Method for adjusting the rotational speed of a centrifugal pump

A centrifugal pump, speed technology, applied in pump control, non-variable-capacity pumps, machines/engines, etc., to solve problems such as adjustment that cannot lead to satisfactory results, tedious adjustment outdated, and changes in mathematical relationships.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

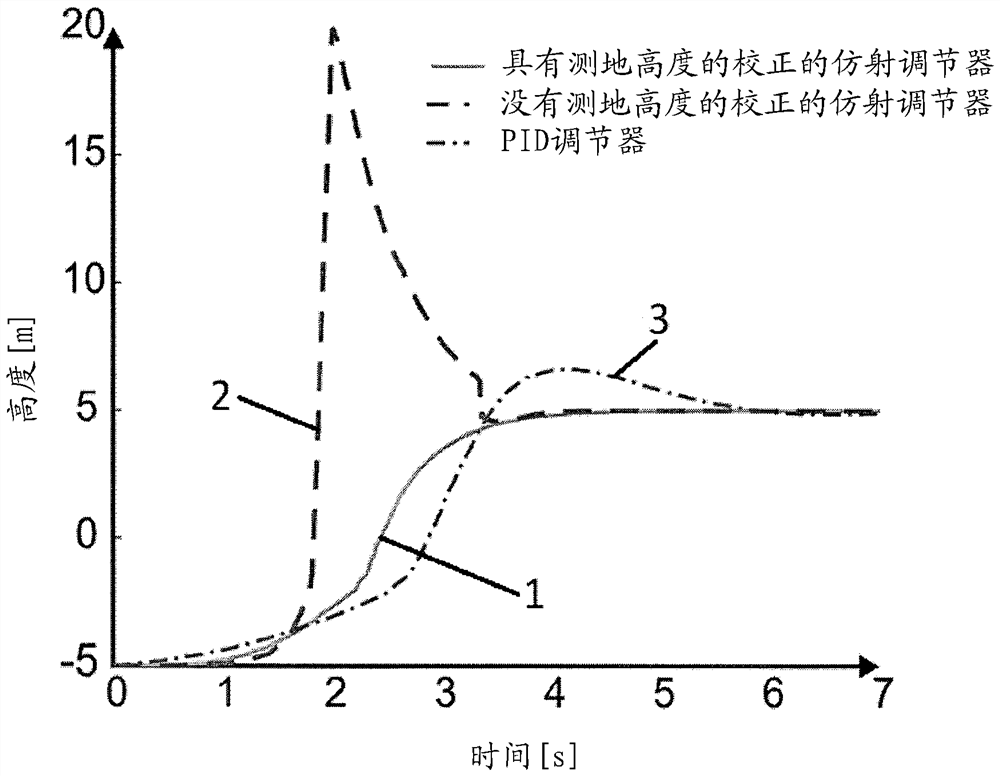

[0024] The core idea of the invention is to use a new type of regulator for speed regulation of a centrifugal pump. Unlike the prior art, it is proposed not to use a PI or PID controller at all, but instead to use a so-called affine controller, which uses the affine law to determine the manipulated value / target value and is therefore based on the rotational speed of the centrifugal pump Power of two relationship with the resulting delivery height.

