Dispensing device for instrument

A technology of dispensing device and instrument, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of low efficiency, different instrument sizes, and small application range, and achieve fast dispensing, convenient adjustment, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

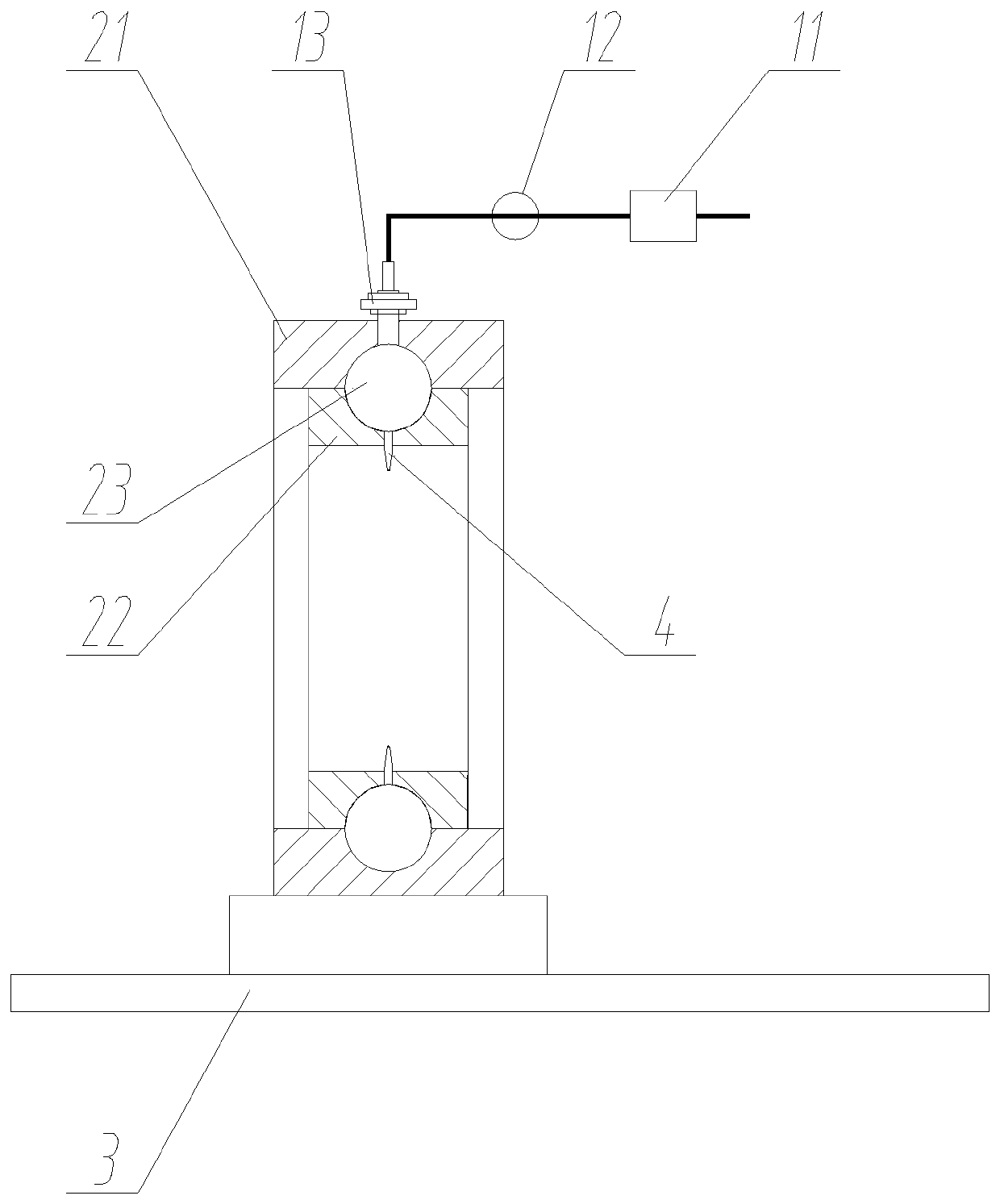

[0018] Such as figure 1 , figure 2 As shown, the dispensing device for an instrument includes a sleeve assembly and a colloid assembly 4;

[0019] The sleeve assembly includes an outer sleeve 21 and an inner sleeve 22, the outer sleeve 21 is hermetically fitted outside the inner sleeve 22, and an annular cavity 23 is provided between the inner sleeve 22;

