Wind source type multi-bin automatic food material feeding electric rice cooker

A technology for automatic warehouse and ingredients, which is applied to the structure of cooking utensils, cooking utensils, household utensils, etc., can solve the problem that different ingredients cannot be automatically added in batches, the soaking time affects the quality and taste, and the variety of ingredients cooked in an electric cooker is limited. and functional issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

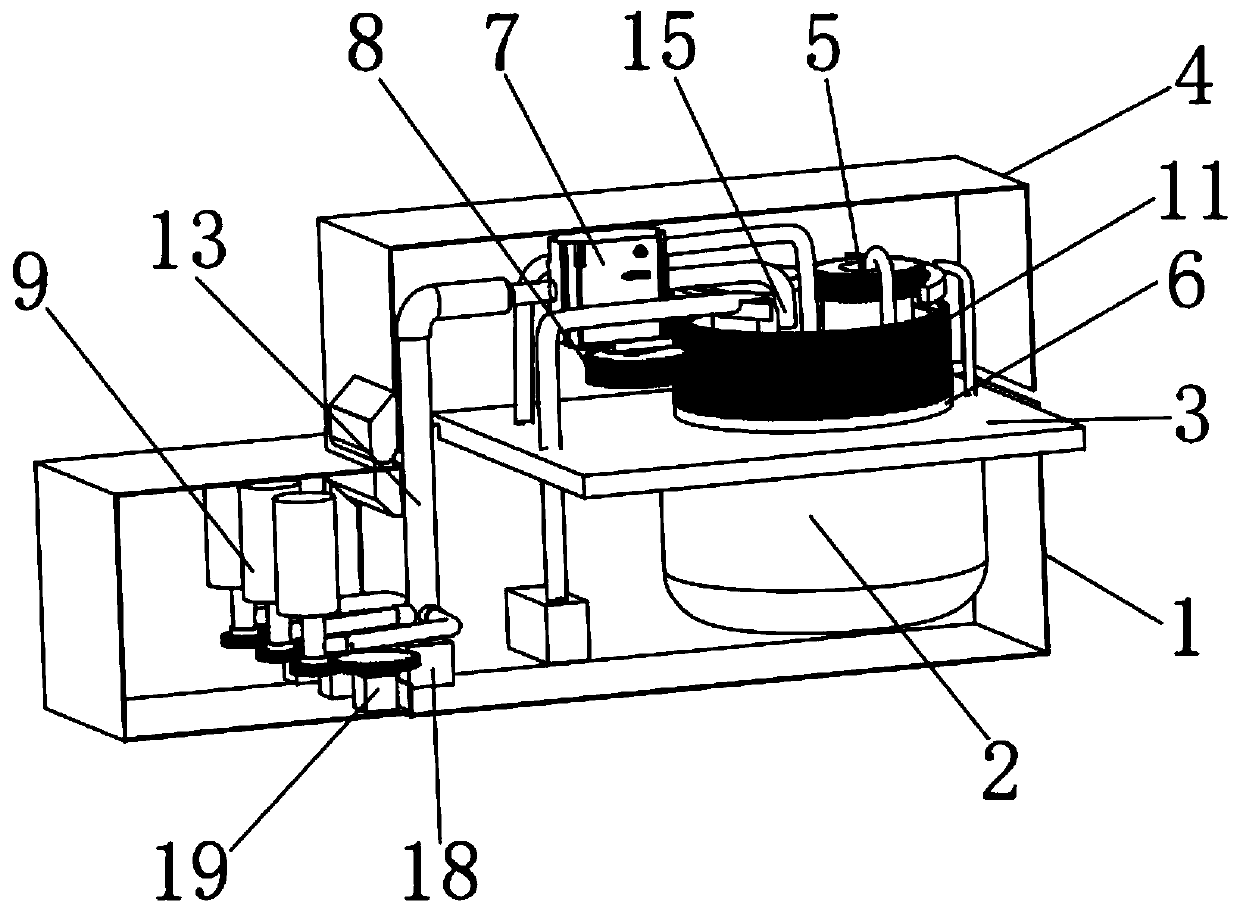

[0044] Such as figure 1As shown, the rice adding mechanism includes a multi-cage type rice bin 9, a rice bin output device, an air source type food material delivery mechanism, and a food material delivery mechanism, wherein the multi-bin type rice bin 9 has three small bins, and the rice bin type rice output device is Three, the rice output devices of the three rice bins are all screw-type rice valves, and each small bin is matched with a screw-type rice valve; the air source type material conveying mechanism has an air source device and a material conveying pipe. The lower end of the material conveying pipe is provided with three conveying pipe material inlets, and the outer sides of the three conveying pipe material inlets are all provided with windshield devices; the respective small warehouse food outlets 17 of the three small warehouses are respectively connected to the windshield through screw-type rice valves. The wind-shielding body of the device enters the rice inlet...

