Production equipment of paper handles

A production equipment and paper technology, which is applied in the manufacture of papermaking, paper/cardboard containers, rigid/semi-rigid containers, etc., can solve the problems of low portable load-bearing capacity, low production efficiency, hand restraint, etc., and improve the portable load-bearing capacity. , Improve production efficiency and ensure the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

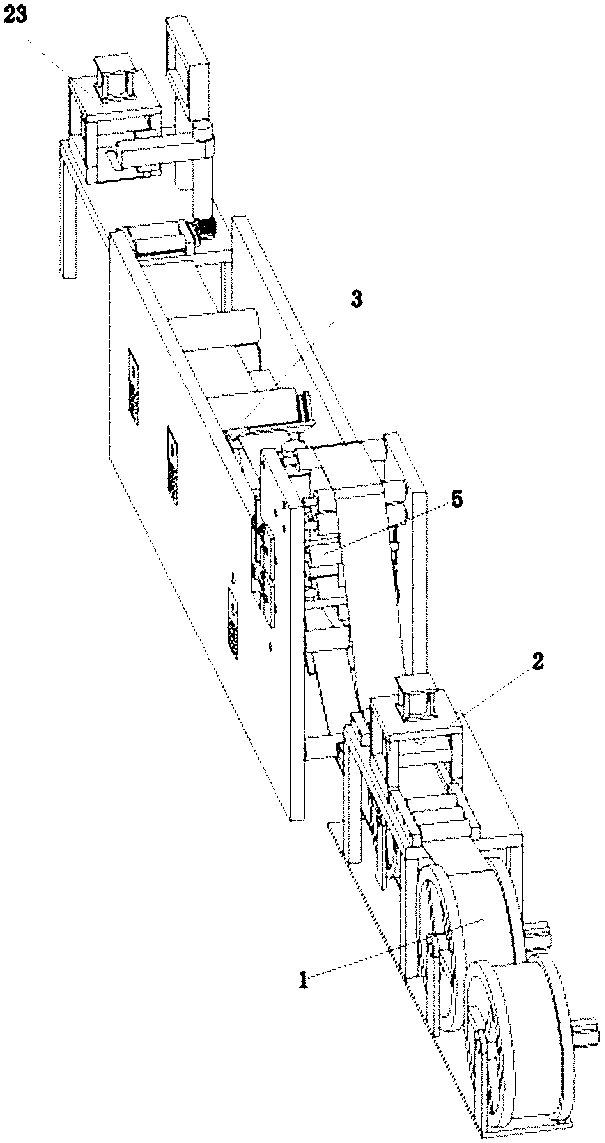

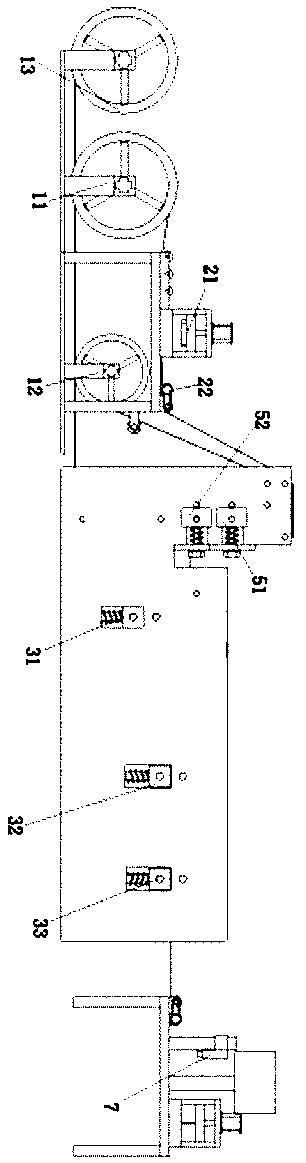

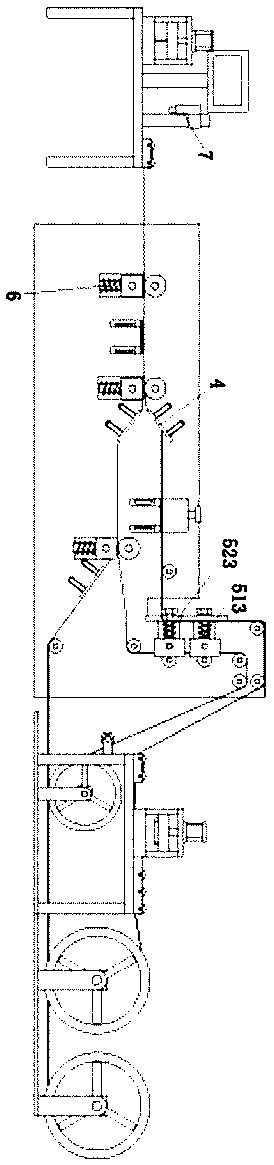

[0026] refer to Figure 1 to Figure 8 The production equipment for a paper handle shown includes a feeding device 1 for conveying paper materials, a hole cutting device 2 for cutting holes in face paper 8, a compound device for compounding paper materials and a control The feeding device 1 includes a first feeding assembly 11 for conveying face paper 8 , a second feeding assembly 12 for conveying portable paper 9 and a third feeding assembly for conveying bottom paper 10 13. The hole cutting device 2 includes a hole cutting assembly 21 for cutting holes on the hand-held paper material 9 and a driving assembly 22 for driving the paper 8 to be stably transported after the hole is cut. The gluing mechanism 4 for gluing and the composite mechanism 3 for compounding paper materials together, the feeding device 1, the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com