Shearing part, transmission part, shearing assembly and door and window structure

A technology for transmission parts and doors and windows, applied in the field of doors and windows, can solve the problems affecting the installation efficiency of door and window installation parts, affecting the installation and adjustment efficiency of doors and windows, and falling out of door and window installation parts, so as to achieve convenient installation and adjustment, convenient installation and removal of installation parts, and simplified The effect of the installation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

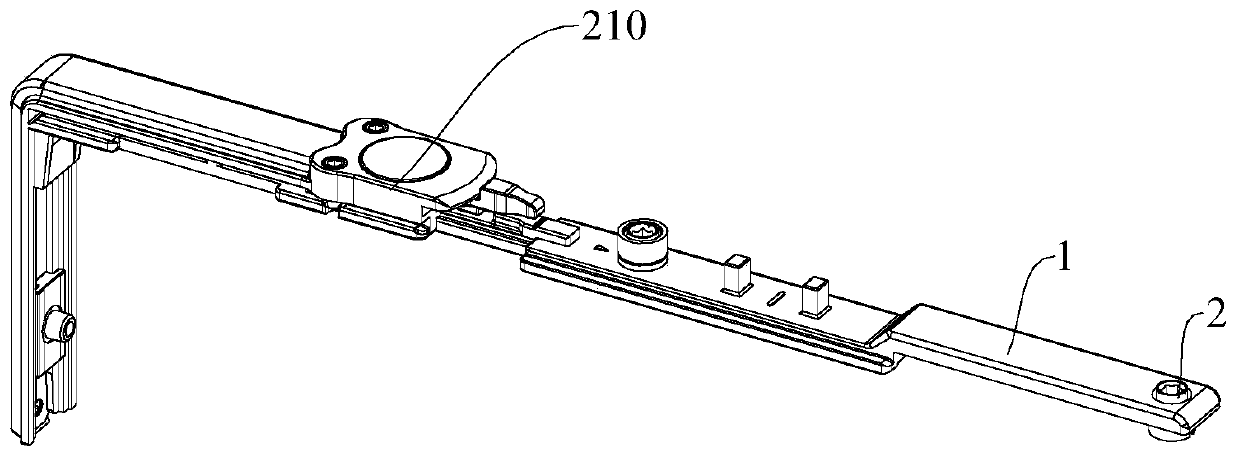

[0081] Refer below Figure 11-Figure 12 A shear assembly of a specific embodiment of the invention is described.

