Device used for cleaning and rotating infiltrated workpieces and applied to automatic infiltration line

A rotary device and impregnation technology, applied in liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low cleaning effect and achieve fully automatic production, continuous operation, stable reliability and high efficiency cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

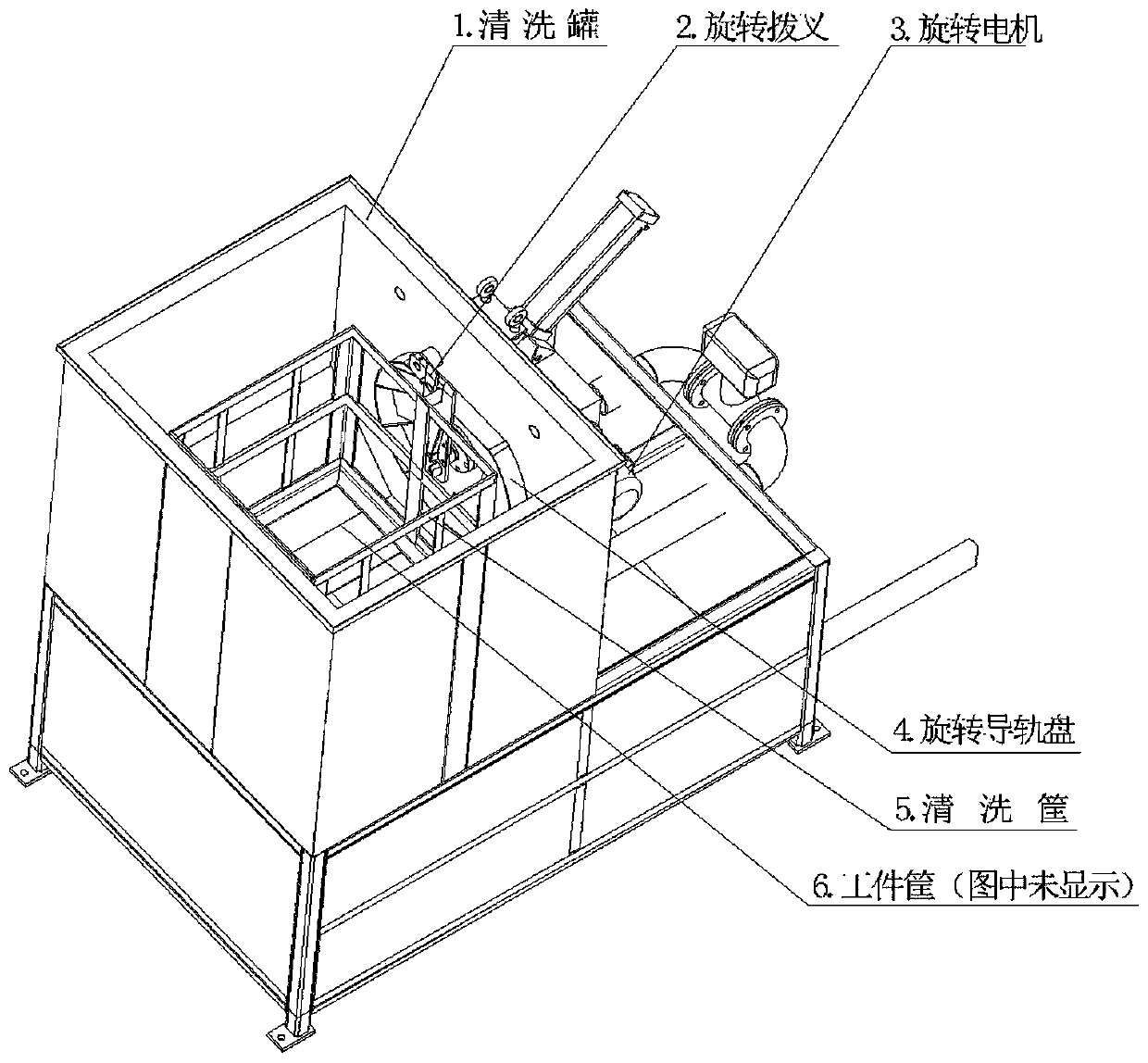

[0014] In the embodiment, the present invention discloses an automatic impregnation line cleaning rotary device for impregnated workpieces, such as figure 1 : 1. Cleaning tank; 2. Rotating fork; 3. Rotating motor; 4. Rotating guide disc; 5. Cleaning basket. The impregnated workpiece basket 6 is picked up and put into the cleaning basket 5 by using the power of the production line. The workpieces that need to be impregnated are contained in the workpiece basket 6 . The rotation of the rotary motor 3 drives the rotation of the rotary fork 2, the rotation of the rotary fork 2 drives the rotation of the cleaning basket 5, and the rotation of the cleaning basket 5 drives the rotation of the workpiece basket 6 for 360°. The rotating motor 3 is capable of forward and reverse rotation, and can drive the workpiece frame to rotate forward and reverse through 360°. The forward and reverse time and times can be controlled by the production line program. The cleaning tank 1 is filled wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com