Mechanical equipment fault intelligent early warning method based on multivariate estimation and prediction

A mechanical equipment and multi-variable technology, which is applied in the direction of prediction, calculation, and instrumentation, can solve problems such as abnormal fault detection of mechanical equipment under changing working conditions, avoid abnormal shutdown and major economic losses, and realize early prediction and discovery. The effect of high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further described below in conjunction with accompanying drawing:

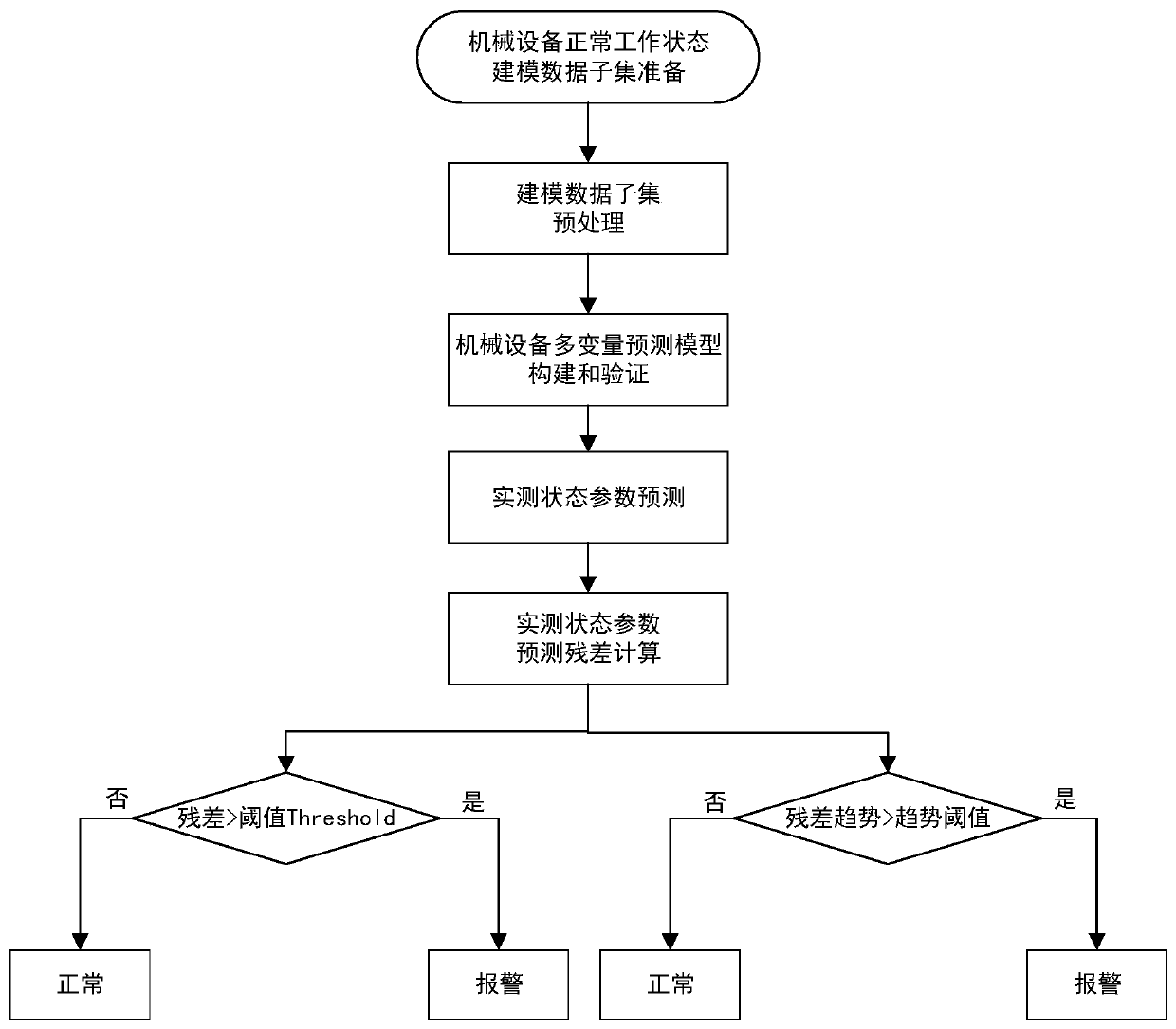

[0043] see Figure 1 to Figure 4 , an intelligent early warning method for mechanical equipment faults based on multivariate estimation and prediction, including the following steps:

