Rheological property testing method for semi-solid material with flat/decorative surface

A technology for rheological properties and decorative surfaces, applied in the directions of flow properties, analytical materials, measuring devices, etc., which can solve the problems of different rheological properties and low data repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

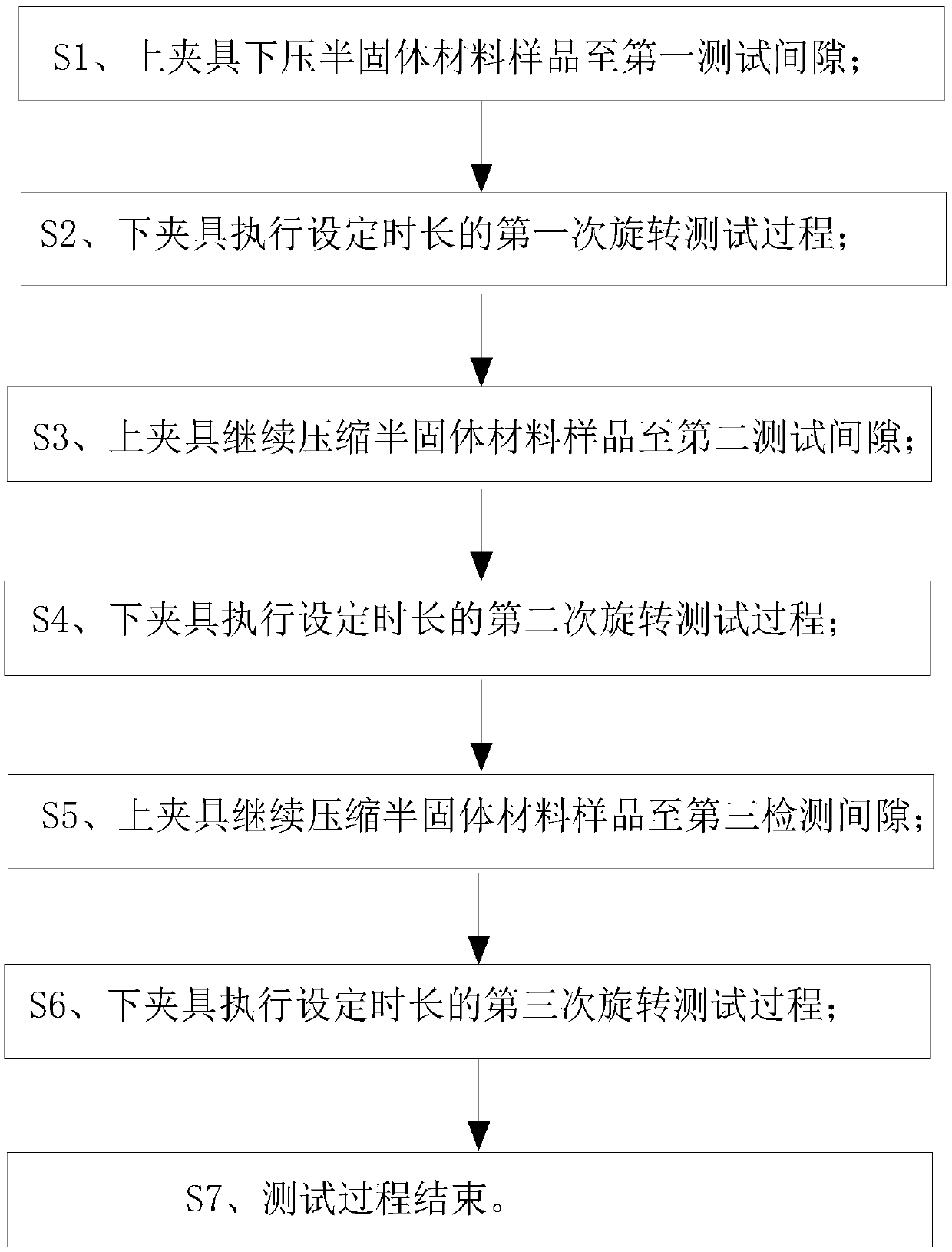

[0048] This embodiment provides a method for testing the rheological properties of a semi-solid material with a flat / decorative surface, using a rotational rheometer to test, including:

[0049] The gap between the upper clamp and the lower clamp of the rotational rheometer is gradually reduced to compress the semi-solid material sample loaded on the lower clamp;

[0050] In the process of gradually compressing the semi-solid material sample, the rheological properties of the semi-solid material sample are tested continuously or at intervals.

[0051] In the present invention, the construction process of workers / machines is simulated, and in the process of gradually compressing the semi-solid material sample, the rheological properties of the semi-solid material are tested to obtain rheological parameters with higher reference value. The present invention aims at semi-solid The actual use of materials In the process of compressing semi-solid materials, test their rheological p...

