A 3D inspection machine for semiconductor components

A technology for components and semiconductors, applied in the field of 3D testing machines for semiconductor components, can solve the problems of inconvenient adjustment and inconvenient transportation of semiconductor components, and achieve the effects of improving detection accuracy, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

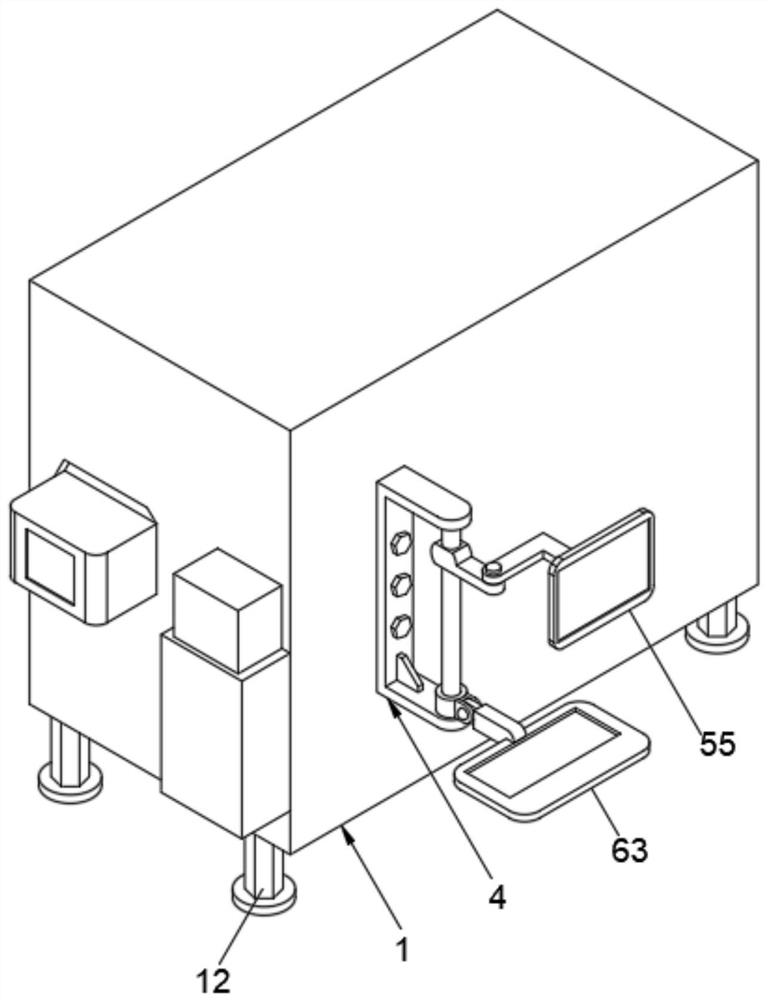

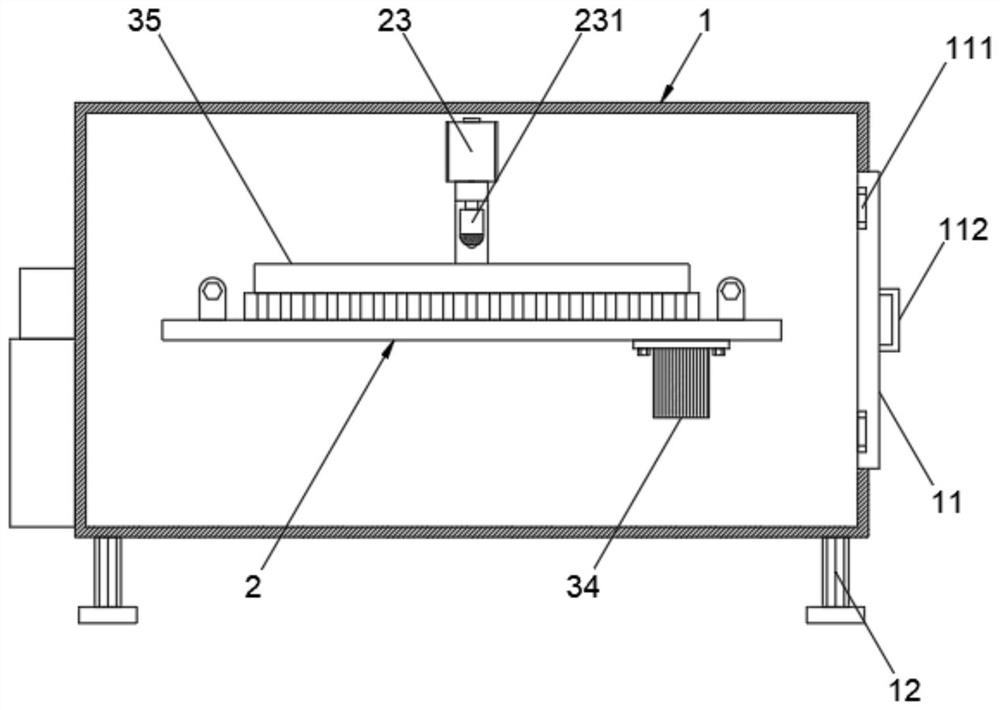

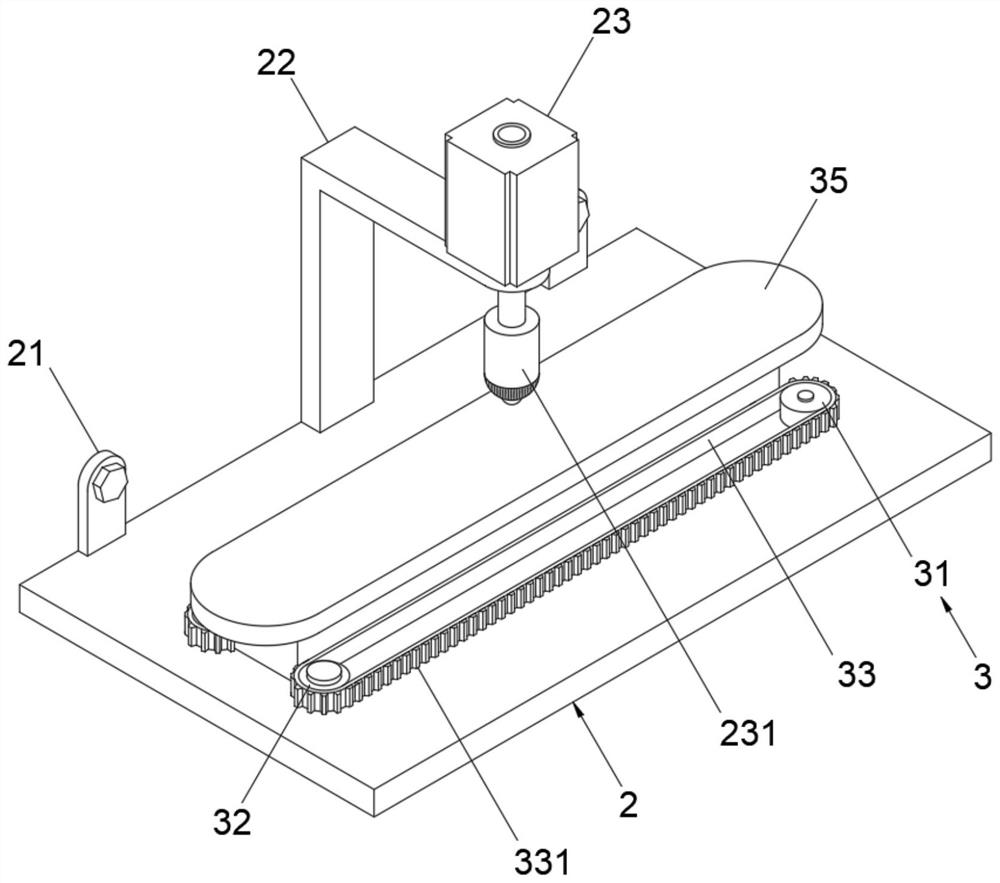

[0035] As a first embodiment of the present invention, a 3D inspection machine for semiconductor components, such as Figure 1-7Shown, comprise box body 1, the back surface of box body 1 is provided with box door 11, and box door 11 is provided with the joint of box body hinge 111, and box door 11 is hinged with box body 1 by hinge 111, and box body 1 There is a bottom plate 2 inside, and two fixing blocks 21 are tightly welded on one side of the bottom plate 2, and fixing bolts 211 are arranged on the fixing blocks 21, and the fixing blocks 21 are fixedly connected with the inner wall of the box body 1 through the fixing bolts 211, and the top of the bottom plate 2 The surface is provided with an L-shaped bracket 22, the vertical end of the L-shaped bracket 22 is tightly welded to the upper surface of the base plate 2, the horizontal end of the L-shaped bracket 22 is provided with a first through hole 221, and the L-shaped bracket 22 is equipped with a cylinder 23, A 3D camer...

Embodiment 2

[0042] As the second preferred embodiment of the present invention, the four corners of the lower surface of the box body 1 are provided with supporting feet 12, which is convenient to use the supporting feet 12 to support the box body 1, and prevent the bottom surface of the box body 1 from being damaged after being damp. corrosion.

Embodiment 3

[0044] As a third preferred embodiment of the present invention, a ring 341 is tightly welded on the motor 34, and first bolts 342 are arranged on both sides of the ring 341, and the ring 341 connects with the lower surface of the bottom plate 2 through the first bolt 342 For fixed connection, the lower surface of the bottom plate 2 is provided with a screw hole suitable for the first bolt 342 , so that the first bolt 342 is screwed into the screw hole, so as to facilitate fixing the motor 34 on the lower surface of the bottom plate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com