A fast unloading device with adjustable weight

A weight and fast technology, applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of tedious and time-consuming weight adjustment, low filling efficiency, etc., and achieve the effect of saving manpower, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

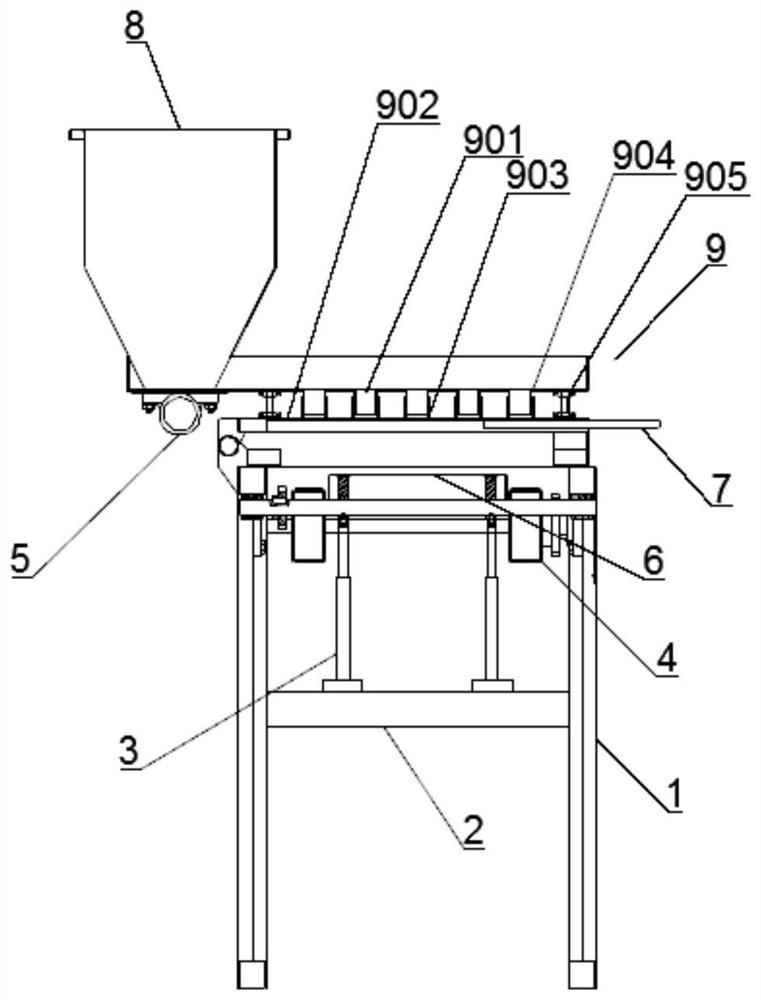

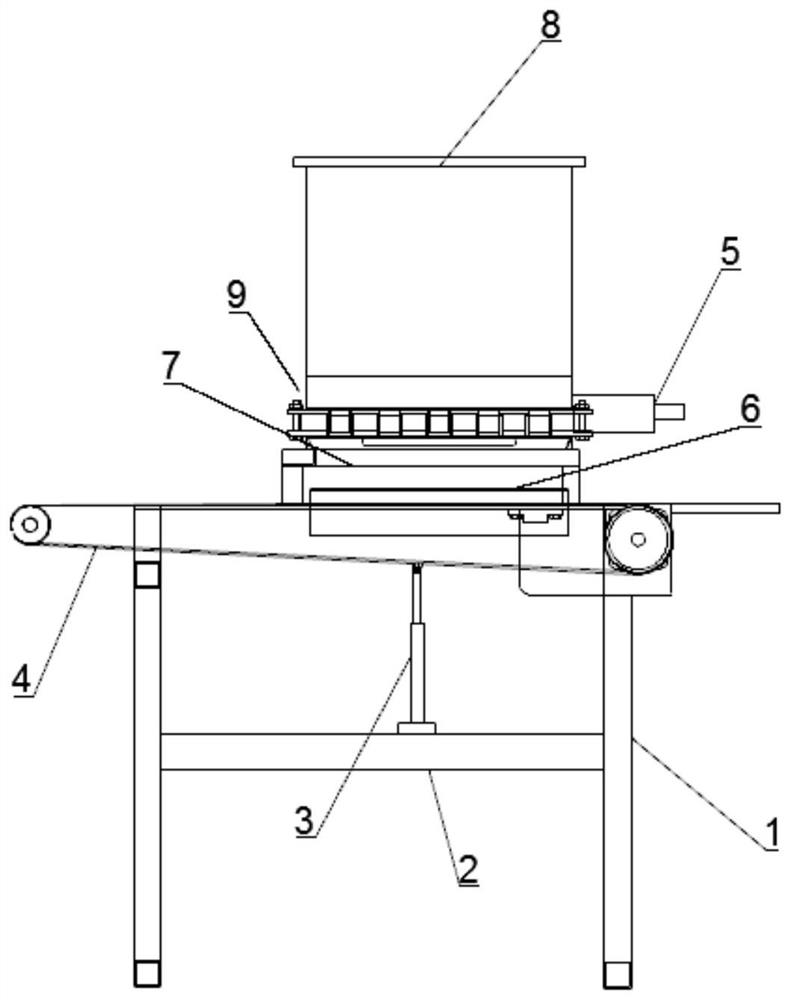

[0023] Such as figure 1 and 2 As shown, a fast unloading device with adjustable components includes a vibrator 5, a feed hopper 8, a material distribution mechanism 9, a discharge gate 7, a base 6, and a jacking mechanism. The feed hopper 8 is an upper and lower opening, In a bucket shape that gradually becomes smaller downwards, the feeding hopper 8 is fixedly combined with the distributing mechanism 9,

[0024] Raw materials are scattered from the feeding hopper 8 into the material distribution mechanism 9, and the material distribution mechanism 9 adjusts the weight of a single raw material through a plurality of sleeved double pipes. Described vibrator 5, described vibrator 5 can accelerate blanking, evenly distribute and dense raw material,

[0025] The discharge gate 7 is installed below the distribution mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com