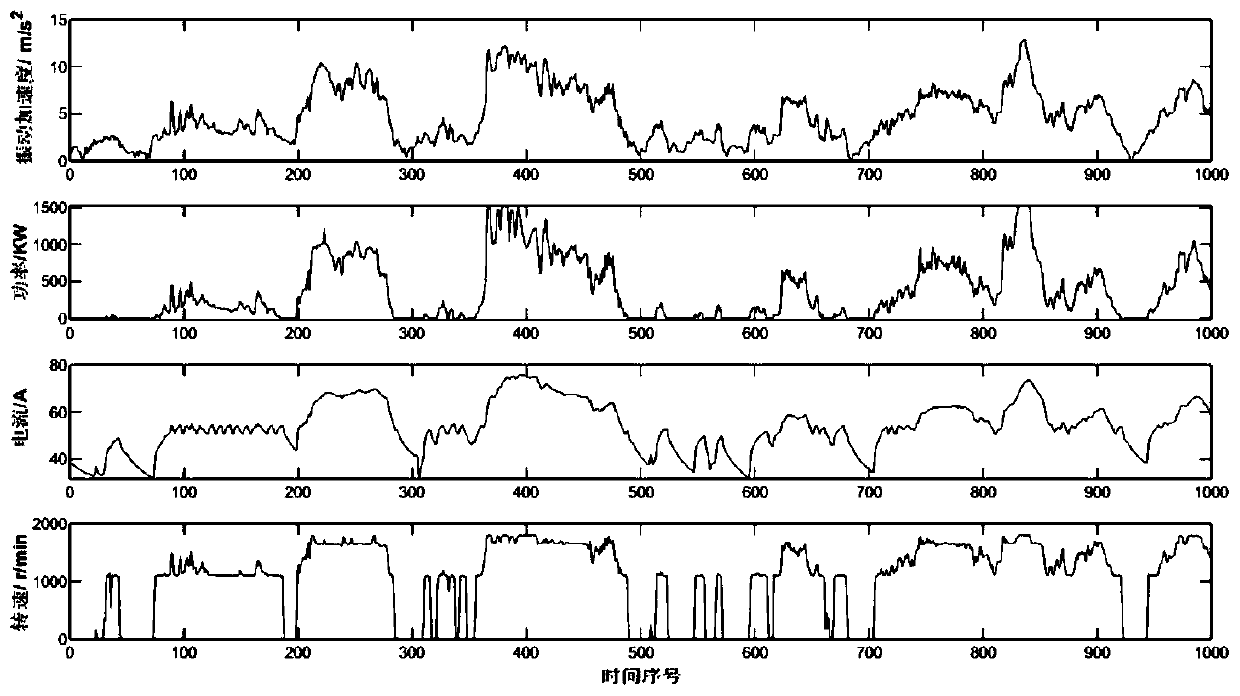

[0044] Step 1, select the state parameters of the mechanical equipment under the normal working state of the mechanical equipment and the corresponding part of the working condition data of the mechanical equipment, and model the data subset;

[0045] Step 2, preprocessing the modeling data subset: perform min-max standardization on each variable feature of the modeling data subset, and normalize to [0,1] interval;

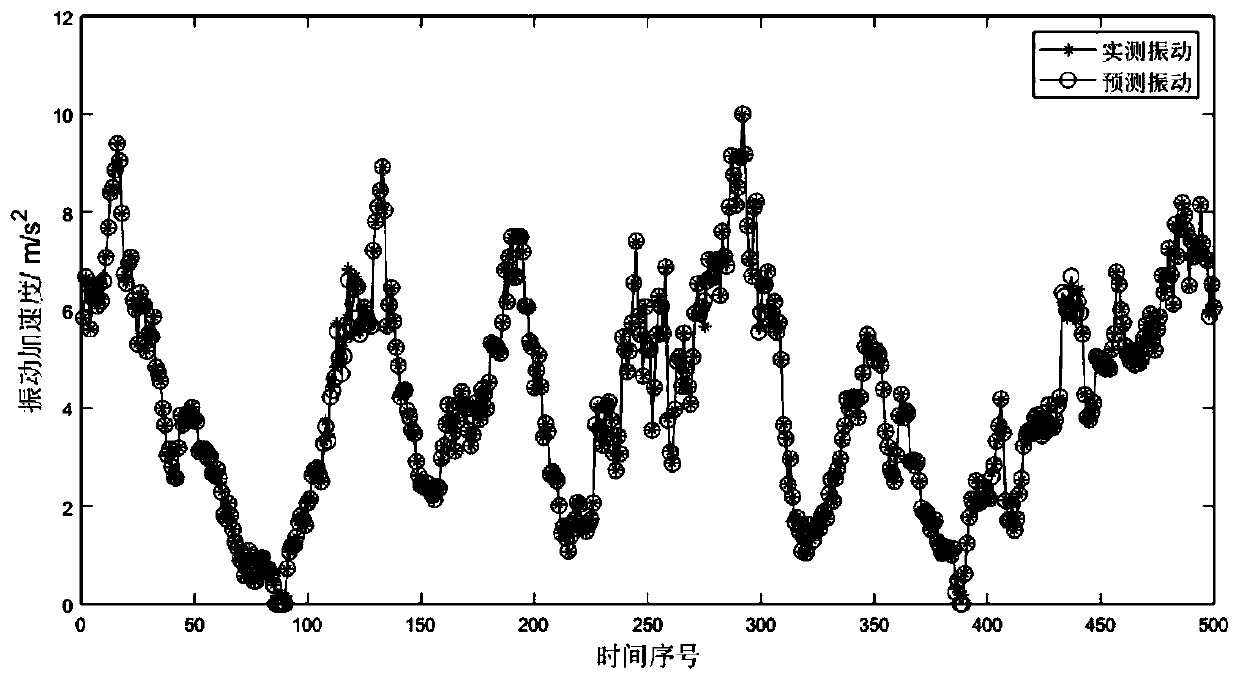

[0046] Step 3, construct the prediction model of mechanical equipment state parameters and working condition parameters: select the normalized modeling training data set to establish the corresponding normal operation space matrix D;

[0047] Step 4, the measured state parameters co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com