Embodiment 2

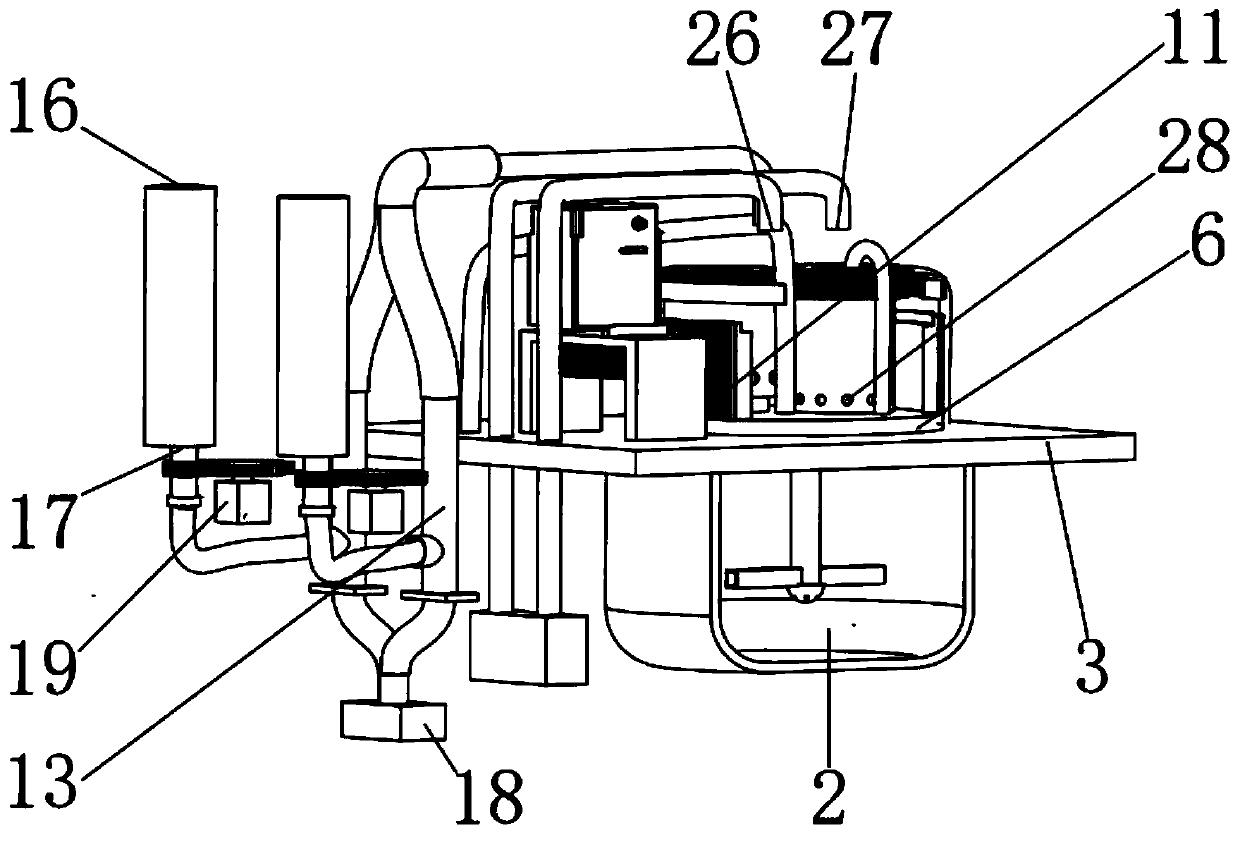

[0048] Such as figure 2 As shown, the rice adding mechanism includes a multi-storey rice storehouse 9, a rice storehouse rice output device, an air source type food material conveying mechanism, and a food material delivery mechanism, wherein the multi-storey type rice storehouse 9 has two small warehouses, and the two small warehouses are two. The bins are placed side by side; there are two rice outlet devices, both of which are screw-type rice valves, and each small bin is matched with a screw-type rice valve, which is used for Carry out metering of added rice; the air source food delivery mechanism has an air source device and two food delivery pipes, and the two food delivery pipes are set in one-to-one correspondence with the two small warehouses; the two small warehouses share the food delivery mechanism for food delivery After the food materials in the two small warehouses flow out from the respective small warehouse food material outlets 17, they all flow into the del...

Embodiment 3

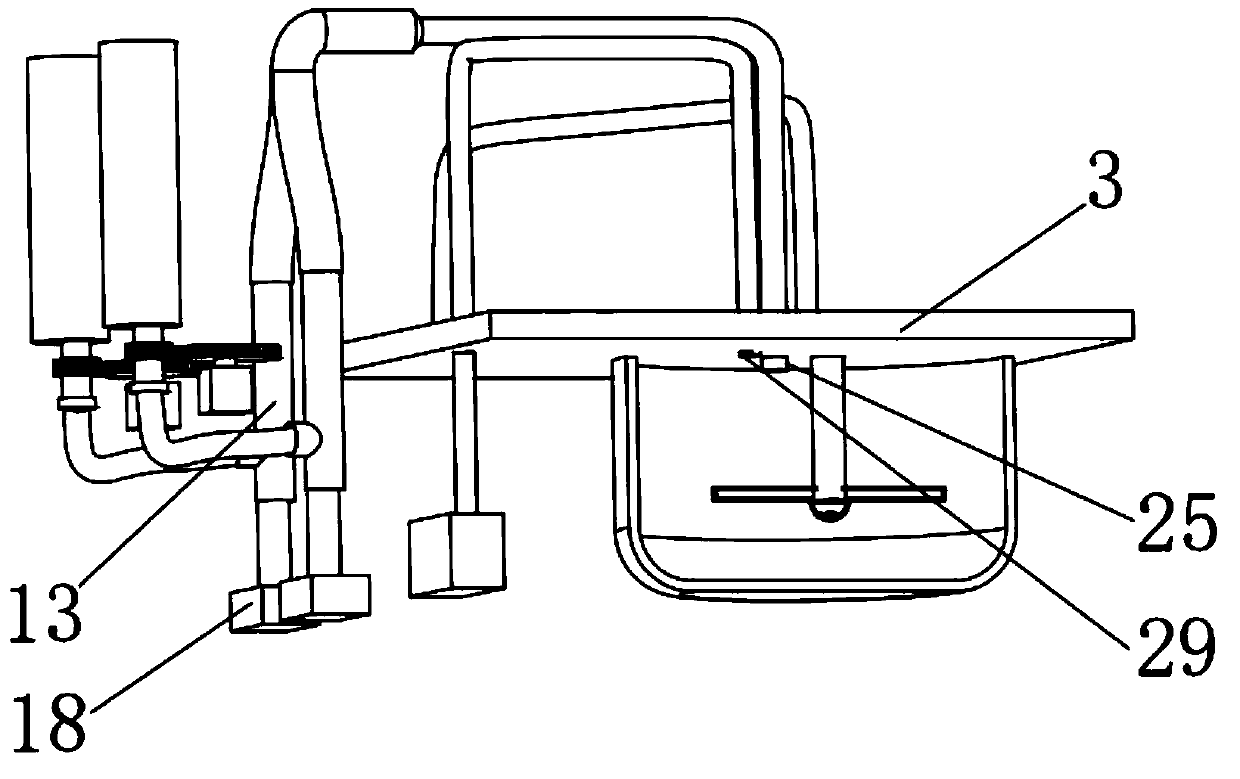

[0052] Such as image 3As shown, the rice adding mechanism includes a multi-compartment rice bin 9, a rice bin rice output device, and an air source type material conveying mechanism, wherein the multi-compartment rice bin 9 has two small bins, and the two small bins are placed side by side. ; There are two rice outlet devices in the rice bin, and the two rice bin rice outlet devices are screw-type rice valves. Each small bin is matched with a screw-type rice valve, and the screw-type rice valve is used for adding rice. The air source type food material conveying mechanism has two air source devices and two food material delivery pipes, and the two air source devices and the two food material delivery pipes are respectively set in one-to-one correspondence with the two small warehouses; the food materials in the two small warehouses After flowing out from the respective small warehouse food outlets 17, they all flow into the delivery pipe food inlets 14 of the respective food ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com