Integrated forming mold for main beam box body structure of unmanned aerial vehicle

A technology for forming molds and unmanned aerial vehicles, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of complex molding process and difficult integral molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the following briefly introduces the drawings that need to be used in the description of the embodiments or the prior art.

[0023] The box body structure of the main beam of the drone of the present invention is made of carbon fiber twill prepreg material, and is designed with a box body structure. in:

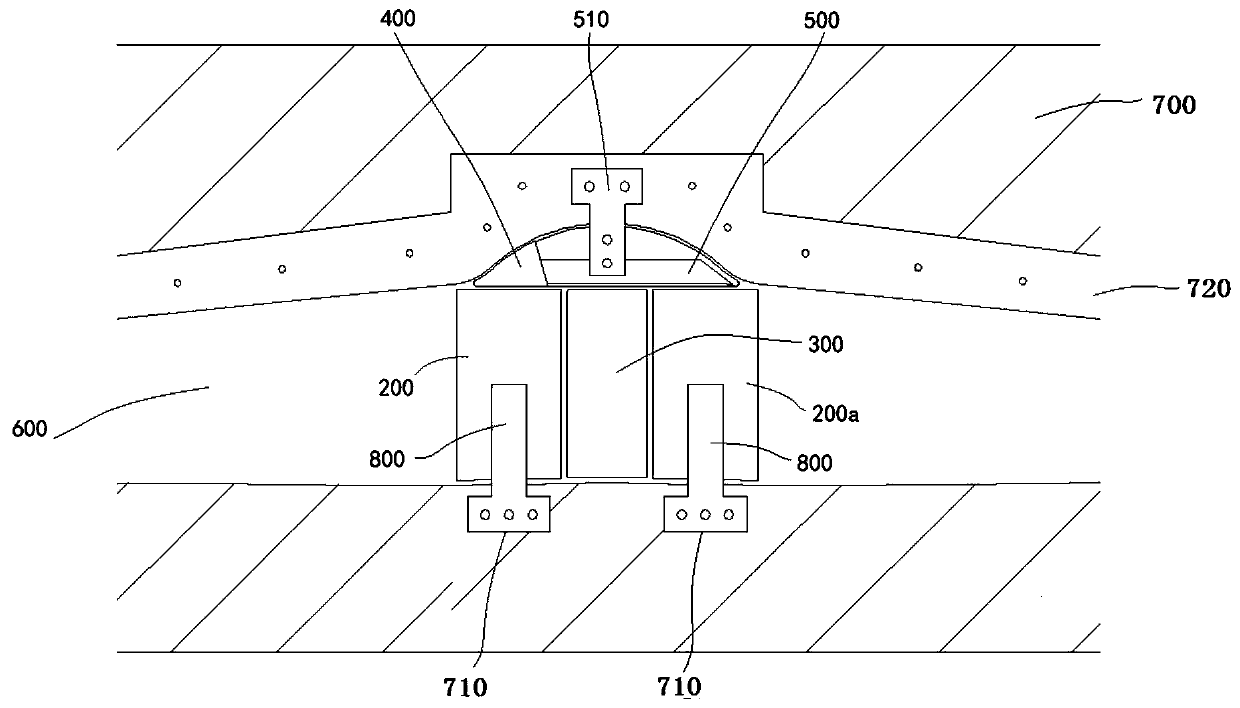

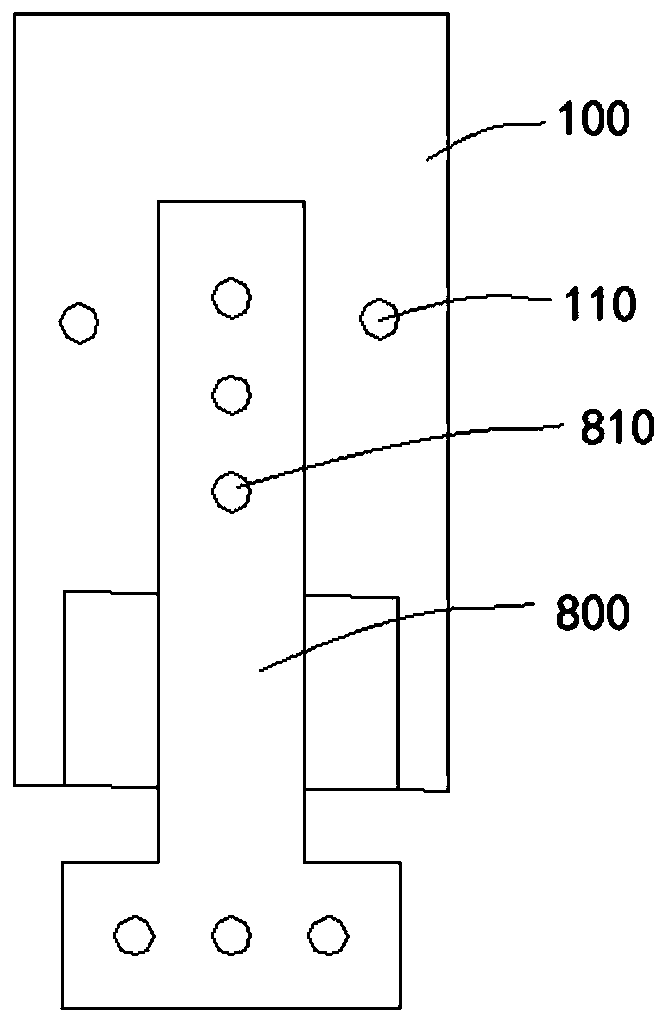

[0024] see figure 1 and figure 2 , the integrated molding mold for the main beam box structure of the UAV includes: main body forming tooling 700, 12 sets of positioning tooling 100 for laying, two sets of metal positioning tooling for curing 200, 200a, an expandable mandrel 300, conformal uniform The pressing plates 400, 500, 600 are integrally cured and molded by the autoclave process.

[0025] Three first positioning holes 710 are provided on the main body forming tool 700 .

[0026] During layup, each prepreg layup for positioning is positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com