Rotor sealing structure of internal mixer

A technology of rotor sealing and internal mixer, which is applied in the field of mechanical equipment sealing, can solve the problems of large influence of external factors and material leakage, etc., and achieve the effect of improving sealing effect, ensuring quality and realizing zero leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

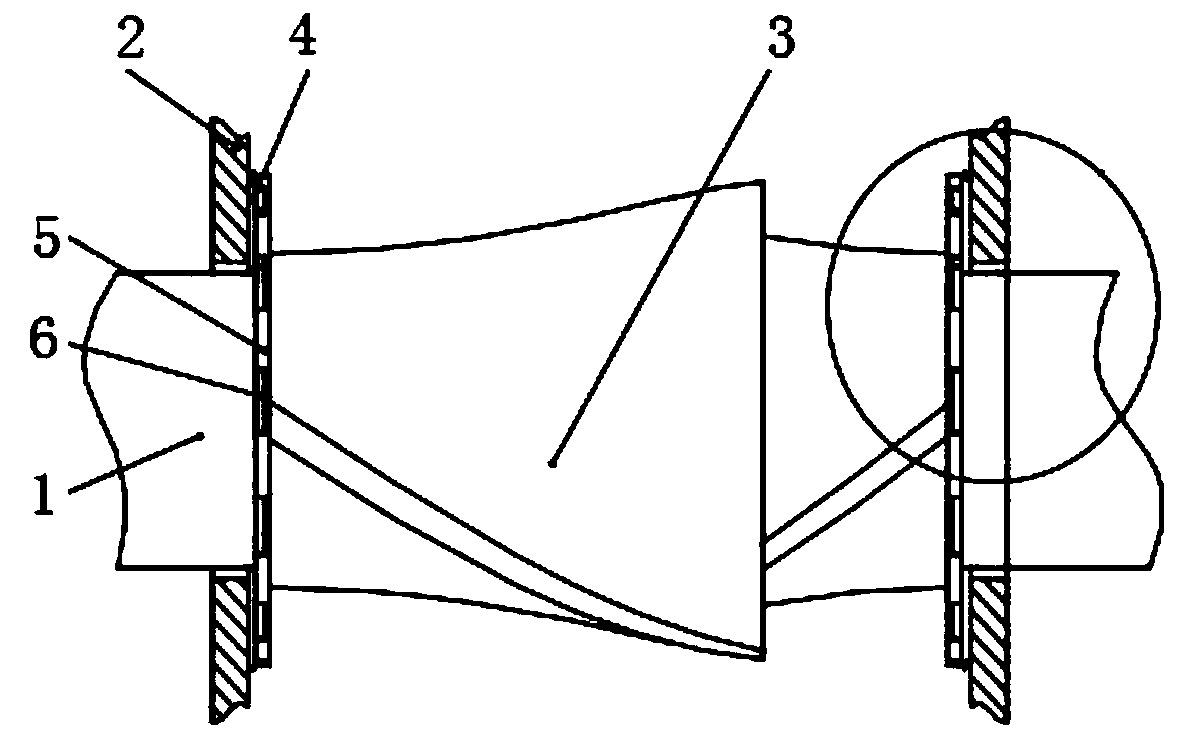

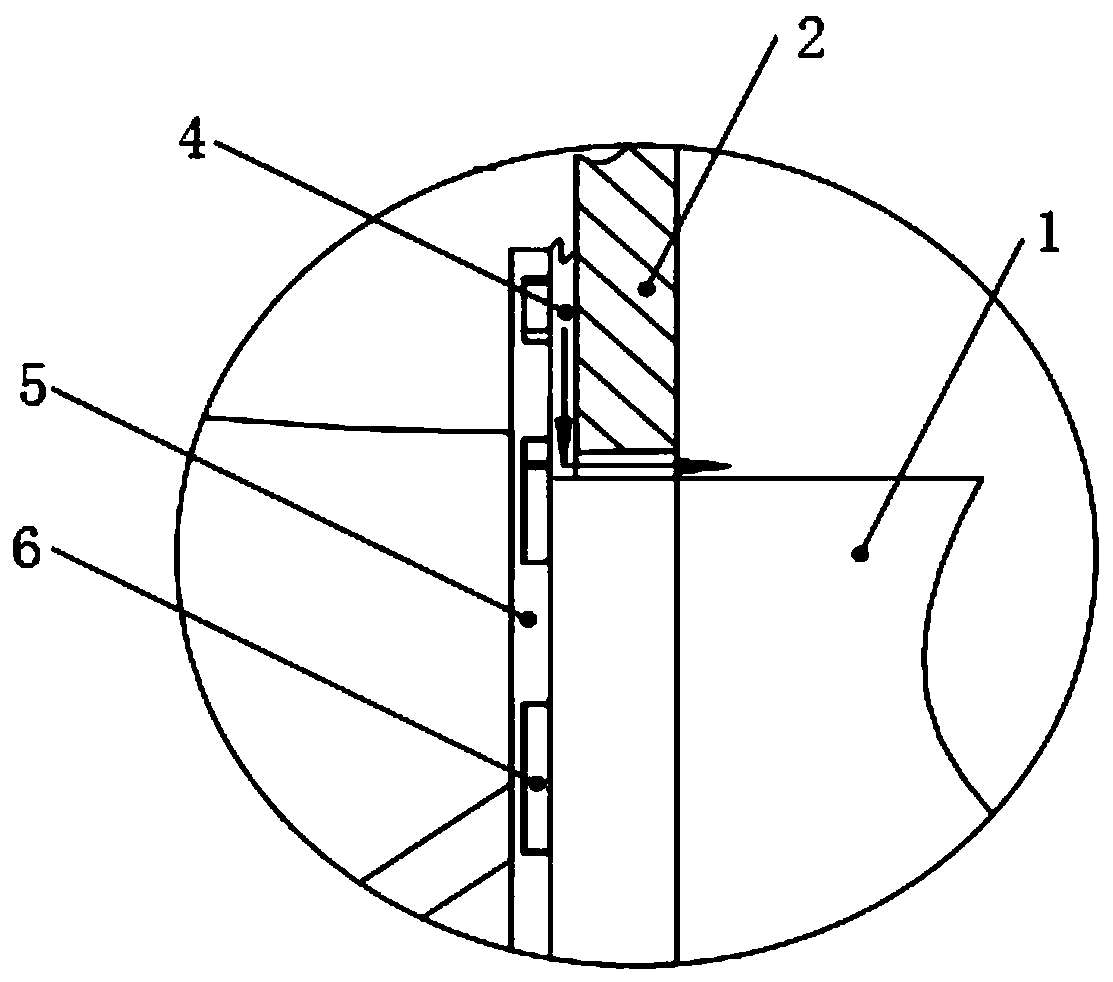

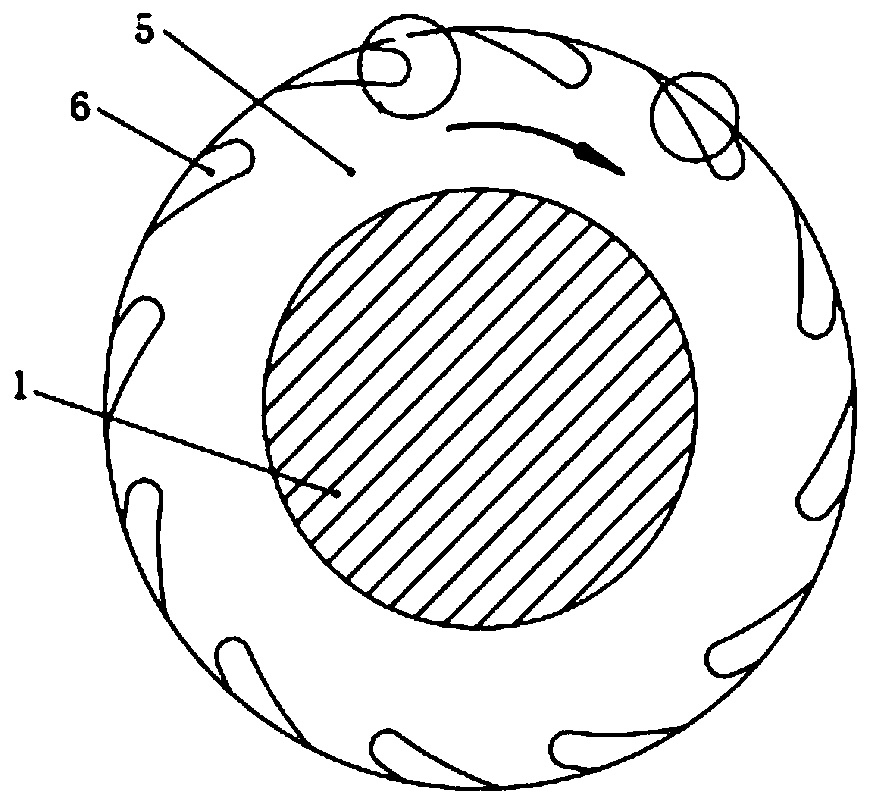

[0023] The main structure of the internal mixer rotor sealing structure involved in this embodiment includes a rotor shaft 1, a side wall 2, a rotor 3, a gap 4, a rotor working end face 5 and a spiral groove 6; both ends of the rotor shaft 1 protrude from the side wall 2, A rotor 3 is arranged on the rotor shaft 1 between the side walls 2 , there is a gap 4 between the side walls 2 and the rotor 3 , the end of the rotor 3 is provided with a rotor working end surface 5 , and a spiral groove 6 is opened on the rotor working end surface 5 .

[0024] The number of spiral grooves 6 involved in this embodiment is 12, which are equally spaced on the working end surface 5 of the rotor, which can effectively balance the radial force on the rotor 3. When the number of spiral grooves 6 is less than 12, the spiral grooves 6 The conveying volume of materials is small, and the sealing effect is not obvious. When the number of spiral grooves 6 is more than 22, the adjacent spiral grooves 6 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com