A test method for optimization and adjustment of boiler load control in generating units

A boiler load and generator set technology, applied in control systems, steam generation, lighting and heating equipment, etc., can solve the problem of large delay and large inertia characteristics that cannot compensate for the nonlinear characteristics of the boiler, and can not adapt to the rapid response of the steam turbine generator set to external loads. Changes, the boiler load control effect is not very ideal, etc., to achieve the effect of suppressing large delays, improving the ability of load changes, and reducing the range of changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

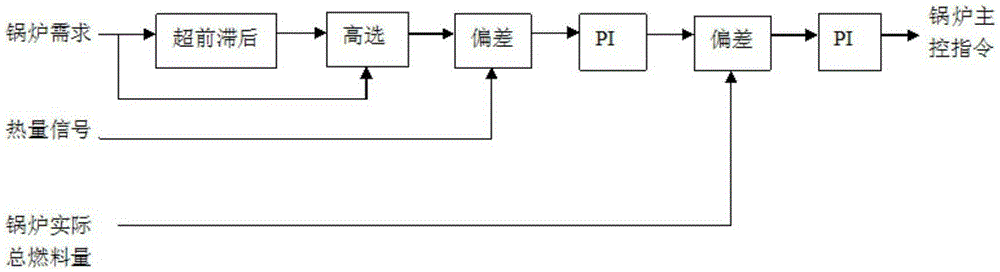

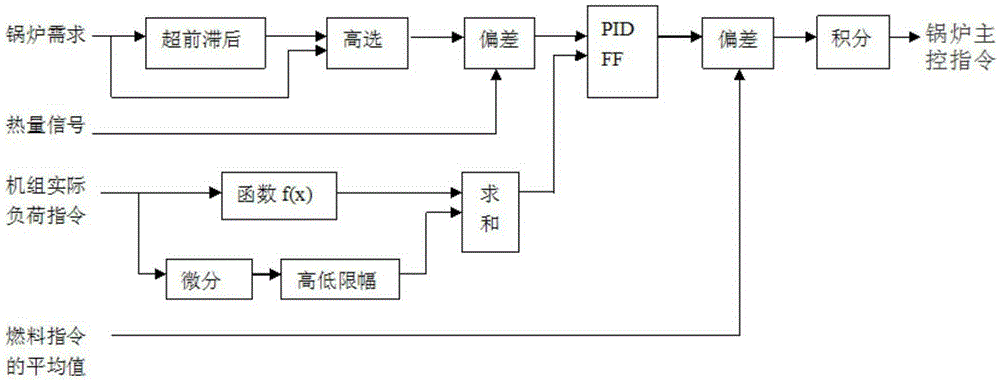

[0029] A test method for optimization and adjustment of boiler load control for generator sets, such as figure 2 shown, including the following steps:

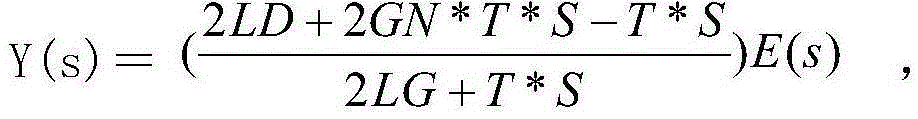

[0030] (1) After the boiler demand command is processed by the lead / lag function module, it is then input to the high-selection module for processing; wherein, a dynamic lead / lag correction link is introduced into the lead / lag function module to generate dynamic overshoot to achieve shortening The effect of delay time, reducing dynamic parameter fluctuations and improving the response speed of load changes, the dynamic lead lag correction effect should not be too strong,

[0031] Limiting treatment should be done, otherwise the coal quantity fluctuates greatl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com