Flash evaporator

A flash evaporator and flash evaporation technology, which is applied in steam boilers, steam generation, lighting and heating equipment, etc., can solve the problems of the temperature not meeting the heating requirements, reducing the total heat recovered, and improving the flash evaporation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

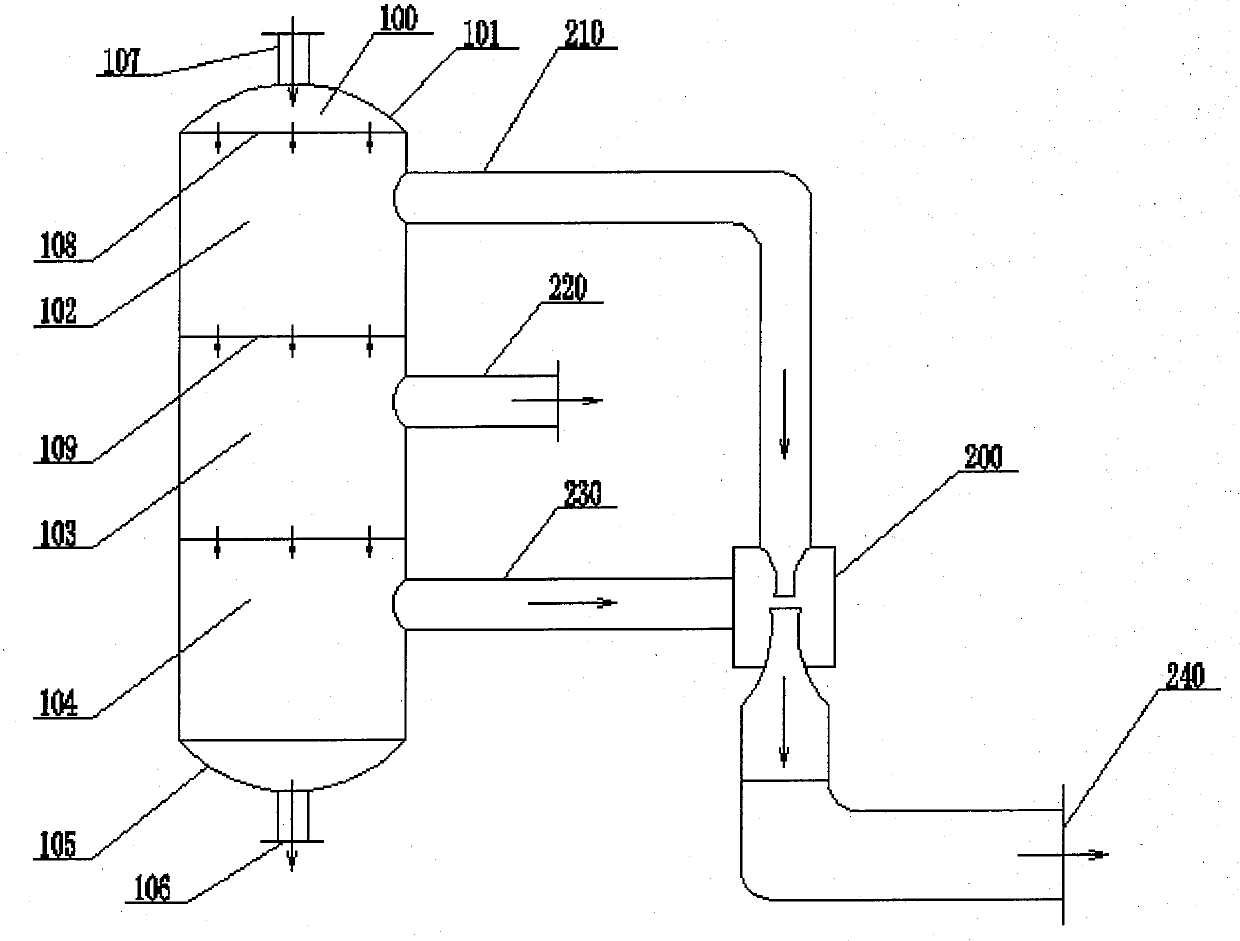

[0016] figure 1 A general diagram of an embodiment of a flash evaporator of the present invention is given.

[0017] An embodiment of a flash evaporator of the present invention, its overall structure 100 includes: a water inlet 107, an upper head 101, a water shower plate 108, a first flash chamber 102, a cylinder 109, a second flash chamber 103, a second Three flash chambers 104 , lower head 105 , water outlet 106 , first steam outlet pipe 210 , second steam outlet pipe 220 , third steam outlet pipe 230 , steam injector 200 , and injector outlet 240 .

[0018] A kind of flash evaporator embodiment of the present invention is a three-stage flash evaporator, placed upright, and its specific working process is

[0019] Industrial waste hot water enters from the upper water inlet 107 of the flash evaporator, passes through the space between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com