Glass plastic hybrid fixed-focus lens

A fixed-focus lens and lens technology, which is applied in the field of optical imaging, can solve the problems of few high-quality lenses with super large apertures, high cost, and low volume, so as to improve market competitiveness, reduce lens costs, and improve the quality of lenses. The effect of imaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

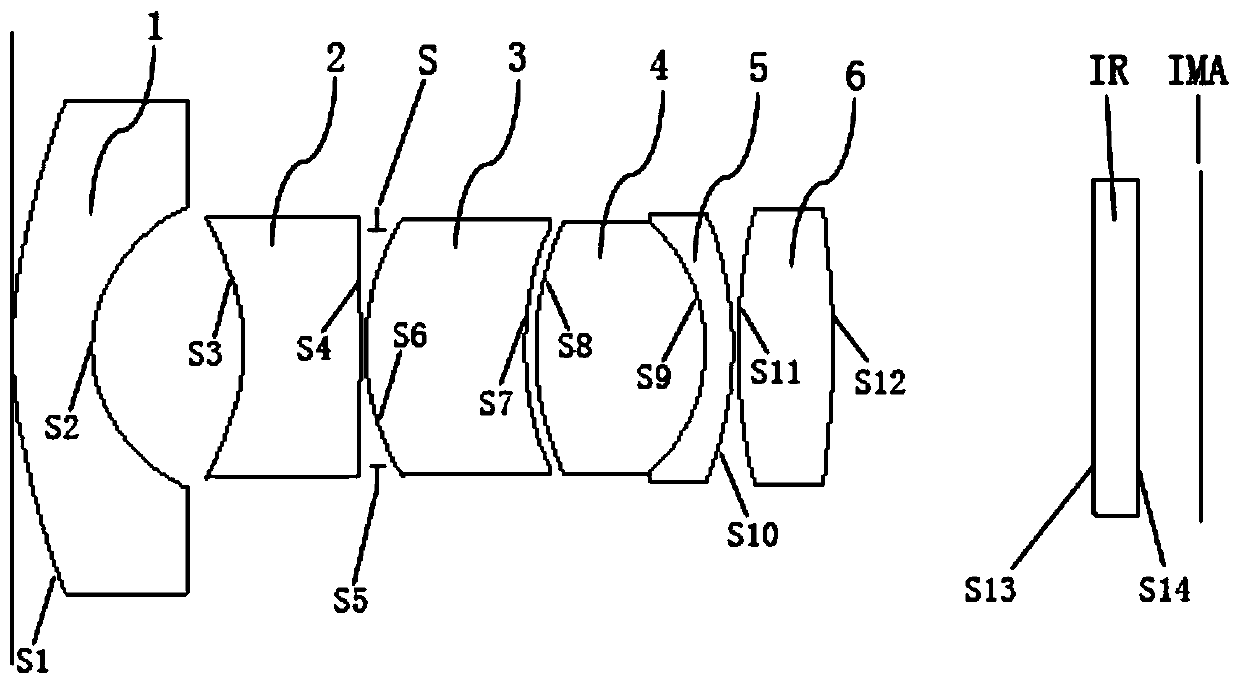

[0068] based on figure 1 The shown lens configuration is used to illustrate this embodiment.

[0069] The parameters of the camera lens in Embodiment 1 are as follows:

[0070] Effective focal length f=3.847mm, aperture FNO=1.954.

[0071] The following table 2 lists the focal length of each lens of the lens in this embodiment:

[0072] f1 f2 f3 f4 f5 f6 f1 / f f5 / f6 d / f -6.502 -8.964 16.727 11.708 -8.030 11.311 -2.241 -0.710 1.685

[0073] Table 2

[0074] Table 3 lists the relevant parameters of the lens lens of this embodiment, including surface type, radius of curvature, thickness, refractive index of material, and Abbe number:

[0075] Face number surface type R value thickness Refractive index Abbe number S1 Aspherical 5.206 1.505 1.5 56 S2 Aspherical 1.881 3.990 S3 Aspherical -3.395 2.208 1.5 56 S4 Aspherical -13.995 0.3 S5 STO Infinity -0.198 S6 Asph...

Embodiment approach 2

[0083] Image 6 It schematically shows the structural diagram of the glass-plastic hybrid fixed-focus lens according to the second embodiment of the present invention. The description according to this embodiment is as follows:

[0084] The parameters of the camera lens in the second embodiment are as follows:

[0085] Effective focal length f=3.847mm, aperture FNO=1.954.

[0086] The following table 5 lists the focal length of each lens of the lens in this embodiment:

[0087] f1 f2 f3 f4 f5 f6 f1 / f f5 / f6 d / f -7.606 -8.904 16.508 21.45 -7.393 11.489 -1.97 -0.643 1.801

[0088] table 5

[0089] Table 6 lists the relevant parameters of the lens lens of this embodiment, including surface type, radius of curvature, thickness, refractive index of material, and Abbe number:

[0090] Face number surface type R value thickness Refractive index Abbe number S1 Aspherical 7.844 1.5 1.5 56 S2 Aspherical 2.507 ...

Embodiment approach 3

[0098] Figure 11 It schematically shows the structural diagram of the glass-plastic hybrid fixed-focus lens according to the third embodiment of the present invention. The description according to this embodiment is as follows:

[0099] The parameters of the camera lens in the third embodiment are as follows:

[0100] Effective focal length f=2.998mm., aperture FNO=1.61.

[0101] What table 8 lists is the focal length of each lens of the present embodiment lens:

[0102] f1 f2 f3 f4 f5 f6 f1 / f f5 / f6 d / f -7.08 -8.758 18.661 11.523 -8.058 10.760 -2.362 -0.749 1.759

[0103] Table 8

[0104] The following table 9 lists the relevant parameters of the lens lens of this embodiment, including surface type, radius of curvature, thickness, refractive index of material, and Abbe number:

[0105] Face number surface type R value thickness Refractive index Abbe number S1 Aspherical 5.015 1.5 1.5 56 S2 Aspherical...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap