A kind of production method and production equipment of lithium-ion battery organic electrolyte

An organic electrolyte and lithium-ion battery technology, which is applied in the manufacture of secondary batteries, electrochemical generators, electrolyte batteries, etc., can solve the problems of high cost and inefficient production methods, reduce the cost of production equipment and improve production efficiency , Improve the effect of joining speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

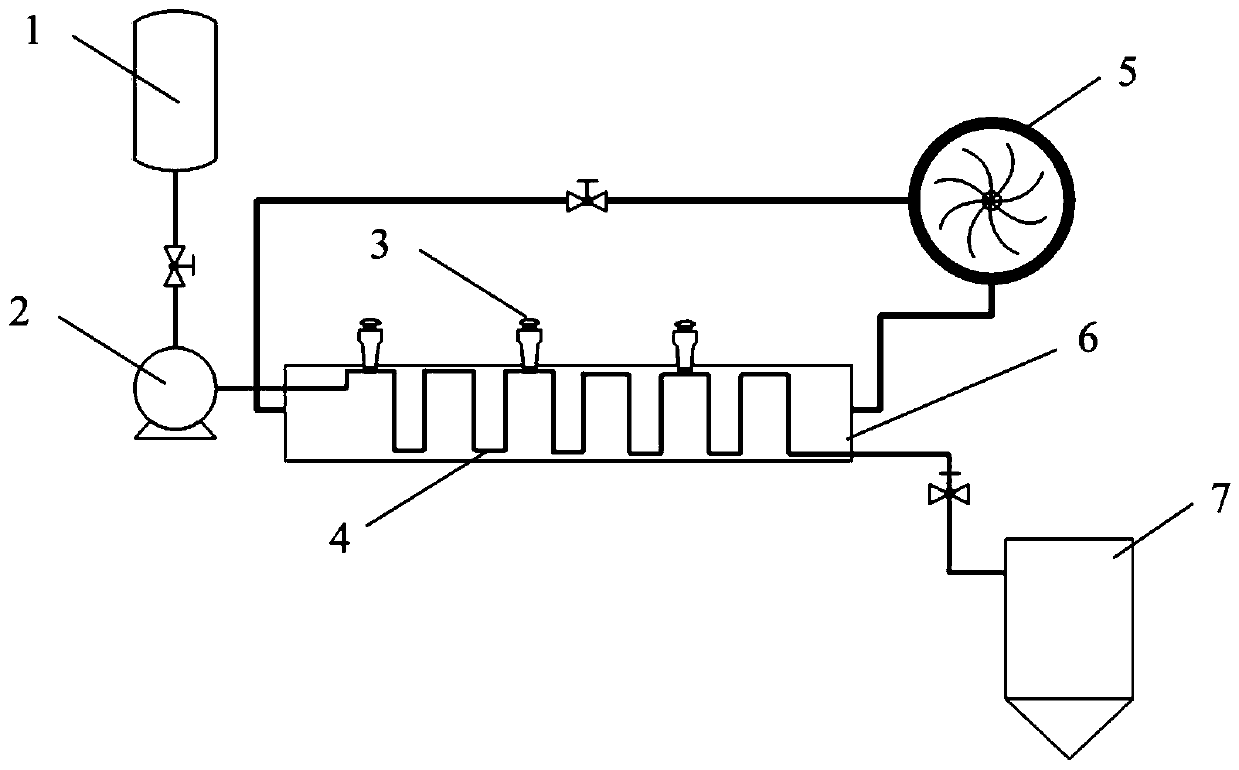

[0054] like figure 1 As shown, the first embodiment provides a production equipment for an organic electrolyte of a lithium ion battery, including a solvent mixing tank 1 , a pump 2 , a pipelined dissolving system, a cooling system and a finished product tank 7 . Among them, the pipelined dissolving system consists of pipelines 4 , and the cooling system includes a cooling device 5 and a freezing liquid tank 6 .

[0055] The solvent mixing tank 1 communicates with the front end of the pipeline 4 through the pump 2 , and the end of the pipeline 4 communicates with the finished product tank 7 . The frozen liquid tank 6 is loaded with the frozen liquid, the pipeline 4 is completely immersed in the frozen liquid of the frozen liquid tank 6, and the cooling device 5 is used for cooling the frozen liquid in the cooling tank. In the present embodiment, ethylene glycol is selected as the freezing liquid, the material of the pipeline 4 is selected as stainless steel which has undergon...

example 2

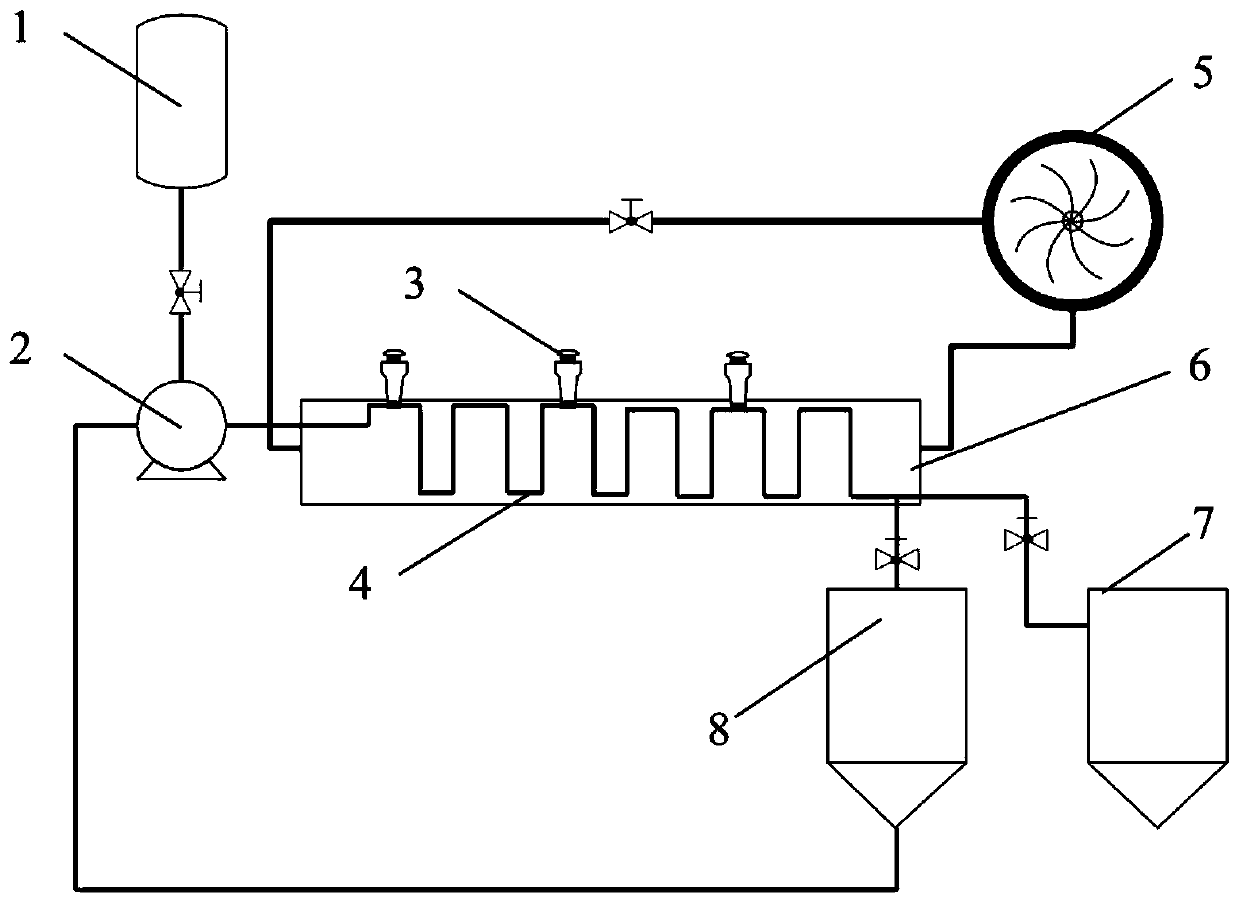

[0067] like figure 2 As shown, the second embodiment provides a production equipment for an organic electrolyte of a lithium ion battery, including a solvent mixing tank 1 , a pump 2 , a pipelined dissolving system, a cooling system, a buffer tank 8 and a finished product tank 7 . Among them, the pipelined dissolving system consists of pipelines 4 , and the cooling system includes a cooling device 5 and a freezing liquid tank 6 .