Embodiment 2

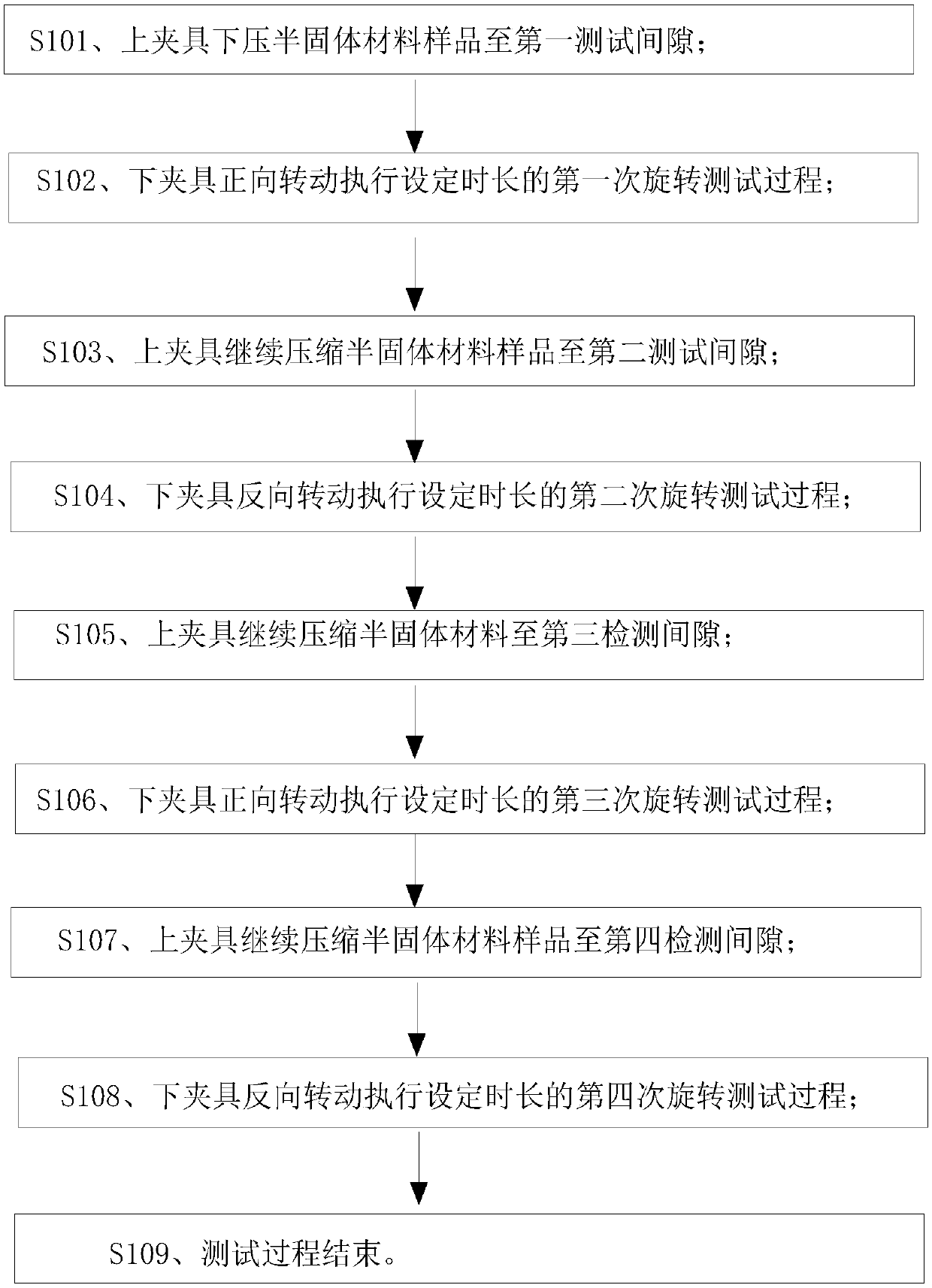

[0079] On the basis of the first embodiment, the second embodiment further takes into account the reciprocating scraping of the semi-solid material by construction personnel during the construction process, and provides a rheological property test method of the semi-solid material.

[0080] The rotational rheometer test is used, including: the lower fixture of the rotational rheometer performs a positive rotation relative to the upper fixture to forwardly shear the semi-solid material sample, and reverse rotation to reversely shear the semi-solid material sample In the test process of the semi-solid material sample, test data are obtained during the test process of forward and reverse shearing of the semi-solid material sample, so as to comprehensively calculate the rheological parameters of the semi-solid material sample.

[0081] In the above scheme, the rheological properties of forward-shear semi-solid material samples and reverse-shear semi-solid material samples are teste...

