Device assembled with transmission shaft with self-destruct function

A transmission shaft and function technology, which is applied in the field of assembling a transmission shaft with a self-destruct function, can solve problems such as the service life of the transmission shaft cannot reach the predetermined time, the transmission shaft is strained, and the transmission shaft is broken, so as to achieve positioning reliability The effect of no movement, avoiding strain, and convenient flat groove width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

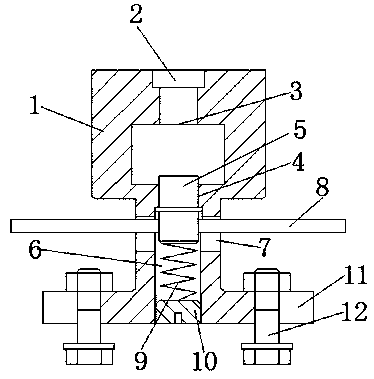

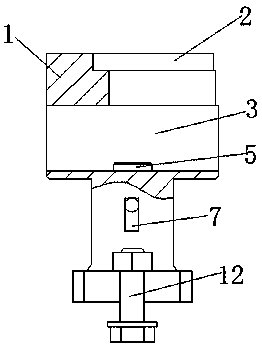

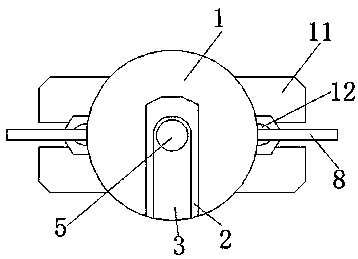

[0025] Example. A device equipped with a transmission shaft with a self-destruct function, consisting of Figure 1~3 As shown, a fixed seat 1 is included, a flat groove 2 is arranged on the top surface of the fixed seat 1, and a part groove 3 is arranged below the flat groove 2. Can refer to for better explanation principle of the present invention Figure 5 ~ Figure 7 , Figure 5 ~ Figure 7 It is a schematic diagram of the size of the structure of the present invention and the labeling of the working surface. In this embodiment, the groove width of the flat groove 2 is C, the depth is H, the groove width is C greater than the width of the flat on the shaft, and the depth H is greater than the height of the flat on the shaft, and is used to install the flat surface on the shaft parts; Part slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com