[0068] The solvent mixing tank 1 communicates with the front end of the pipeline 4 through the pump 2 , and the end of the pipeline 4 communicates with the finished product tank 7 . One end of the buffer tank 8 is communicated with the end of the pipeline 4, and the other end of the buffer tank 8 is communicated with the front end of the pipeline 4 through the pump 2. The buffer tank 8, the pump 2 and the pipeline 4 form a closed circuit. The freezing liquid tank is loaded with the freezing liquid, the pipeline 4 is completely immersed in the free...

example 3

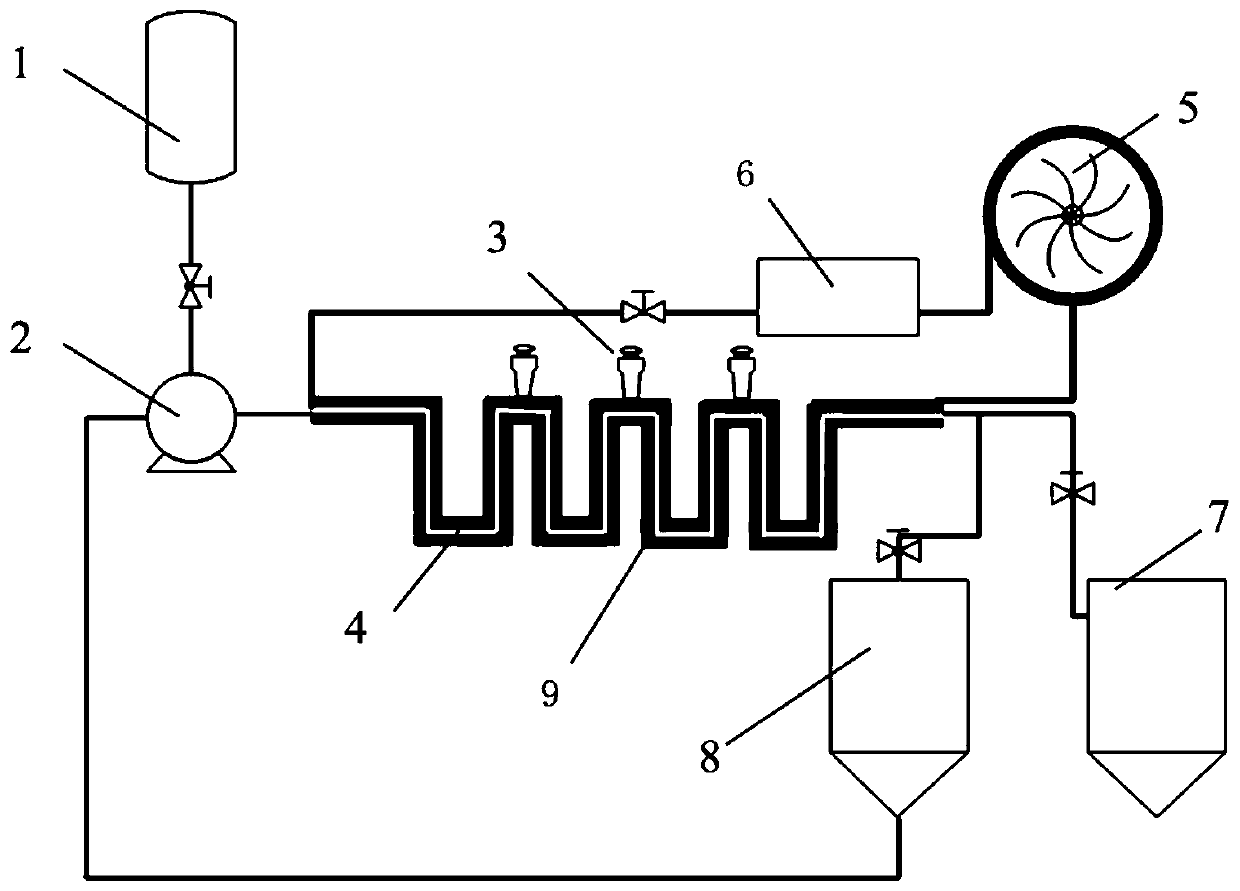

[0082] like image 3 As shown, the third embodiment provides a production equipment for an organic electrolyte of a lithium ion battery, including a solvent mixing tank 1 , a pump 2 , a pipelined dissolving system, a cooling system, a buffer tank 8 and a finished product tank 7 . The pipelined dissolving system consists of pipelines 4 , and the cooling system includes a cooling device 5 , a freezing liquid tank 6 and a freezing jacket 9 .

[0083] The solvent mixing tank 1 is further communicated with the front end of the pipeline 4 through the pump 2 , and the end of the pipeline 4 is communicated with the finished product tank 7 . One end of the buffer tank 8 is communicated with the end of the pipeline 4, and the other end of the buffer tank 8 is communicated with the front end of the pipeline 4 through the pump 2. The buffer tank 8, the pump 2 and the pipeline 4 form a closed circuit. The refrigerating liquid tank 6 and the refrigerating sleeve 9 are loaded with refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com