Drum-type workbench for translation, lifting and rotation of switch cabinet

A drum-type, workbench technology, applied to workbenches, manufacturing tools, etc., can solve problems such as high site requirements, low efficiency, and difficulty in switching and docking of switchgear, achieving efficient control and circulation, and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

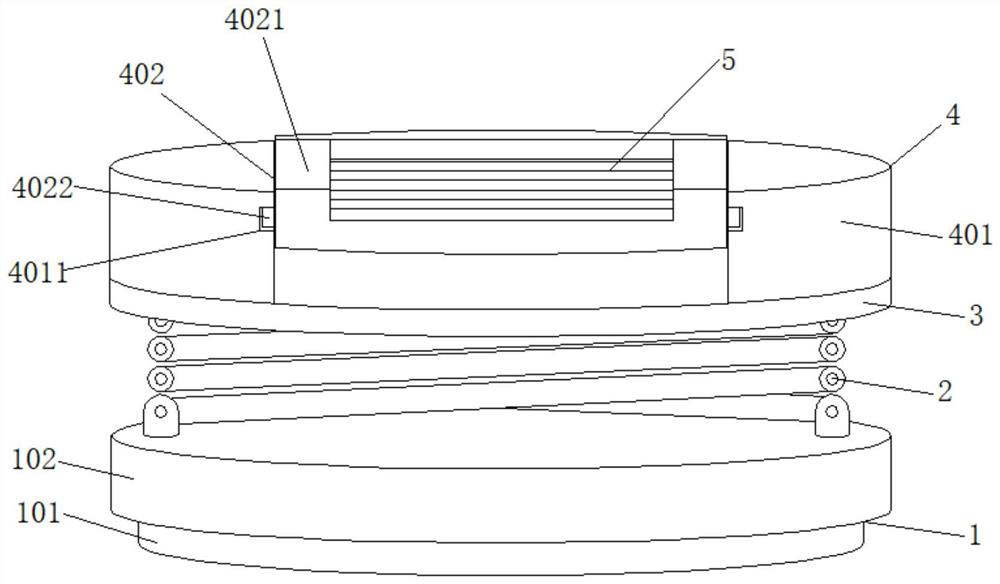

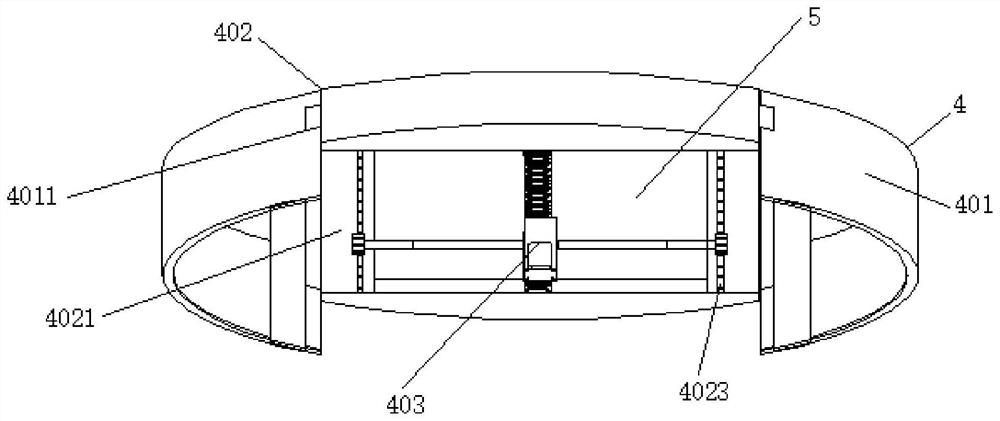

[0025] as Figure 1As shown, the present embodiment provides a roller table for translation, lifting and rotating of the switch cabinet; comprising a rotating mechanism 1, a lifting mechanism 2, a chassis 3, a translation mechanism 4 and a rolling conveyor mechanism 5, a rotating mechanism 1 comprising a fixed base 101 and a rotating platform 102, a rotating platform 102 is mounted on a fixed base 101, a lifting mechanism 2 is mounted on a rotating platform 102, the upper end of the lifting mechanism 2 is connected to the bottom of the chassis 3, and the upper part of the chassis 3 is installed with a translation mechanism 4, The translation mechanism 4 includes a translation table 402 in the middle of the fixed table 401 and the fixed station 401 on both sides, the translation table 402 is flanked by the beam 4021, the horizontal height of the beam 4021 is higher than that of the fixed table 401, the rolling conveyor mechanism 5 is installed in the middle of the two beams 4021. ...