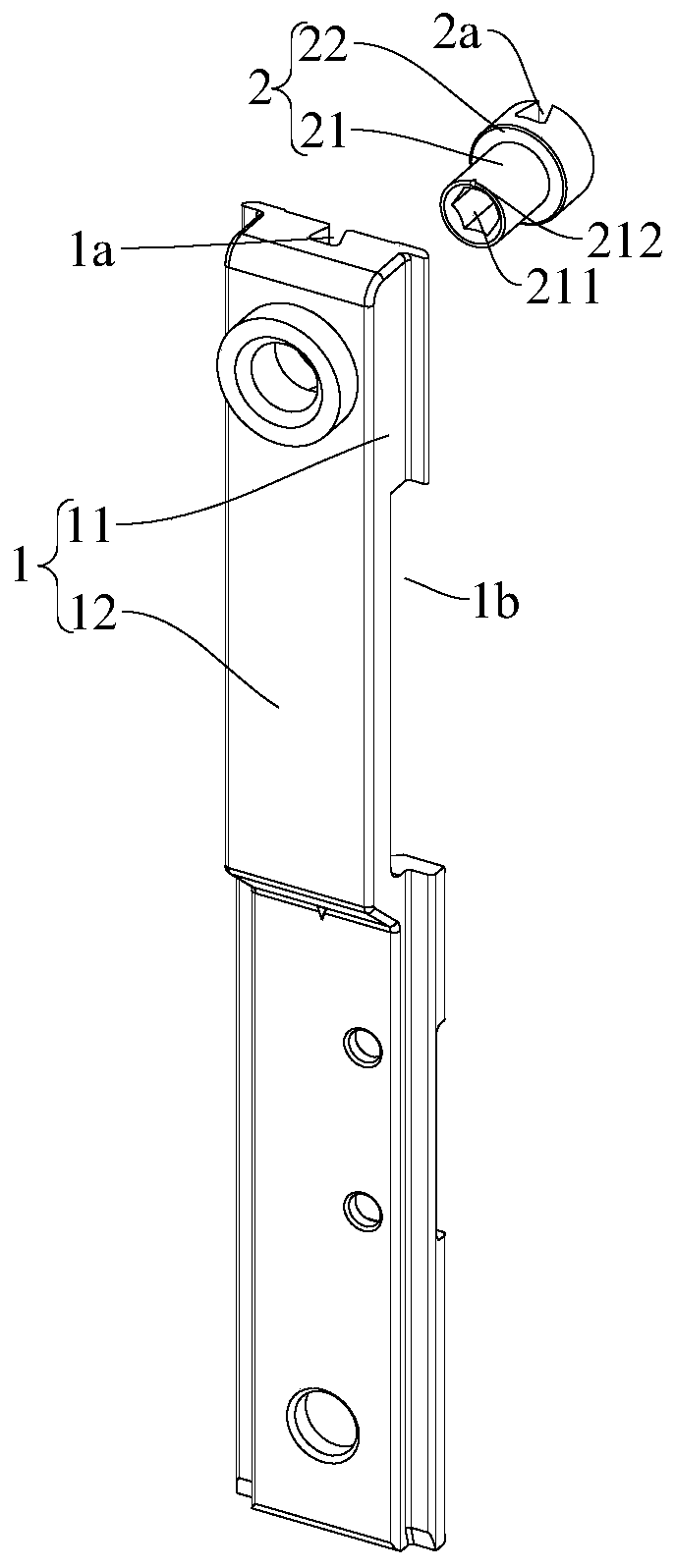

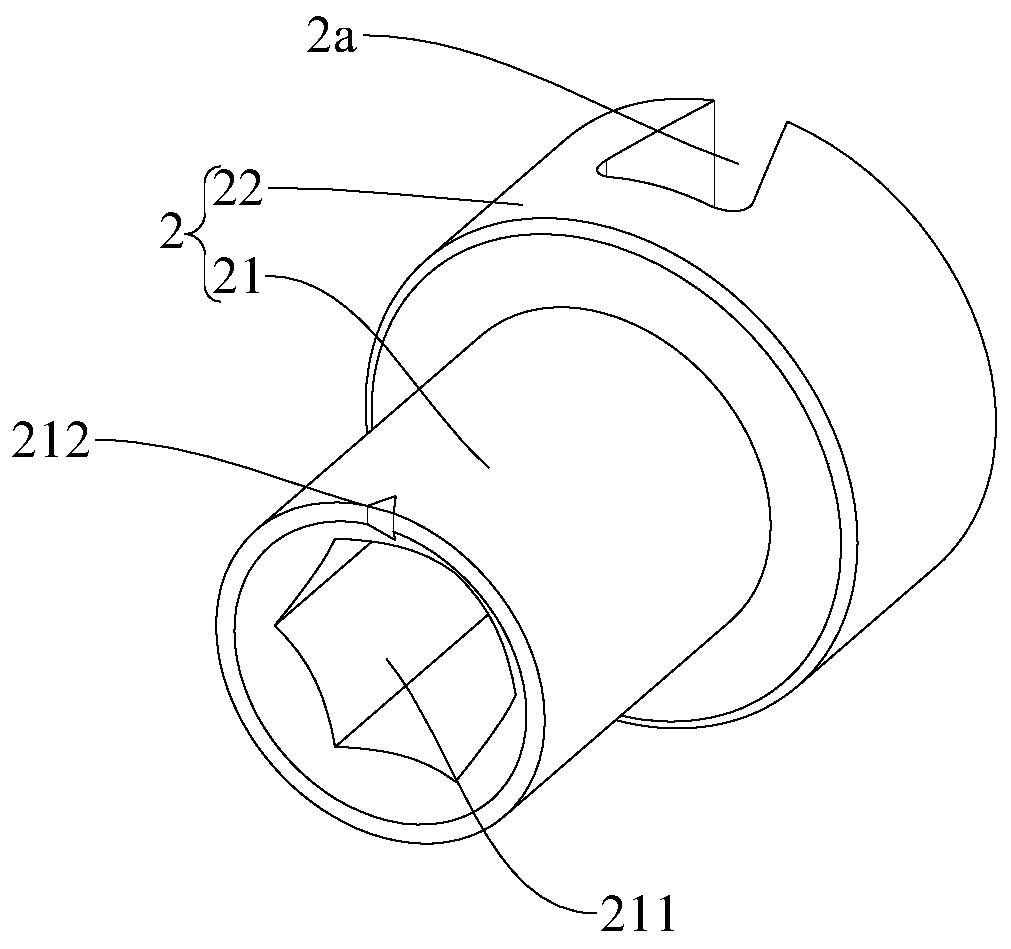

[0082] like Figure 11-Figure 12 As shown, the shearing assembly in this embodiment includes a shearing element and a transmission element 100 connected with the shearing element. The shearing piece includes a mounting piece 1 and a shearing piece 2. The mounting piece 1 is provided with a matching groove 1a and an adjusting groove 1b. The matching groove 1a is opened downwards, and the width of the matching groove 1a is in the upward direction. Gradually increasing, the matching groove 1a is suitable to be connected with the matching protrusion 100a on the transmission part 100, and one end of the transmission part 100 can extend into the adjustment groove 1b to adjust the relative position of the mounting part 1 and the transmission part 100, cut The block 2 is rotatably arranged on the mounting part 1. The shear block 2 is provided with a shear groove 2a conn...

Embodiment 2

[0084] like Figure 13-Figure 14 As shown, the structure of the shearing assembly in this embodiment is substantially the same as that of the shearing assembly in Embodiment 1. The difference is that the transmission member 100 is provided with limiting grooves on both sides of the mating protrusion 100a 100b, the mounting part 1 is provided with a limiting structure that cooperates with the limiting groove 100b. In this way, the phenomenon that the transmission part 100 is detached from the mounting part 1 can be better avoided.

Embodiment 3

[0086] like Figure 15 As shown, the structure of the cutout block 2 of this embodiment is the same as that of Embodiment 1. As shown in the figure, the mounting part 1 of this embodiment includes a sliding section, and the shearing block 2 is rotatably fitted on the sliding section. The transmission part 100 includes an adjustment section 110 and a connection section 120. The adjustment section 110 is provided with a matching protrusion 100a. The cross section of the cooperation protrusion 100a is a rectangle. The connection section 120 is connected to the end of the adjustment section 110 away from the mounting part 1. 120 is suitable for being connected with other hardware structures.

[0087] The door and window structure of the present invention includes a profile piece and the aforementioned shearing assembly, and the shearing assembly is installed on the profile piece. The door and window assembly of the present invention includes the above-mentioned shearing assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com