Check valve

A one-flow valve, valve body technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

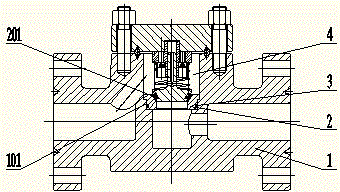

[0009] as attached figure 1 As shown, the valve seat 2 is an annular body structure, and there is a fanle sealing surface 201 at the junction of the inner hole and the upper end of the valve seat 2; the lower end of the valve cavity 4 in the valve body 1 is provided with an annular step 101, and the annular The outer cylindrical surface is clearance-fitted in the inner cylindrical surface of the annular step 101, and a sealing ring 3 is provided on the matching surface, and the other structures are the same as those of the traditional check valve.

[0010] When processing the valve body 1, it is only necessary to process the annular step 101 in the valve body 1 in one clamping; when processing the valve seat 2, since the valve seat 2 has a simple annular structure shape, rough machining, spray welding, and finishing When processing and grinding the valve sealing surface 201, its clamping is convenient and the processing technology is extremely simple; finally, an assembled str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com