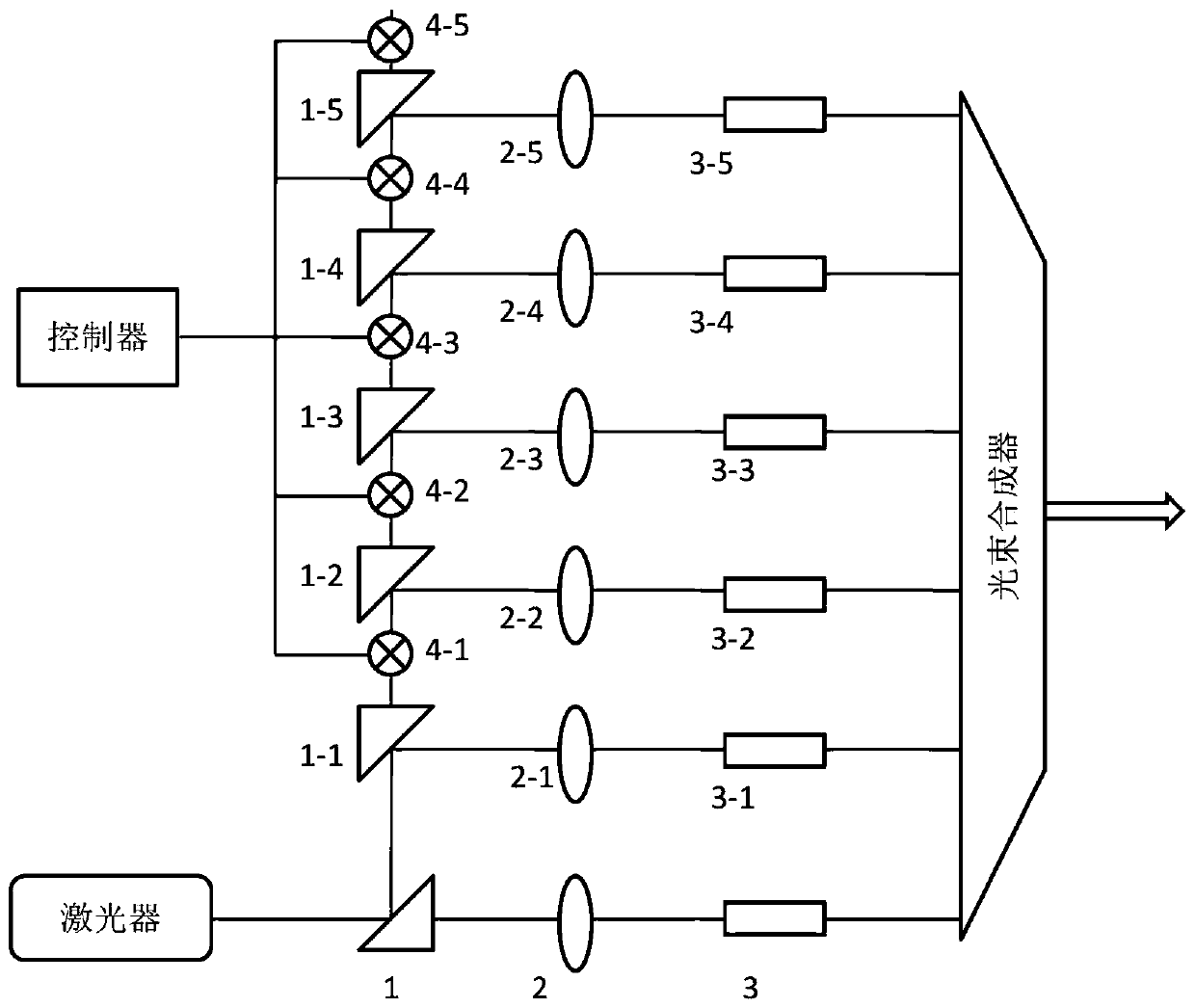

[0034] A flexibly controllable multi-beam combining laser device, comprising a laser, a main beam splitting prism 1, a first beam splitting prism 1-1, a second beam splitting prism 1-2, a third beam splitting prism 1-3, and a fourth beam splitting prism 1- 4. The fifth beam splitting prism 1-5, the first beam baffle 4-1, the second beam baffle 4-2, the third beam baffle 4-3, the fourth beam baffle 4-4, the fifth beam baffle Board 4-5, main lens 2, first lens 2-1, second lens 2-2, third lens 2-3, fourth lens 2-4, fifth lens 2-5, main optical fiber 3, first Optical fiber 3-1, second optical fiber 3-2, third optical fiber 3-3, fourth optical fiber 3-4, fifth optical fiber 3-5, beam combiner.

[0035]Further, the laser radiates a main laser beam, and the main laser beam is split into a main transmitted beam and a main reflected beam after passing through the main beam splitting prism; after the main reflected beam is incident on the first beam splitting prism, the beam is split in...

specific Embodiment 3

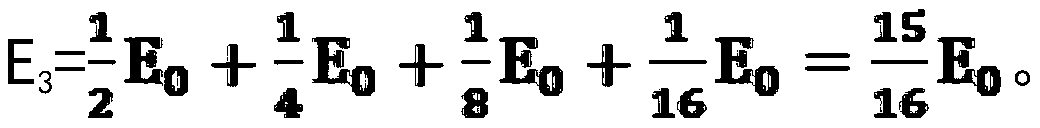

[0045] A flexibly controllable multi-beam synthesis laser device, including a laser, a main beam splitting prism, a first beam splitting prism, a second beam splitting prism, ... nth beam splitting prism, a first beam baffle, a second beam baffle, ... The nth beam baffle, the main lens, the first lens, the second lens, ... the nth lens, the main optical fiber, the first optical fiber, the second optical fiber, ... the nth optical fiber, and a beam combiner. Wherein, n is a positive integer, preferably greater than or equal to 2.

[0046] Further, the laser radiates a main laser beam, and the main laser beam is split into a main transmitted beam and a main reflected beam after passing through the main beam splitting prism; after the main reflected beam is incident on the first beam splitting prism, the beam is split into a first transmitted beam and a second beam. A reflected light beam; the first reflected light beam is incident on the first optical fiber after being focused b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com