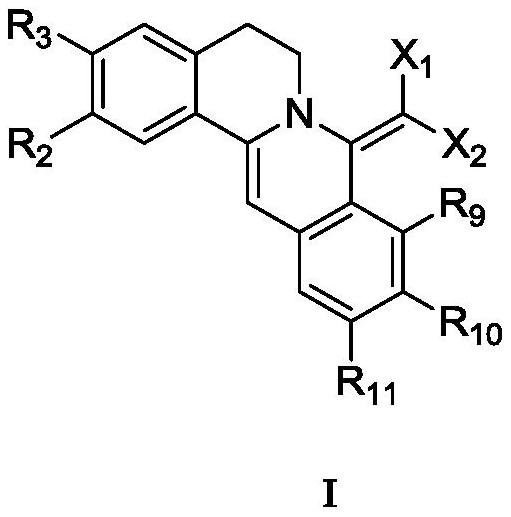

8-dihalogenomethylene dihydroberberine type compound and its anti-infection and anti-inflammation application

A technology of dihalomethylenedihydroberberine and methylenedioxy is applied in the application field of preparing anti-microbial infection and anti-inflammatory products, and can solve the problems affecting pharmacological effects, structural changes, and chemical structure instability. and other problems, to achieve significant medicinal efficacy and safety, and the application prospect is significant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

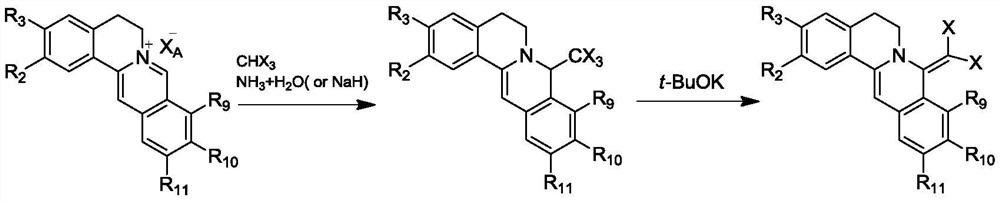

Method used

Image

Examples

experiment example (1

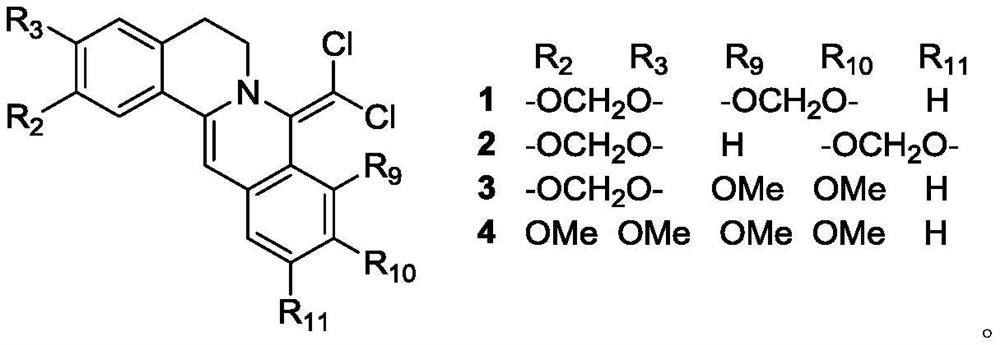

[0046] Experimental example (1) Preparation process and structural identification data of compound 1

[0047] Coptis alkaloid hydrochloride (2.0 g, 5.62 mmol) was dissolved in 200 mL of chloroform-methanol (3:1) mixed solvent in a reaction flask, 24 mL of concentrated ammonia water was added, and the reaction was stirred at room temperature for 24 h, and then the chloroform layer was separated, and The chloroform layer was washed twice with water, with anhydrous MgSO 4 After drying, filtration; the filtrate was evaporated to dryness, and the residual crude product obtained was purified by silica gel column chromatography, eluted with dichloromethane, and the eluate was concentrated to obtain 617 mg of 8-trichloromethyldihydrocoptidine as a pale yellow solid, yield 25.0%. 1 H NMR (500MHz, CDCl 3 )δ: 2.63–2.78 (m, 1H, NCH 2 C H 2 ),3.35(m,1H,NCH 2 C H 2 ),3.71(m,1H,NC H 2 CH 2 ),3.78-3.90(m,1H,NC H 2 CH 2 ),5.42(s,1H,CH-CCl 3 ),5.91(br,1H,OCH 2 O),5.95(br,2H,OCH ...

experiment example (2

[0048] Experimental example (2) Preparation process and structural identification data of compound 2

[0049] Dissolve isoplastin hydrochloride (1.0 g, 2.81 mmol) in 80 ml of chloroform in a reaction flask, add NaH (450 mg, 18.75 mmol) under ice, slowly warm up to room temperature and stir the reaction for 24 h, then concentrate the reaction solution under reduced pressure to A residue was obtained; ethyl acetate was added to the residue first, followed by an appropriate amount of purified water, extracted with ethyl acetate for 3 times, combined with the ethyl acetate extracts, and washed with anhydrous MgSO 4 Dry, filter, and evaporate the filtrate to dryness. The obtained crude product was purified by silica gel column chromatography, eluted with petroleum ether / ethyl acetate (3 / 1, v / v), and the eluate was concentrated to obtain 8-trichloromethyldihydrogen Isoptyxine yellow solid 995mg, yield 80.7%. 1 HNMR (500MHz, CDCl 3 )δ: 2.68(d, J=15.5Hz, 1H, NCH 2 C H 2 ),3.35-3....

experiment example (3

[0050] Experimental example (3) Preparation process and structural identification data of compound 3

[0051] Berberine hydrochloride (2.0 g, 5.38 mmol) was dissolved in 60 ml of chloroform in a reaction flask, 24 ml of concentrated ammonia water was added, and the reaction was stirred at room temperature for 24 h, then the chloroform layer was separated, and the chloroform solution was washed with water twice, with Anhydrous MgSO 4 The chloroform solution was dried and filtered, and the filtrate was evaporated to dryness to obtain a residue; the residue was separated and purified by silica gel column chromatography, eluted with dichloromethane, and the eluent was evaporated to dryness to obtain 8-trichloromethyldihydrobarberry Alkali pale yellow solid 1.775g, yield 78.9%. 1 H NMR (500MHz, CDCl 3 )δ: 2.73(d, J=15.5Hz, 1H, NCH 2 C H 2 ),3.33(m,1H,NCH 2 C H 2 ),3.71(m,1H,NC H 2 CH 2 ),3.87(ov,4H,ArOCH 3 ,NC H 2 CH 2 ),3.94(s,3H,ArOCH 3 ),5.65(s,1H,CH-CCl 3 ),5.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com