Modular assembly type building wallboard connecting structure

A prefabricated and building wall technology, which is applied in building components, building structures, construction, etc., can solve the problems of excessive materials, inconvenient disassembly, and complicated splicing, and achieves wide application range, convenient installation and disassembly, and uniform component specifications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

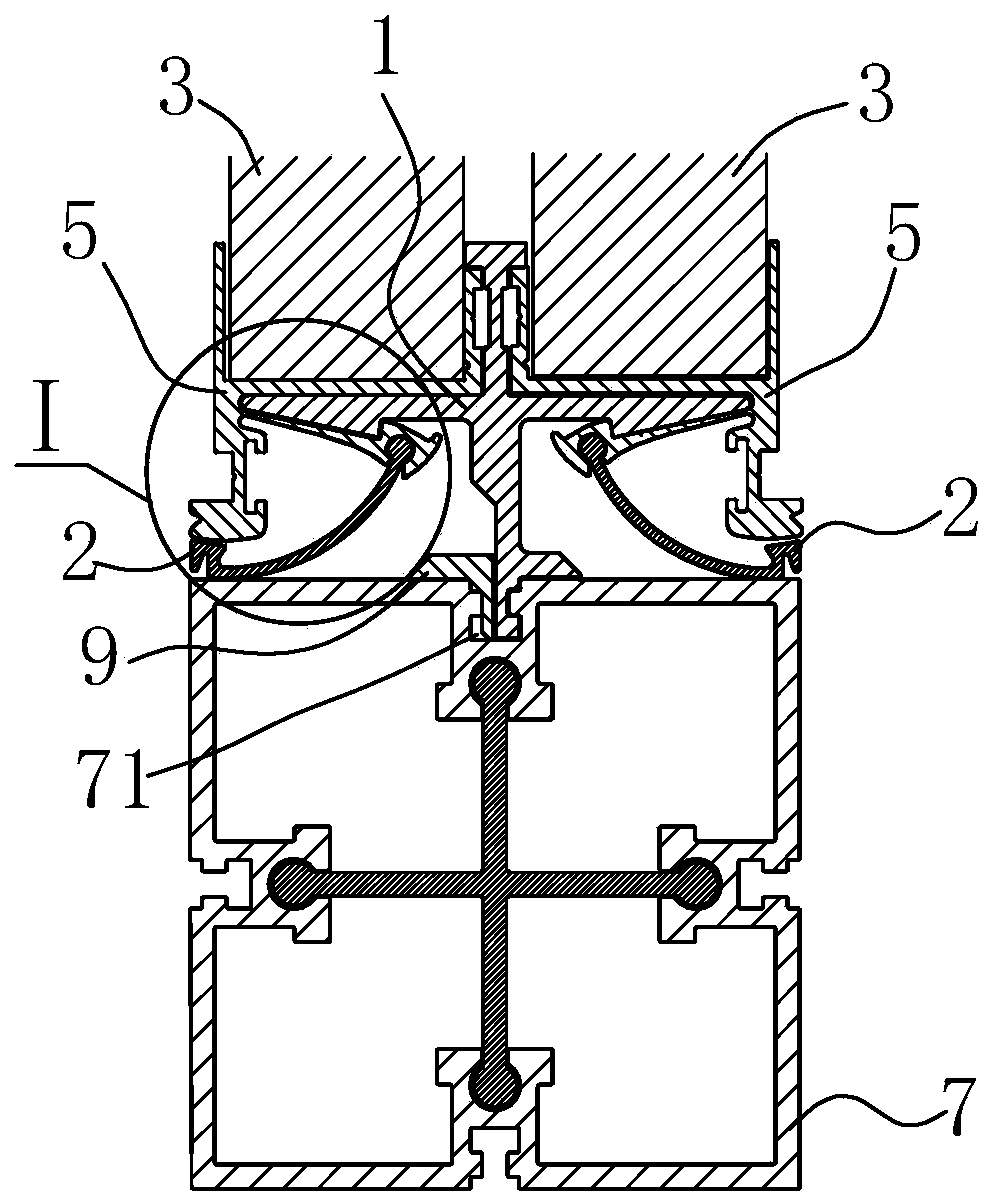

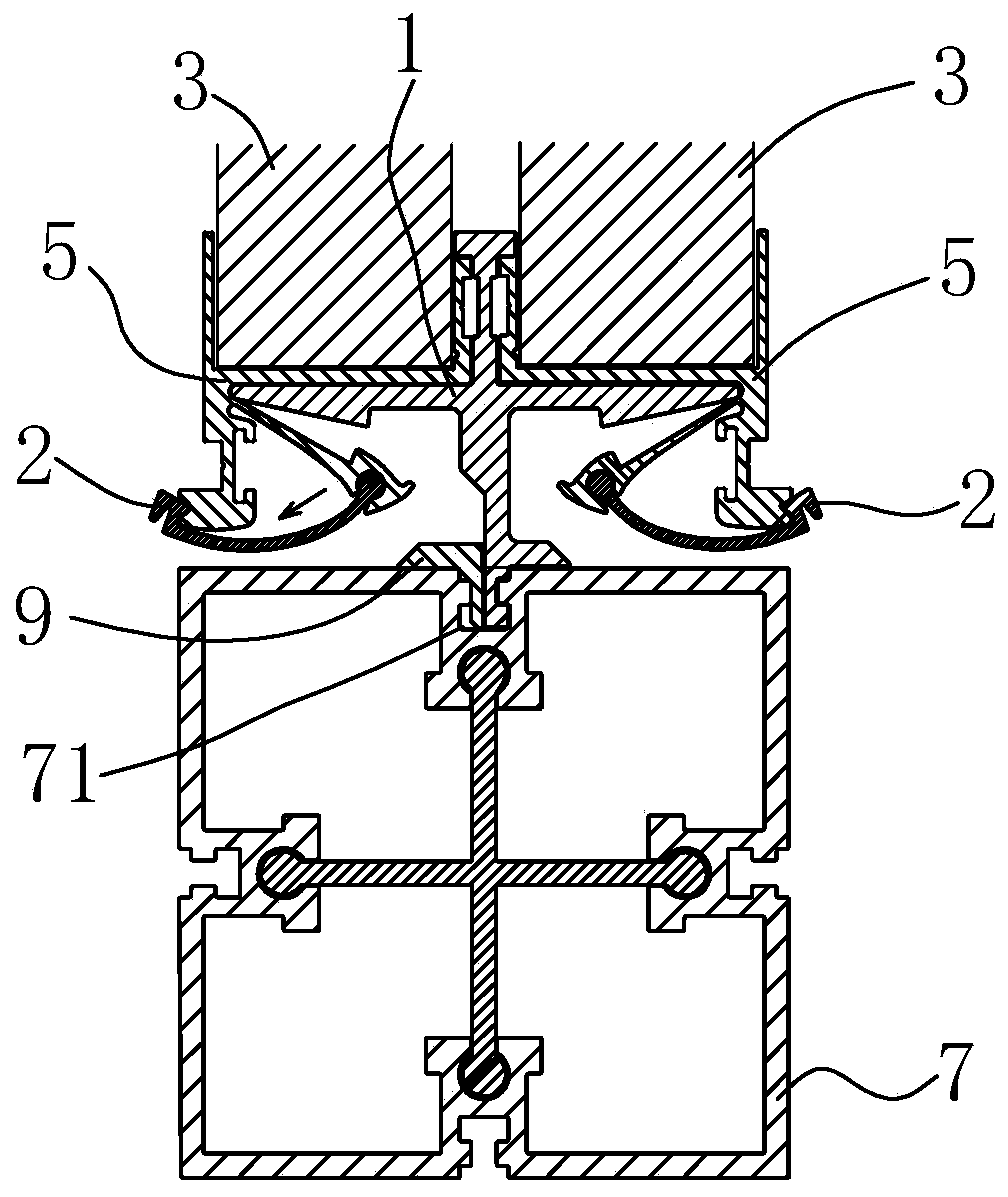

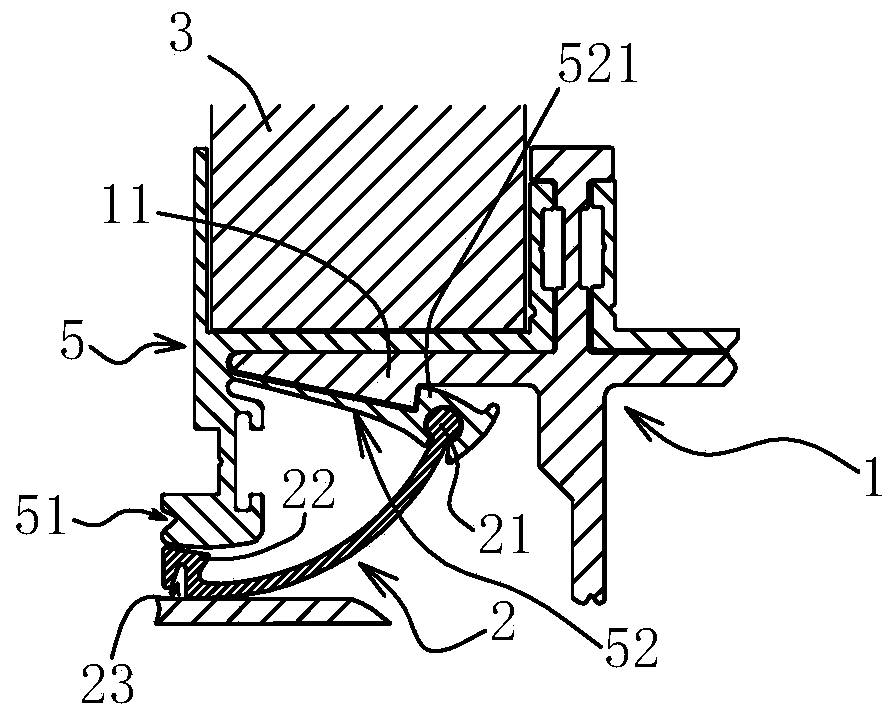

[0026] Such as figure 1 , figure 2 with image 3 Commonly shown is a modular assembled building wall panel connection structure, and the wall panel device is installed on the frame 7 through the connection device.

[0027] Such as Figure 4 As shown, the wall panel device includes a wall panel body 3 and a plurality of wall panel frames connected together in sequence, the wall panel body 3 is arranged in the area surrounded by the wall panel frames, and the wall panel frames The corners are fixed together by L-shaped connecting strips 6, and the wall panel body is preferably a thermal insulation board or a heat insulation board.

[0028] Such as figure 1 , figure 2 with image 3 Commonly shown, the wall panel frame includes a wall panel installation strip 5 and a tongue support strip 2, and the body of the wall panel installation strip 5 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com