Embodiment 3

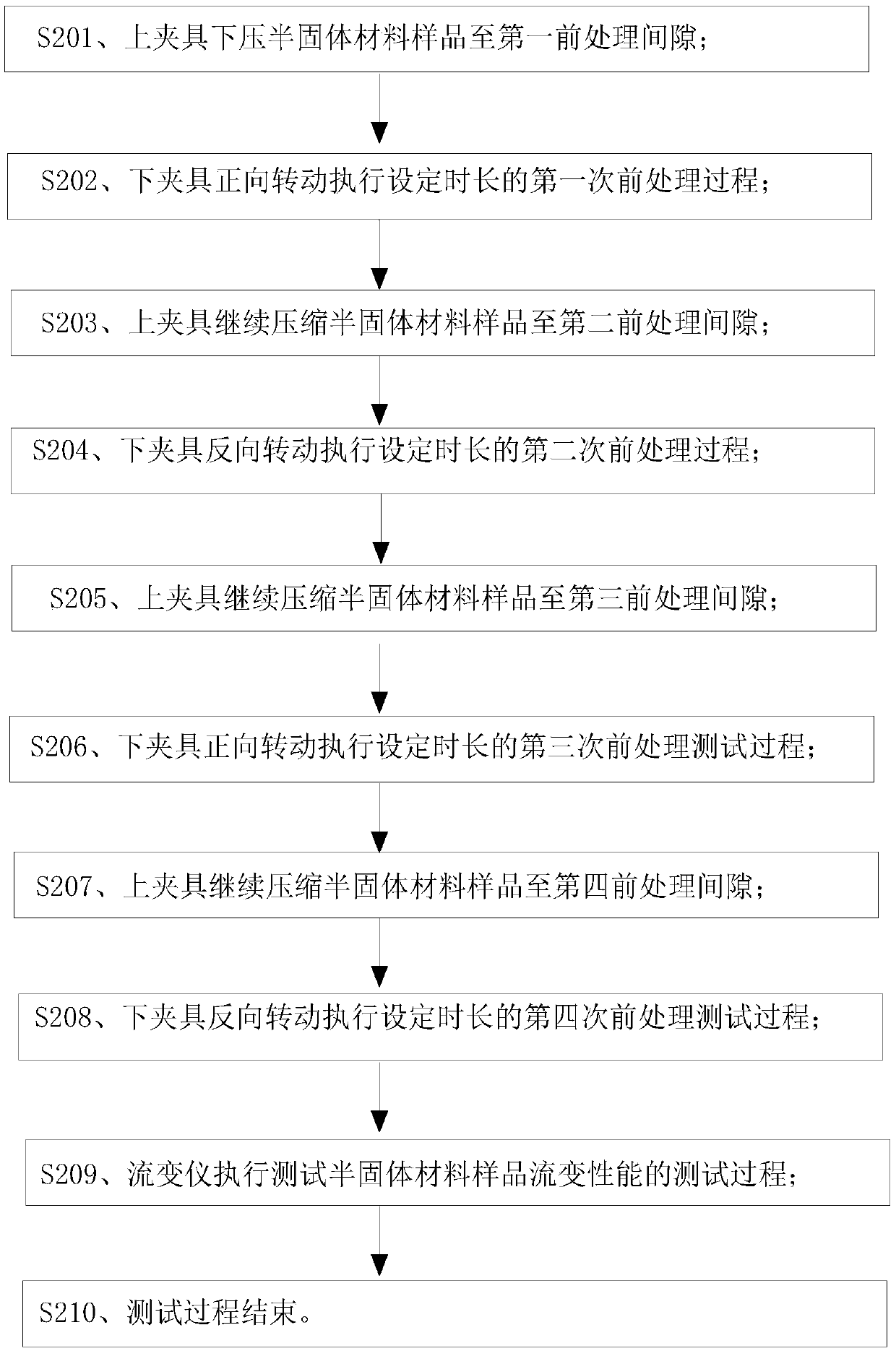

[0113] Before scraping the semi-solid material, the worker will also adjust the state of the semi-solid material, such as using a batch knife to mix the semi-solid material evenly, and then scrape it on the wall, so this process takes into account the actual During the test, more test results with reference value will be obtained.

[0114] On the basis of Embodiments 1 and 2, this embodiment 3 further takes into account the state adjustment process of the semi-solid material by construction personnel during the construction process, and provides a test method for the rheological properties of the semi-solid material.

[0115] Test with a rotational rheometer, including: before testing the rheological properties of the semi-solid material sample, use a rotational rheometer to pretreat the semi-solid material sample before batch scraping, and adjust the semi-solid material sample to be suitable for testing status.

[0116] In the above scheme, a test method for the rheological ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com