High-temperature fretting fatigue life prediction model based on continuous medium damage mechanics and method thereof

A life prediction model and fretting fatigue technology, applied in the fields of instrumentation, calculation, electrical and digital data processing, etc., can solve the problems of poor fretting fatigue life prediction effect and complex temperature effects of fretting fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below through specific embodiments.

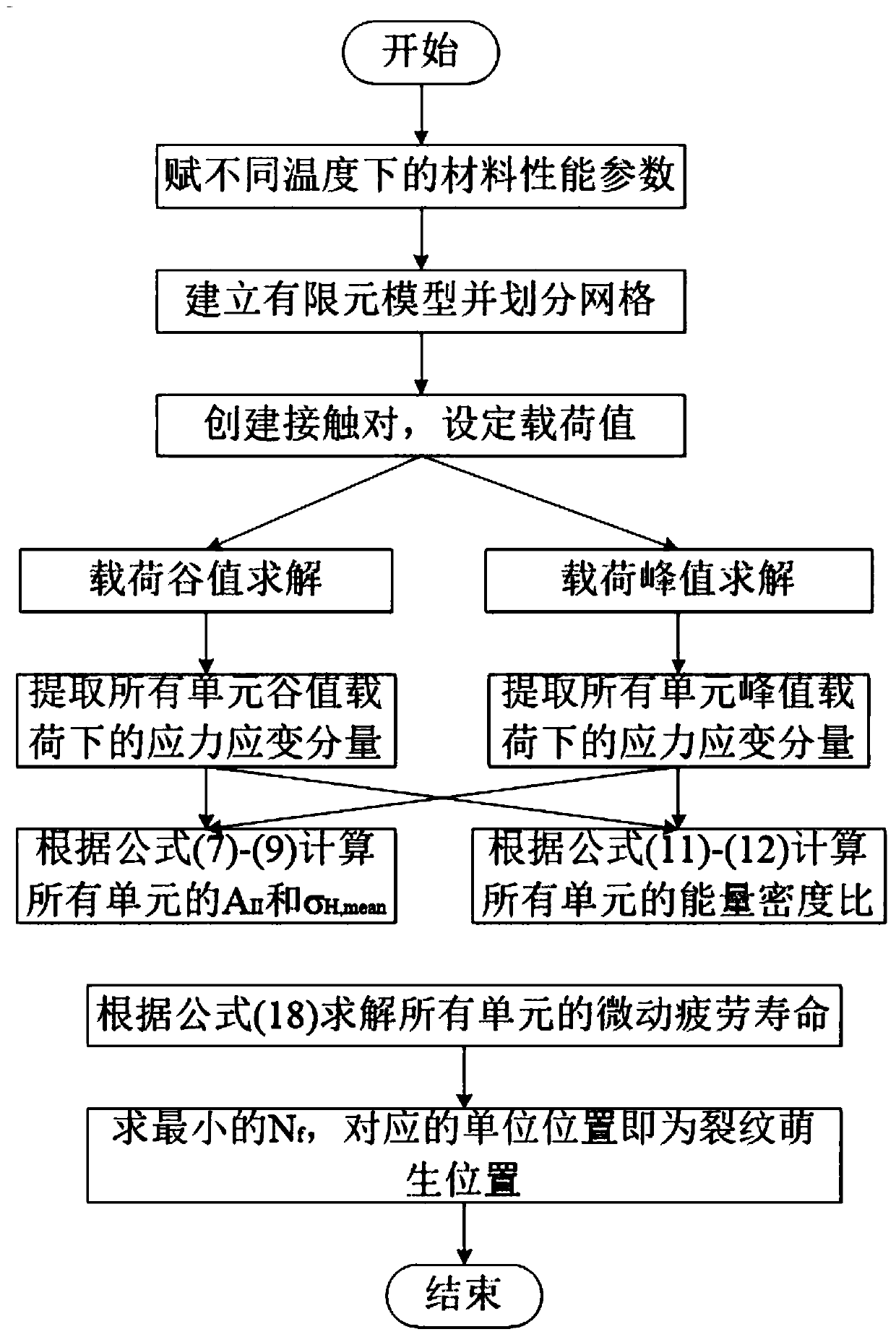

[0068] A method for constructing a high-temperature fretting fatigue life prediction model based on continuum damage mechanics, comprising the following steps:

[0069] Step 1. According to the nonlinear damage accumulation model (NLCD model) based on continuum damage mechanics, the damage parameter D is defined. The damage parameter D is 0, which means the initial undamaged state; the damage parameter D is 1, and fatigue damage is considered to occur; The loading stress of the nonlinear damage accumulation model takes into account the maximum stress and the average stress, and its functional relationship is:

[0070] dD=f(σ max ,σ m ,D)dN (1)

[0071] In the formula, D is the damage parameter, σ max is the maximum stress, σ m is the average stress, N is the fatigue life;

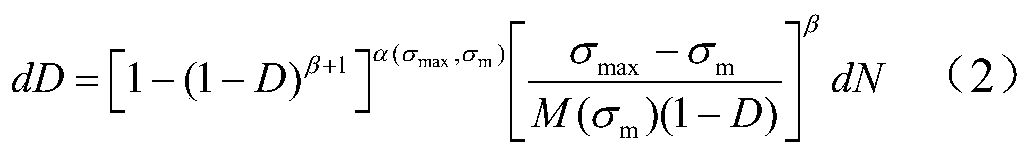

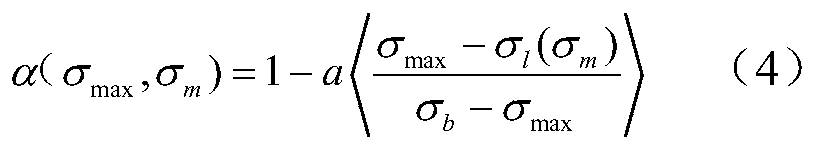

[0072] Step 2, the nonlinear fatigue damage evolution expression of the nonlinear damage ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com