[0020] The outside of the outer sleeve 21 is provided with a through hole 45 connected to the annular cavity 23, the through hole 45 is connected to the storage tank through the connecting pipe 13, and the connecting pipe 13 is provided with a pump 11; the inner sleeve 22 is provided with a colloid assembly 4 facing inward. ;

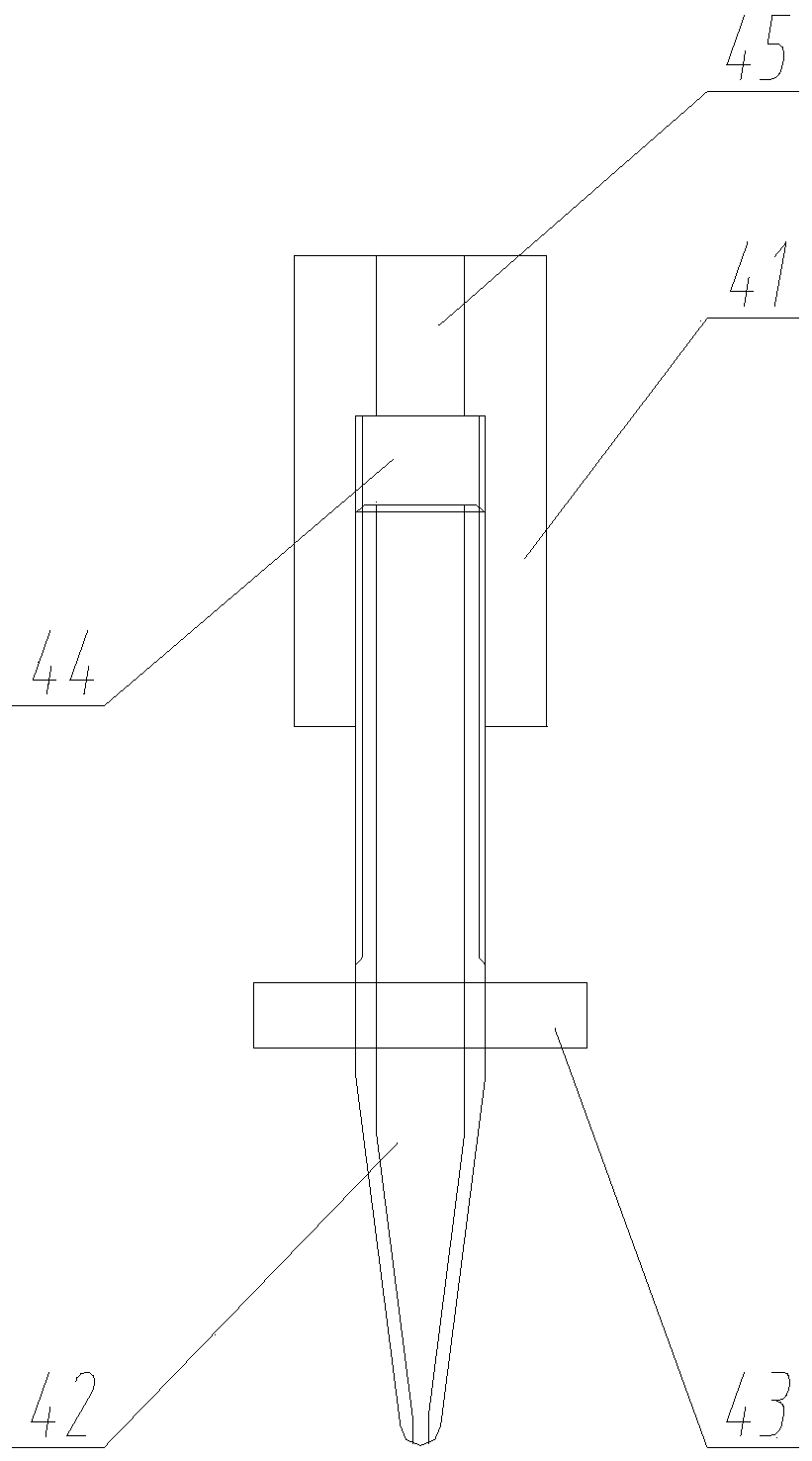

[0021] The glue assembly 4 includes a glue head 41 and a glue hose 42;

[0022] The lower end of the rubber head 41 is provided with a blind cavity 44, the upper end of the blind cavity 44 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com