A kind of recycling equipment for NdFeB jet mill

A jet mill, NdFeB technology, applied in the field of mechanical processing, can solve the problems of increasing production costs, inconvenient operation, needing manual care, etc., and achieves the effects of energy saving and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following description is used to disclose the specific content of the present invention so that those skilled in the art can realize the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

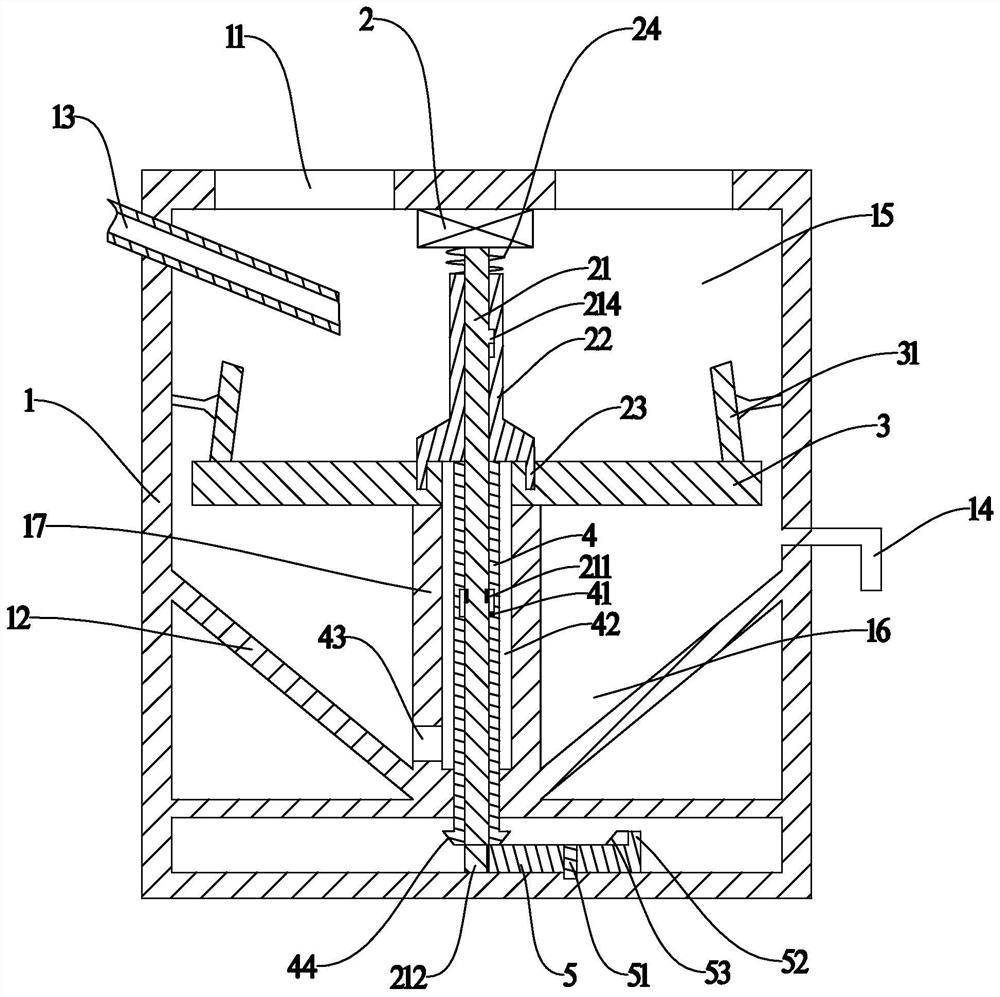

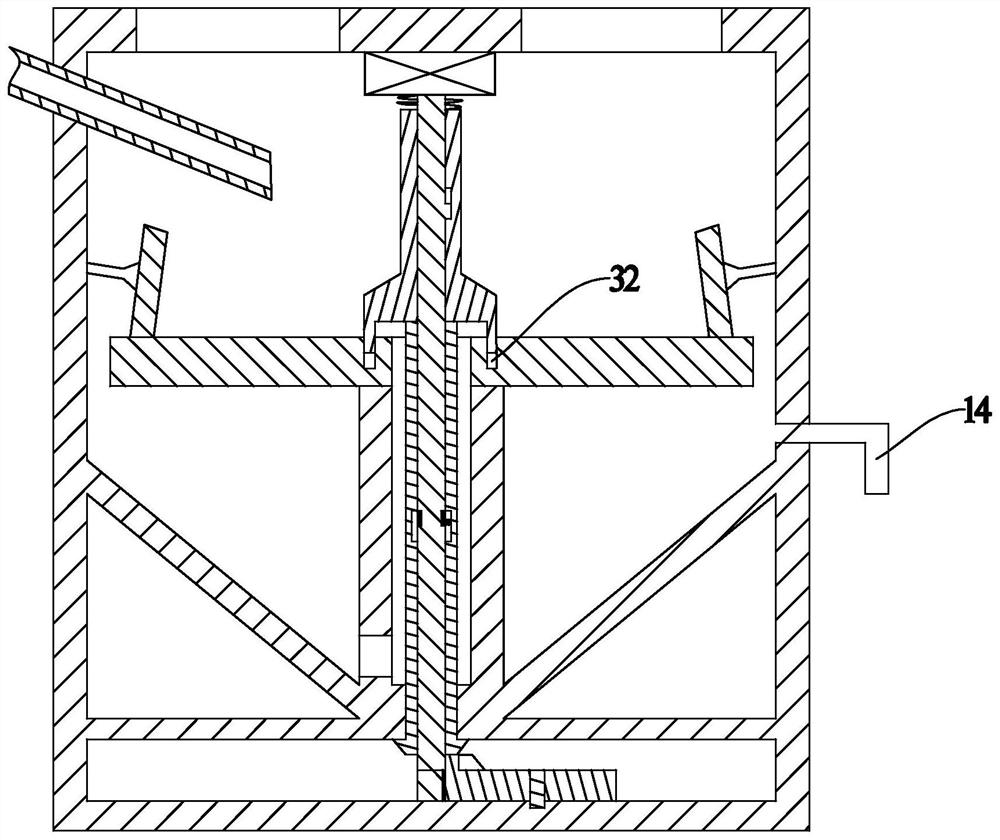

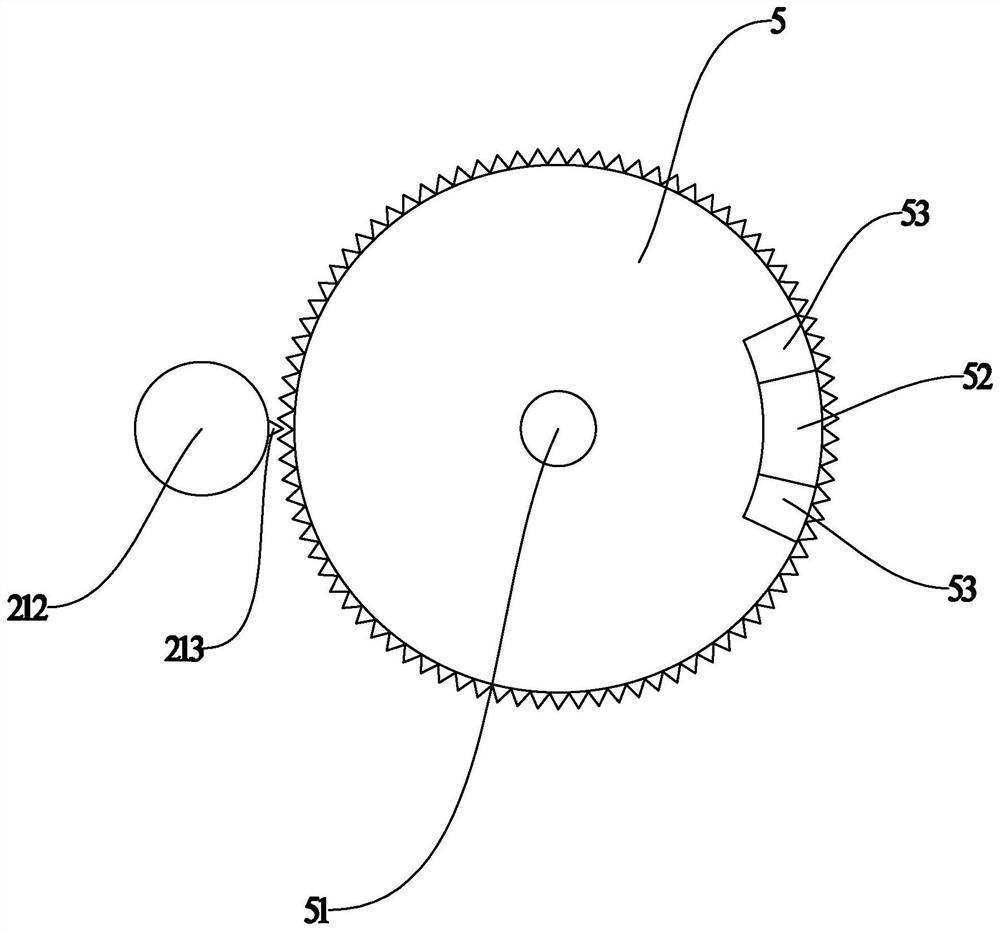

[0019] An embodiment of the present invention is a recycling device for an NdFeB jet mill, which includes a cover body 1 and a grinding part. The upper end of the cover body 1 is provided with a separation port 11, and the separation port is connected to the separation device of the next step process. The inside of the cover body 1 is a grinding chamber 15 and a V-shaped bucket 16 for collecting coarse materials. The grinding part is located at the connection between the grinding chamber 15 and the V-shaped bucket 16. The type bucket 16 is provided with an air inlet pipe 14 located below the grinding part, and the top of the cover body 1 is provided with a driving source 2, and the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com