A pipeline non-destructive testing method and system adaptable to different areas

A technology suitable for different and non-destructive testing, applied in measuring devices, instruments, analysis of solids using sonic/ultrasonic/infrasonic waves, etc., can solve the problem of limited pipeline area, achieve the effect of simple and convenient operation and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

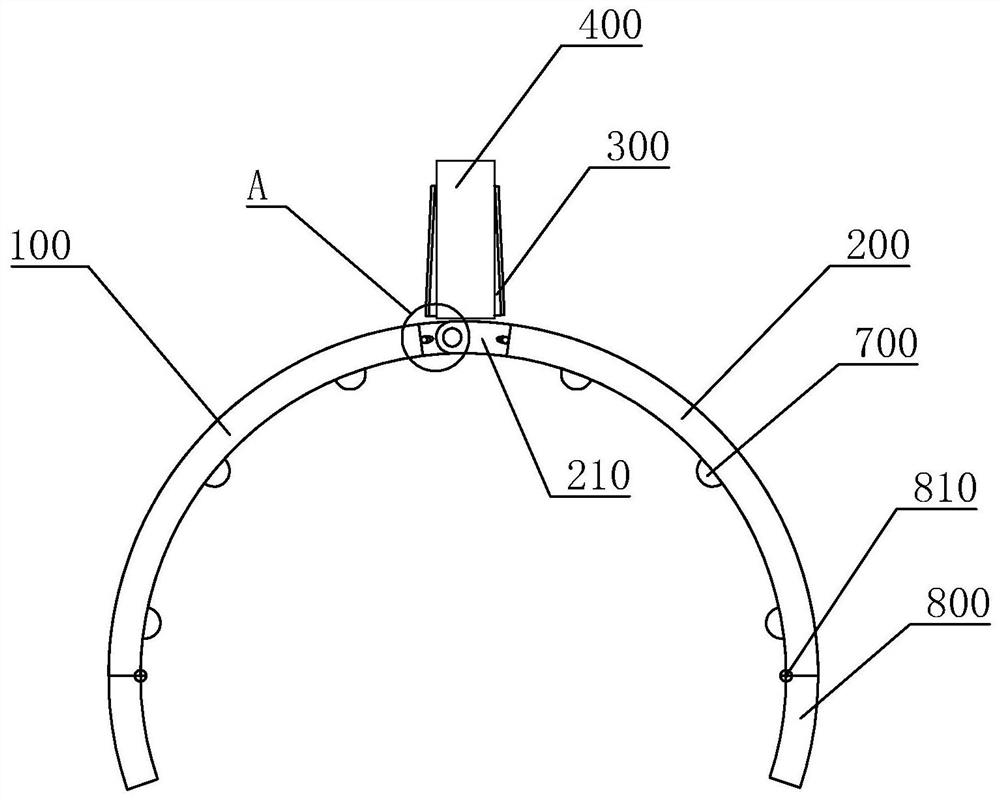

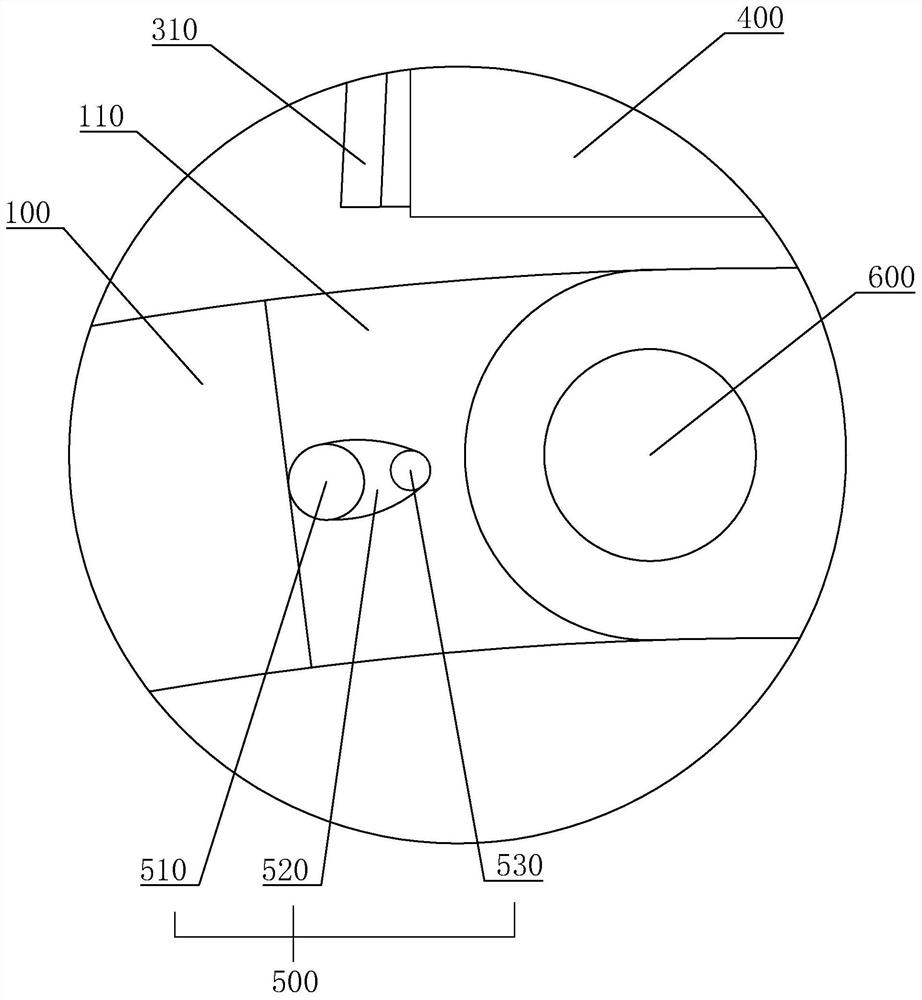

[0035] A pipeline non-destructive testing system that can adapt to different areas, refer to figure 1 , comprising a first arc-shaped rod 100 and a second arc-shaped rod 200 hinged at one end, the arcs of the first arc-shaped rod 100 and the second arc-shaped rod 200 are both greater than 90 degrees, and the first arc-shaped rod 100 and the second arc-shaped rod 100 The shaped rods 200 are concave or convex toward the same direction. An installation sleeve 300 is slidably connected at the connection between the first arc-shaped rod 100 and the second arc-shaped rod 200 , the probe 400 is installed in the installation sleeve 300 , and the first arc-shaped rod 100 and / or the second arc-shaped rod 100 is The rod 200 is provided with a locking mechanism 600 for locking the rotation angles of the first arc rod 100 and the second arc rod 200 . Rotate the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com