Embodiment 2

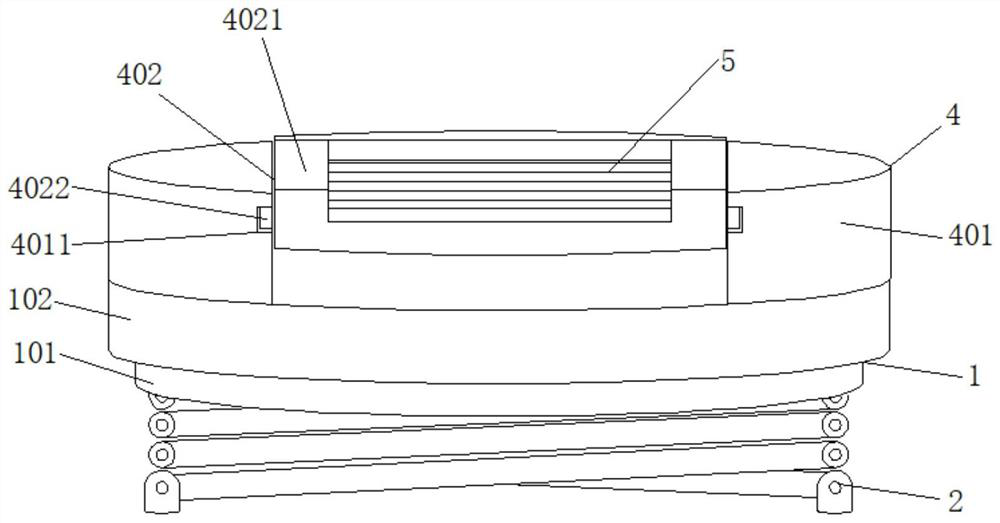

[0043] as Figure 3 As shown, the present embodiment provides a rotating structure above the lifting structure for translation, lifting and rotating of the roller table, comprising a lifting mechanism 2, a rotating mechanism 1, a translation mechanism 4 and a rolling conveyor mechanism 5, a rotating mechanism 1 comprising a fixed base 101 and a rotating platform 102, a rotating platform 102 is mounted on a fixed base 101, a fixed base 101 is installed at the upper end of the lifting mechanism 2, and a translation mechanism 4 is installed above the rotating platform 102, The translation mechanism 4 includes a translation table 402 in the middle of the fixed table 401 and the fixed station 401 on both sides, the translation table 402 is flanked by the beam 4021, the horizontal height of the beam 4021 is higher than that of the fixed table 401, the rolling conveyor mechanism 5 is installed in the middle of the two beams 4021.

[0044] Lifting mechanism 2 is scissor hydraulic lifting s...

Embodiment 3

[0056] as Figure 4 As shown, the present embodiment provides a switch cabinet flow system consisting of at least 2 sets of roller workbench for translation, lifting and rotating of the switch cabinet; comprising at least 2 sets of roller table, the drum table comprises a rotating mechanism 1, a lifting mechanism 2, a chassis 3, a translation mechanism 4 and a rolling conveyor mechanism 5, a rotating mechanism 1 comprising a fixed base 101 and a rotating platform 102, a rotating platform 102 mounted on a fixed base 101, a lifting mechanism 2 lower end mounted on a rotating platform 102, The upper end of the lifting mechanism 2 is connected to the bottom of the chassis 3, the upper part of the chassis 3 is installed with a translation mechanism 4, the translation mechanism 4 includes a translation table 402 in the middle of the two sides of the station 401 and a fixed station 401, the translation table 402 is flanked by the beam 4021, the horizontal height of the beam 4021 is higher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com