An adjustable check valve, an automobile engine cooling system and an automobile

A technology of check valve and valve body, which is applied in the direction of engine cooling, engine components, machine/engine, etc. It can solve the problems of sealing ring or rubber aging, check valve valve easy to enter impurities, spring fluid pressure strength is not sensitive enough, etc. , to achieve the effect of improving power performance and heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

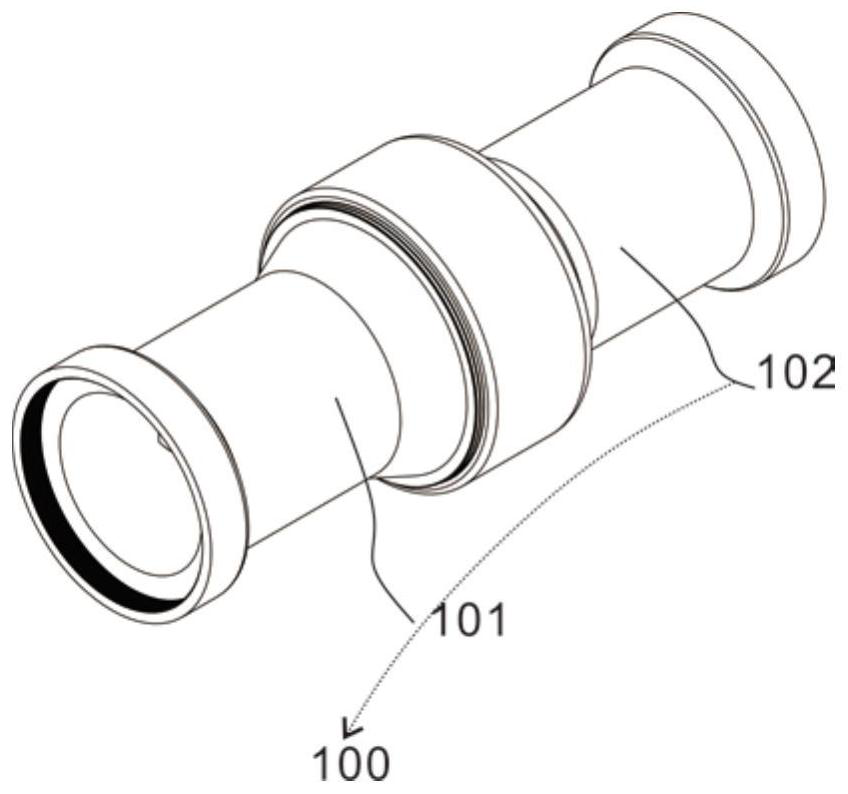

[0035] refer to figure 1 As an embodiment of the present invention, the adjustable check valve includes a valve body 100 and a valve core 200 .

[0036] Among them, the valve body 100 includes a first valve assembly 101 and a second valve assembly 102, each of which forms a fluid chamber inside; the valve core 200, the valve core 200 includes a valve disc 201 and a swing assembly 202, and the swing assembly 202 drives the valve clack 201 Qihe.

[0037] Specifically, the valve body 100 is a flange-like pipe structure, which divides the first valve assembly 101 and the second valve assembly 102 , and the two are fixed by welding or integral casting to form the valve body 100 . Both ends of the valve body 100 are provided with standard internal threads for connecting with external components, a liquid chamber is formed inside it, and a valve flap 201 is provided in the middle of the fluid chamber.

[0038] The valve flap 201 includes a fixed piece 201a and a rotating piece 201b...

Embodiment 2

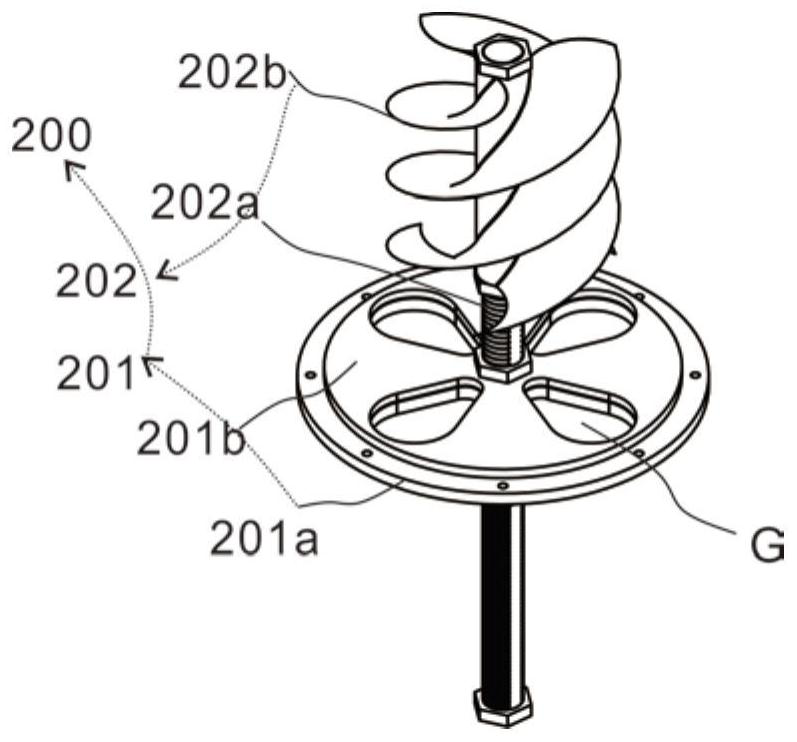

[0043] refer to figure 2 As an embodiment of the present invention, the adjustable check valve includes a valve body 100 and a valve core 200 . Among them, the valve body 100 includes a first valve assembly 101 and a second valve assembly 102, each of which forms a fluid chamber inside; the valve core 200, the valve core 200 includes a valve disc 201 and a swing assembly 202, and the swing assembly 202 drives the valve clack 201 Qihe. The adjustable check valve is different from Embodiment 1 in that: the adjustable check valve also includes an adjustment assembly 300, which is arranged on the rotating shaft 202a and can select different axial fixed positions on the rotating shaft 202a.

[0044] The adjustment assembly 300 is used to assist in adjusting the axial position of the vane 202b on the rotating shaft 202a, so that the distance between the vane 202b and the fluid input port can be adjusted, so as to adapt to different fluid intensities and increase the sensitivity of...

Embodiment 3

[0051] refer to figure 2 As an embodiment of the present invention, the adjustable check valve includes a valve body 100 and a valve core 200 . Among them, the valve body 100 includes a first valve assembly 101 and a second valve assembly 102, each of which forms a fluid chamber inside; the valve core 200, the valve core 200 includes a valve disc 201 and a swing assembly 202, and the swing assembly 202 drives the valve clack 201 Qihe. The difference between the adjustable check valve and the second embodiment is that the first valve assembly 101 and the second valve assembly 102 are connected by internal and external threads, and an intermediate cavity Z is formed inside the connecting part.

[0052] Specifically, both the first valve assembly 101 and the second valve assembly 102 are flange-like parts, and at the joint end where the first valve assembly 101 and the second valve assembly 102 are connected, they are provided with external threads; the corresponding second val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com