Fuse mounting device

A technology for installing devices and fuses, applied in emergency protection devices, electrical components, circuits, etc., can solve problems such as loose conductive sheets, affecting power-off protection of fuses, and poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

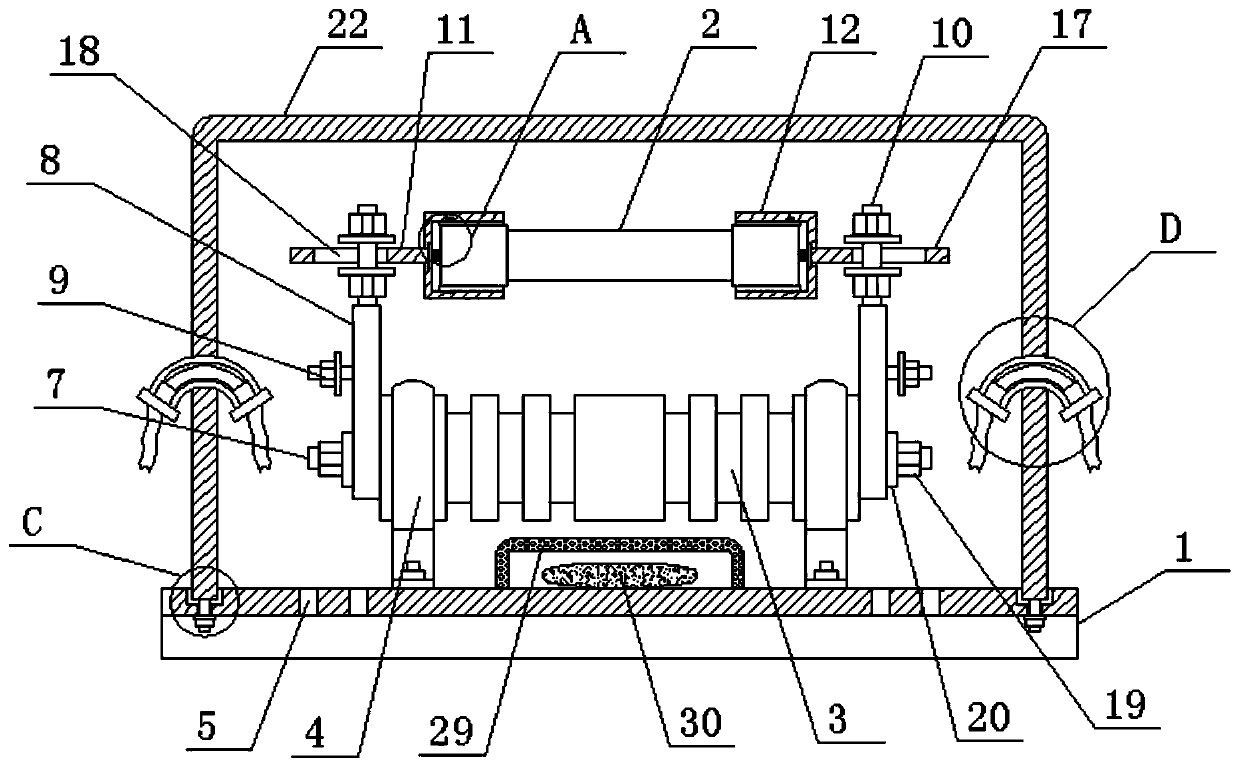

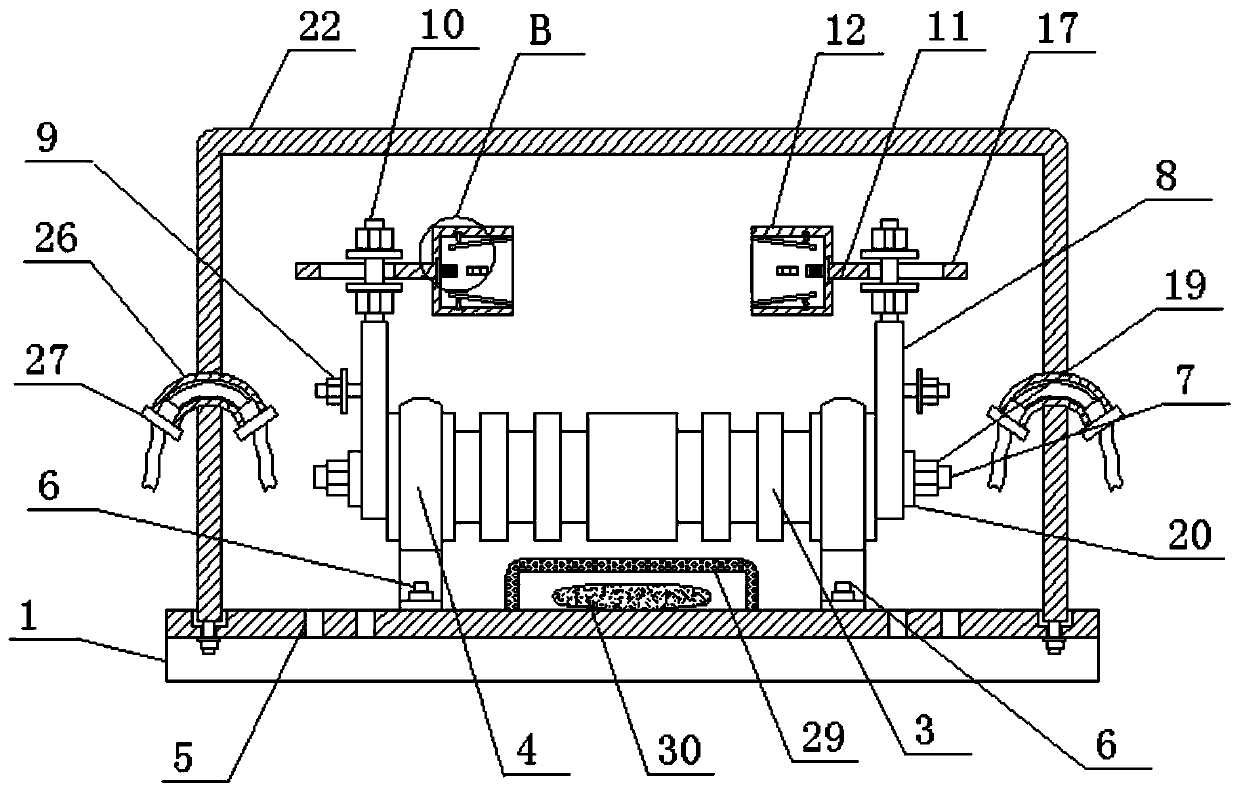

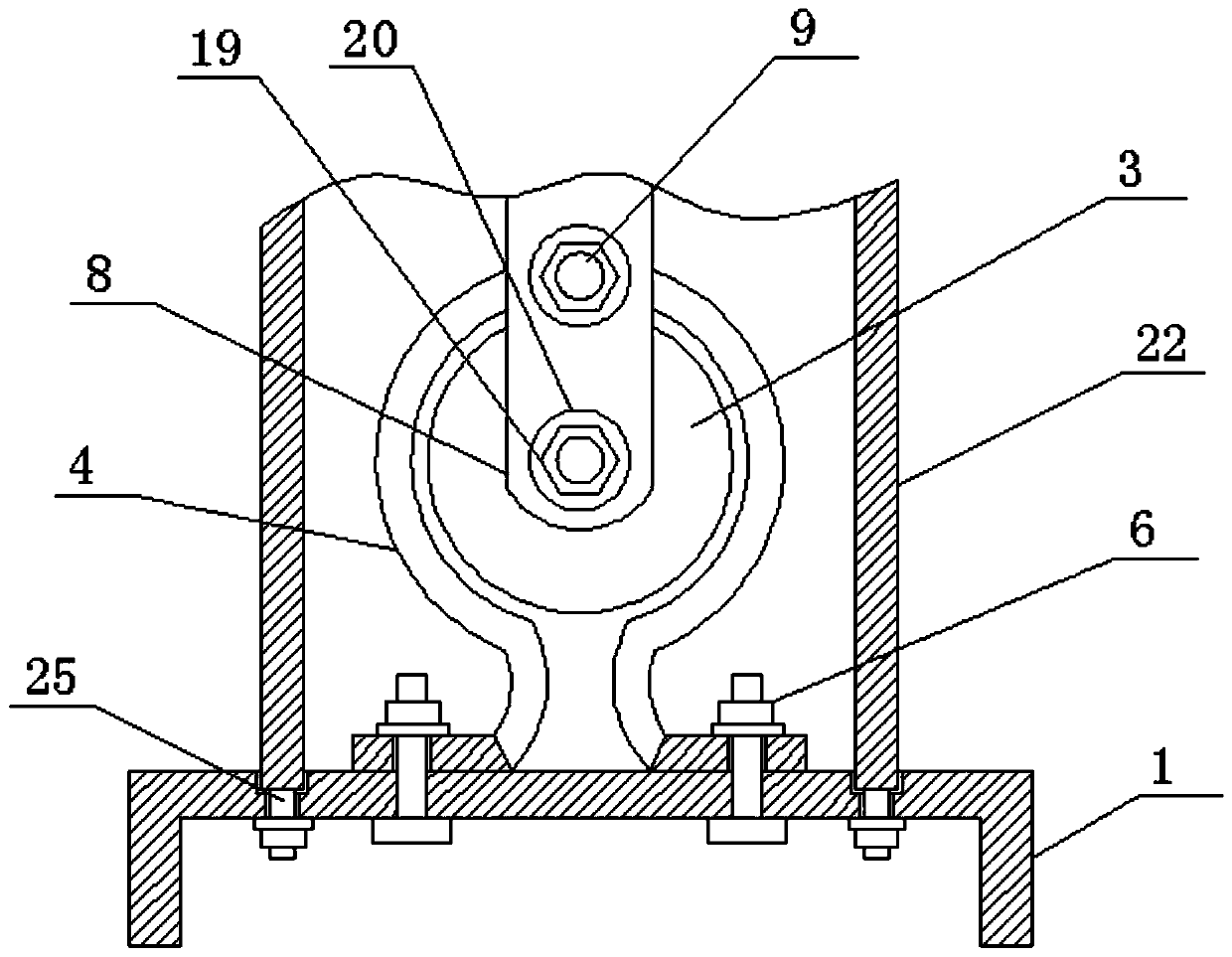

[0033] according to Figure 1-10 A fuse installation device shown includes a base 1, a fuse 2 and a ceramic insulator 3, the surfaces of both ends of the ceramic insulator 3 are provided with clamps 4, and the base 1 is provided with several sets of clamps near the surfaces of both ends. The clamp 4 is installed with a mounting hole 5, and a fastening bolt 6 is arranged between the clamp 4 and the mounting hole 5. Both ends of the ceramic insulator 3 are provided with connecting screws 7, and the surfaces of the two connecting screws 7 are A conductive connection plate 8 is sleeved, and a terminal 9 is provided on one side of the conductive connection plate 8, and a fixing screw 10 is fixedly connected to one end of the top of the conductive connection plate 8, and a fuse is arranged between the two fixing screws 10 The fixing device 11, by using two nuts 19 to fix the fuse fixing device 11 on the fixing screw 10, is beneficial to change the height between the fuse 2 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com