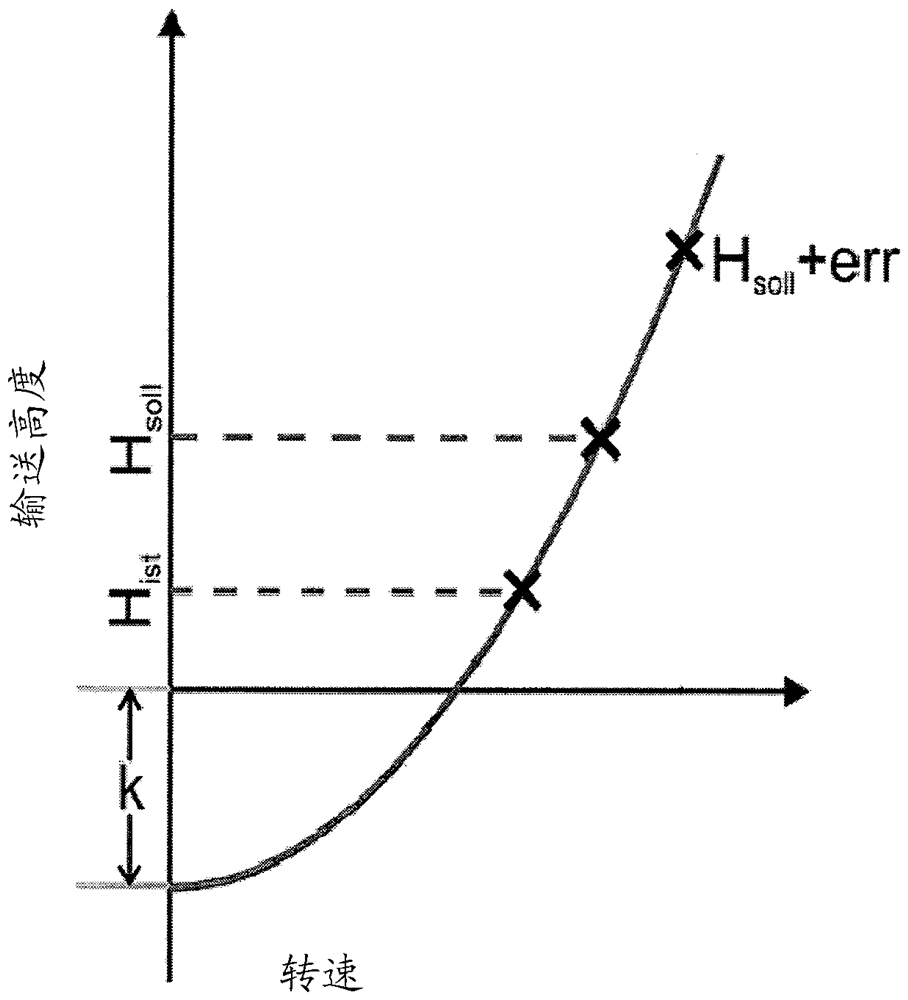

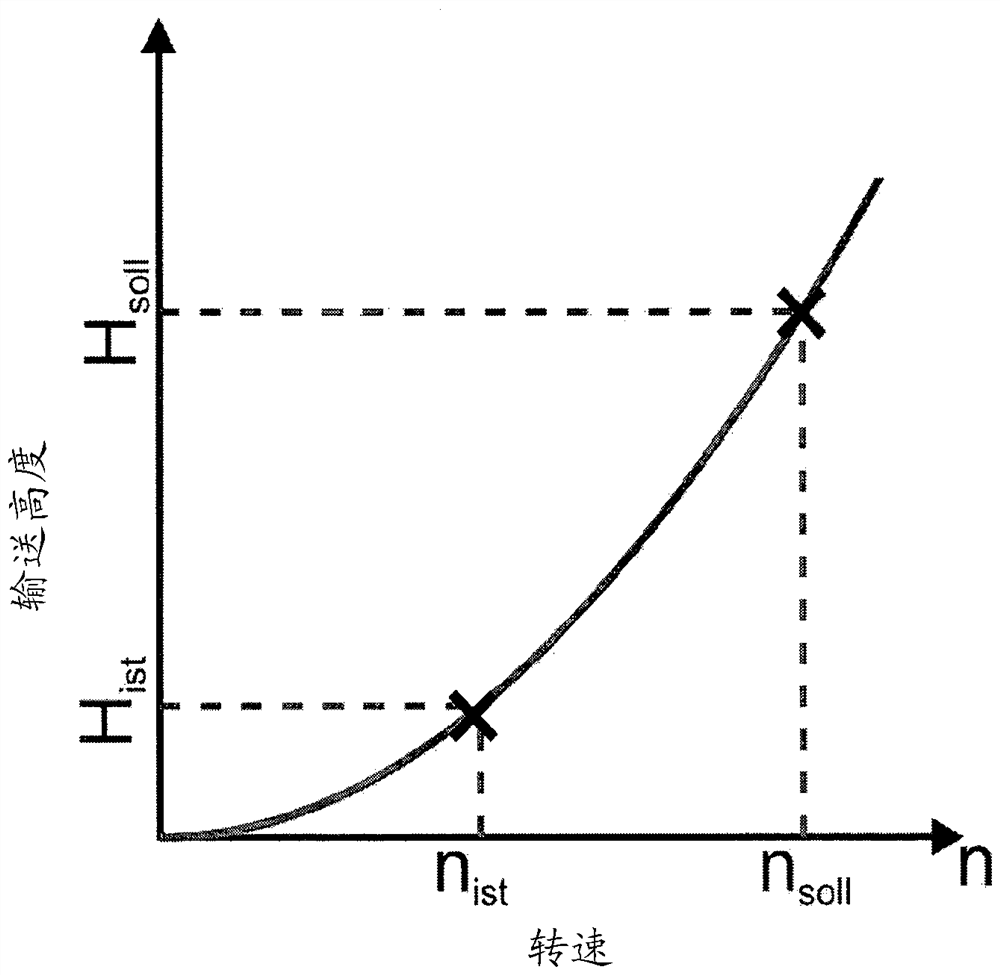

[0025] For a description of the functionality of this affine regulator, see figure 1 . The delivery height is plotted against the set pump rotational speed in the diagram representation. The diagram shows here in detail the quadratic relationship between the conveying height H and the rotational speed n, which can be expressed by the equation

[0026] (Equation 1)

[0027] to describe. also, figure 1 exemplarily shows the actual-rotational speed n ist and target-speed n soll . Due to the relationship of the second pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com