An icows-based cleaning spraying method for large crude oil storage tanks

A crude oil storage tank, large-scale technology, applied in the field of large-scale crude oil storage tank cleaning and spraying based on ICOWS, to achieve the effect of high efficiency and shortening cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

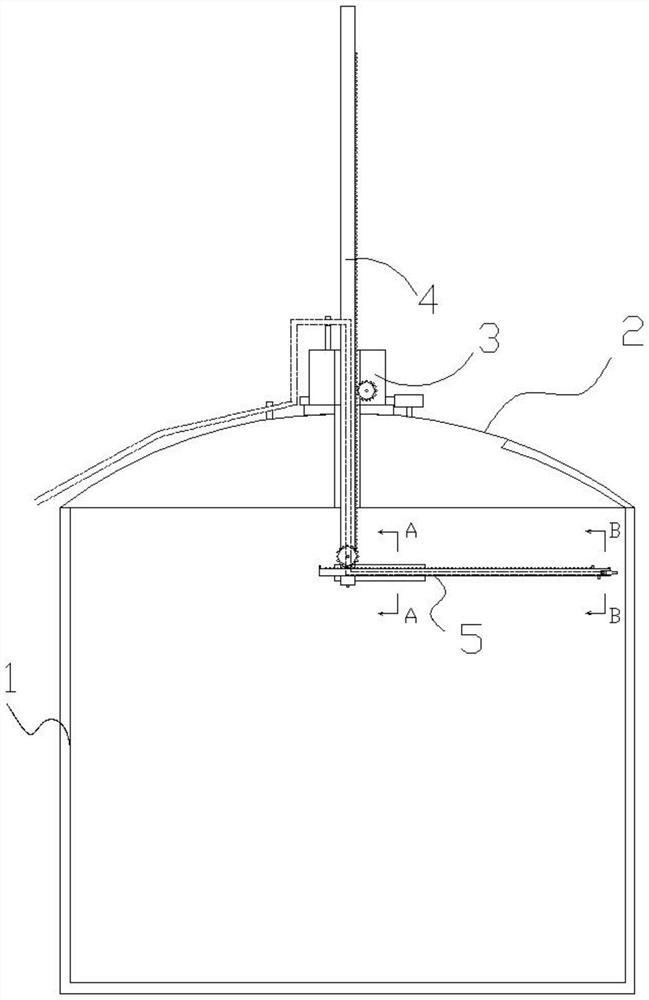

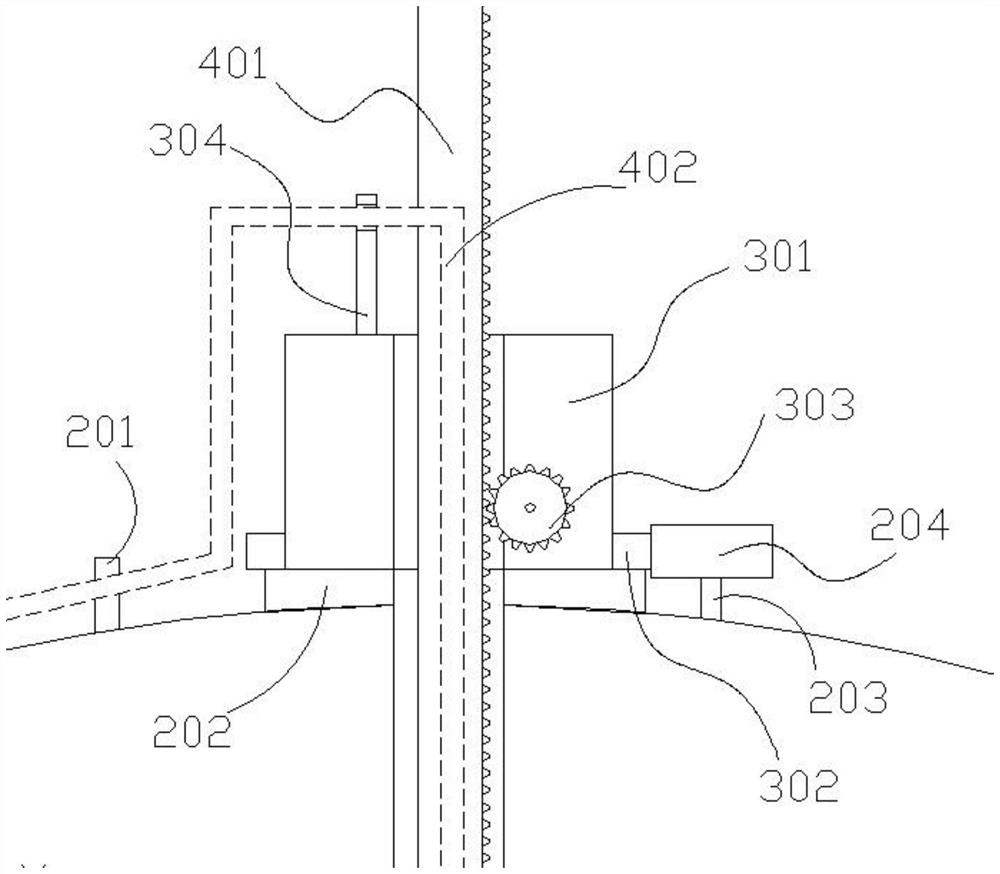

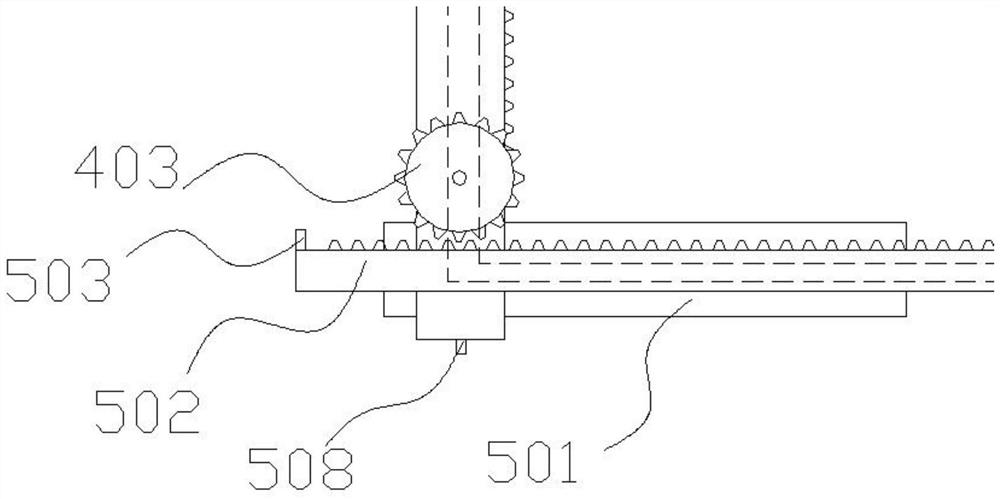

[0055] like Figure 1-Figure 6 , shown in 13, a kind of large-scale crude oil storage tank cleaning injection device based on ICOWS, is used for the cleaning of large-scale oil tank, as 100,000 cubic meters of oil tank, and oil tank comprises tank body 1 and top cover 2, and described top cover 2 It is a semi-ellipsoidal structure, the middle part of the top cover 2 is provided with a central cover 205, and the side is provided with a side cover 206, and the central cover 205 is a detachable structure, which is connected and sealed with the main body of the top cover 2 by thread or cover , form a round hole after removal, the diameter of the round hole is 50-70cm; the cleaning spray device includes a rotating mechanism 3, a cleaning system longitudinal movement module 4 and a cleaning system lateral movement module 5, and the rotating mechanism 3, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com