A Reliable Hub Chuck

A kind of hub and reliable technology, which is applied in the field of machine manufacturing, can solve the problems of complex movement trajectories of the jaws, increase the outer size of the chuck, and low reliability of loading, unloading and opening, and achieves reduced range of motion, reduced weight, and good rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

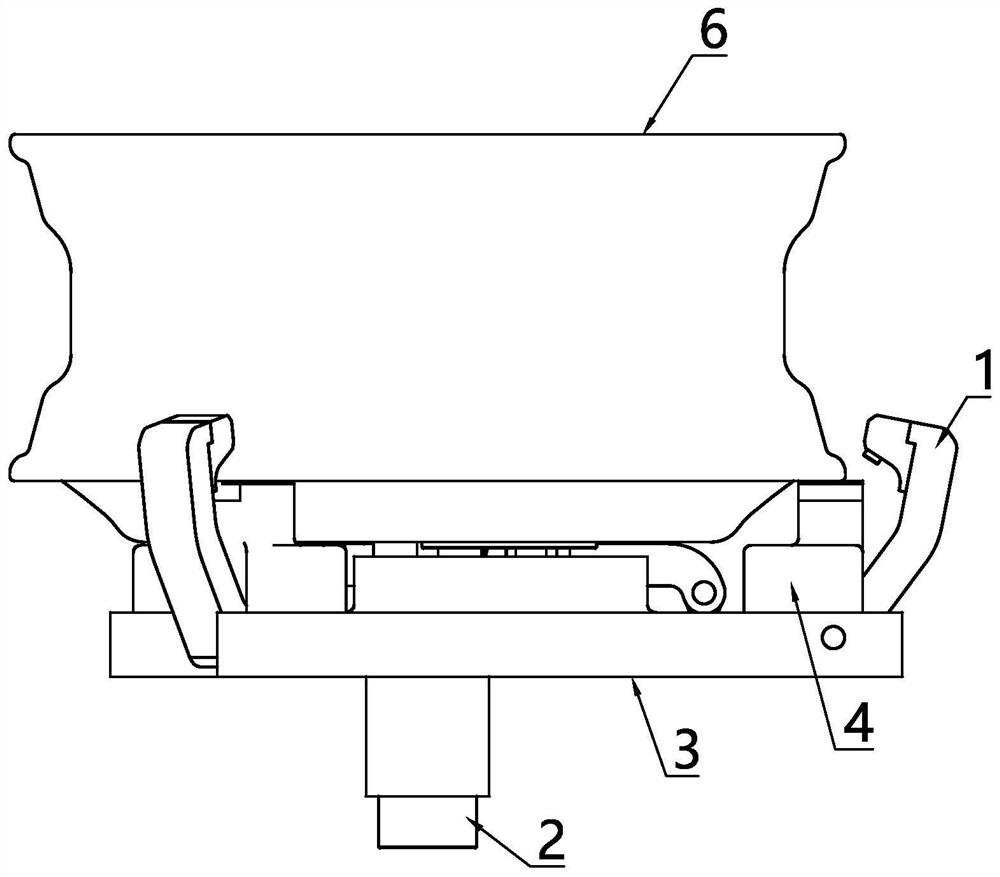

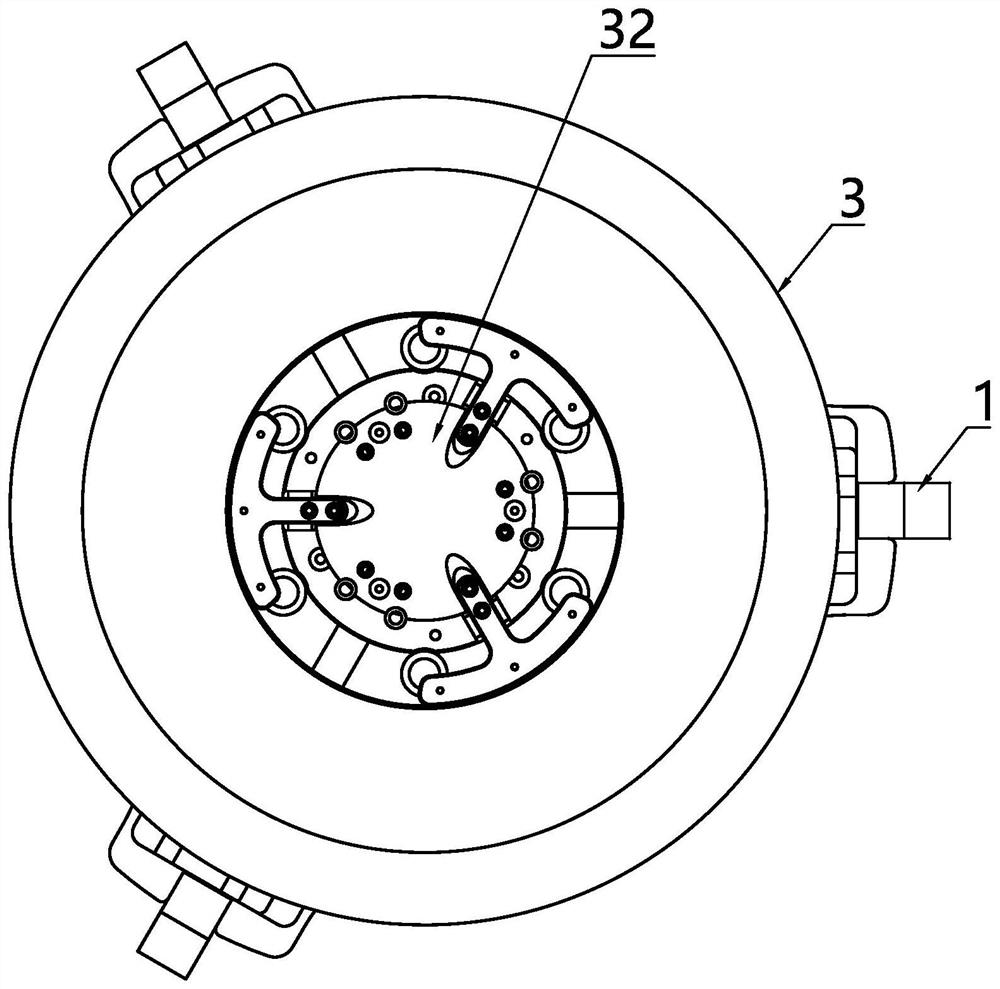

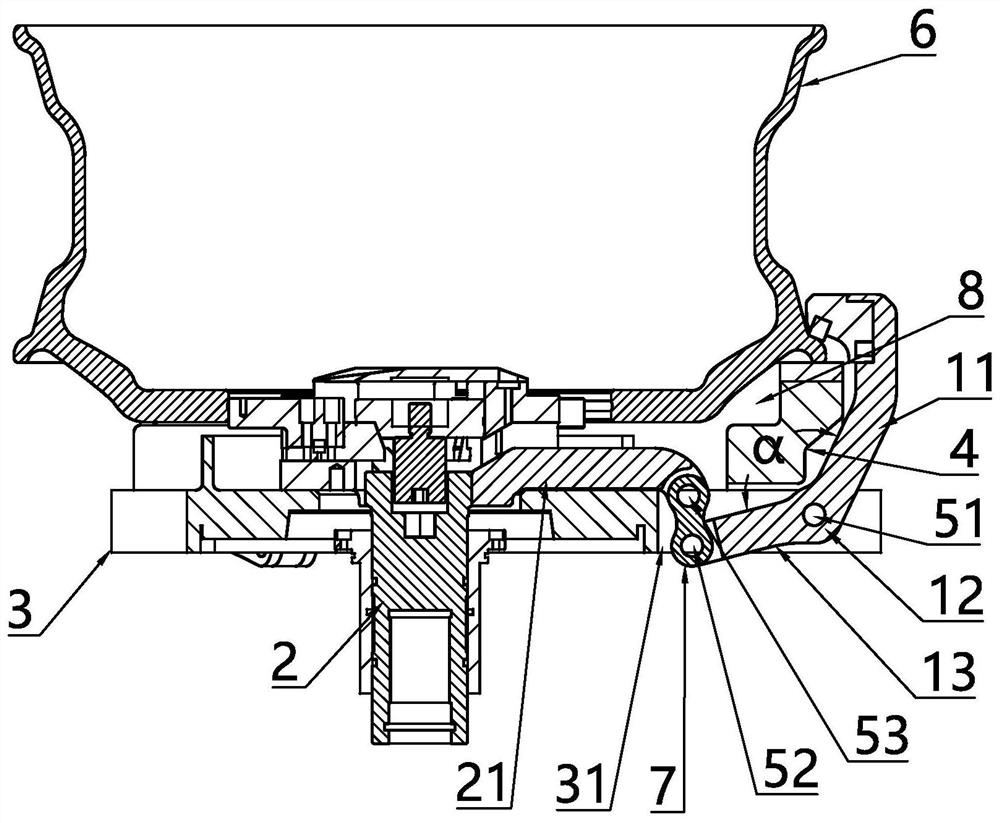

[0021] The present invention provides a reliable hub chuck such as Figure 1 to Figure 4 As shown, it includes a claw 1 and a moving sleeve 2 with a moving rod 21. The driving device drives the moving sleeve 2 to reciprocate along the axis of the main shaft. The outer sleeve of the moving sleeve 2 is provided with a base plate 3 that rotates synchronously with the main shaft. An end face locator 4 for the axial positioning of the hub 6 is provided, and the claw 1 includes a gripping arm 11, a connecting arm 13 and a connecting portion 12 connecting the gripping arm 11 and the connecting arm 13, and the gripping arm 11 compresses the wheel hub 6 on the The hub 6 is clamped on the end surface positioning member 4 , the connecting portion 12 is hinged to the base plate 3 through the first rotating shaft 51 , and the connecting arm 13 is movably connected to the moving rod 21 .

[0022] The reciprocating moving sleeve 2 drives the grasping arm 11 to rotate around the first rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com