A kind of anti-scratch semiconductor ingot point opening processing equipment

A technology for processing equipment and semiconductors, used in stone processing equipment, fine work equipment, manufacturing tools, etc., and can solve problems such as hard material, equipment damage, and staff injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Append figure 1 Attachment Figure 7 Looking:

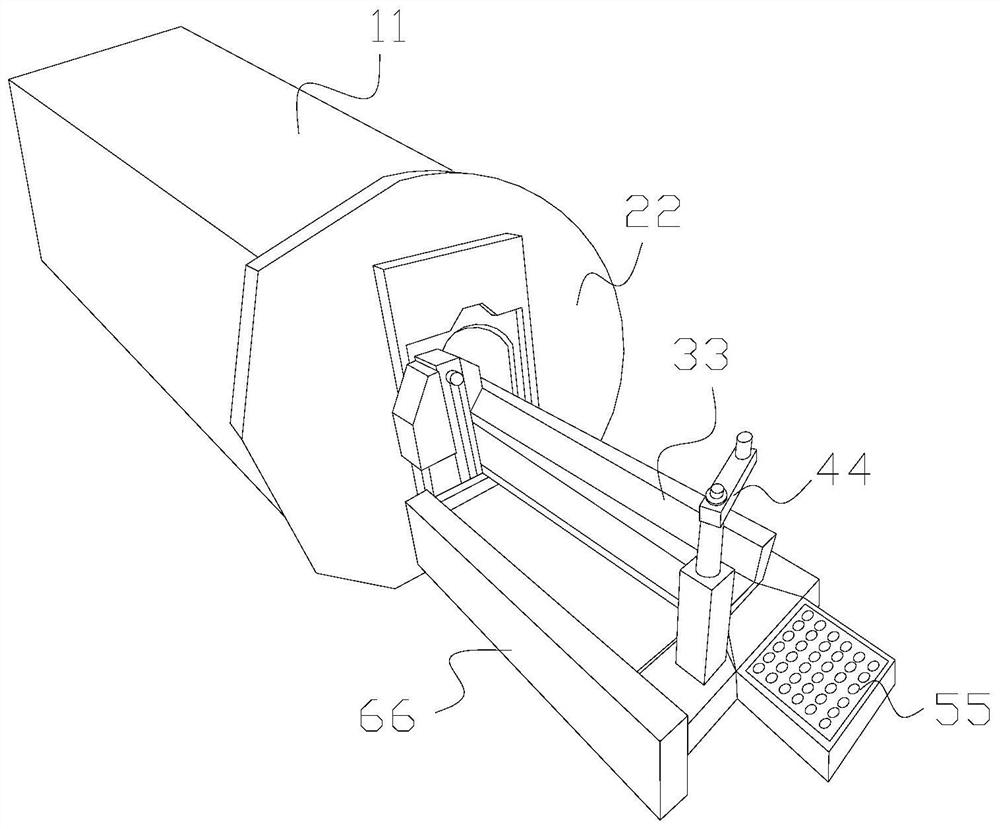

[0029] The present invention provides an anti-scratching semiconductor waffle tip opening section processing apparatus comprising a control tank 11, a partition plate 22, a pocket 33, an operation head 44, a bump cartridge 55, a bottom box 66.

[0030] The control box 11 is coupled to the partition plate 22, and the pocket 33 is embedded inside the compartment 22, the opener 44 is connected to the bottom pocket box 66, and the concave tank 55 welded to the bottom pocket. The outer surface of the box 66 is mounted on one end of the spacer plate 22 away from the control tank 11.

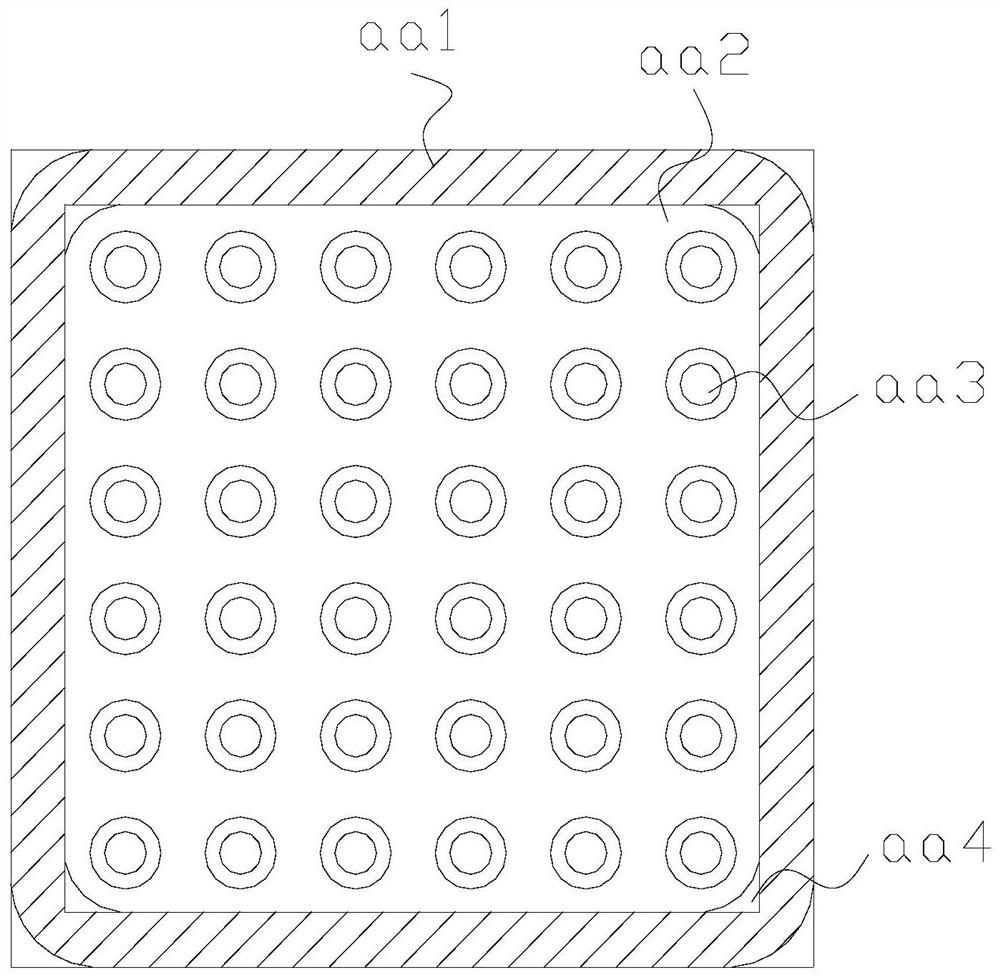

[0031] The concave convex cartridge 55 includes an outer housing AA1, an inner space AA2, a concave rod AA3, a corner, and the inner space AA2 is embedded inside the outer gear case AA1, and the concave rod AA3 is located inside the inner space AA2. The angle protection strip AA4 is bonded to the inner wall of the outer pocket AA1.

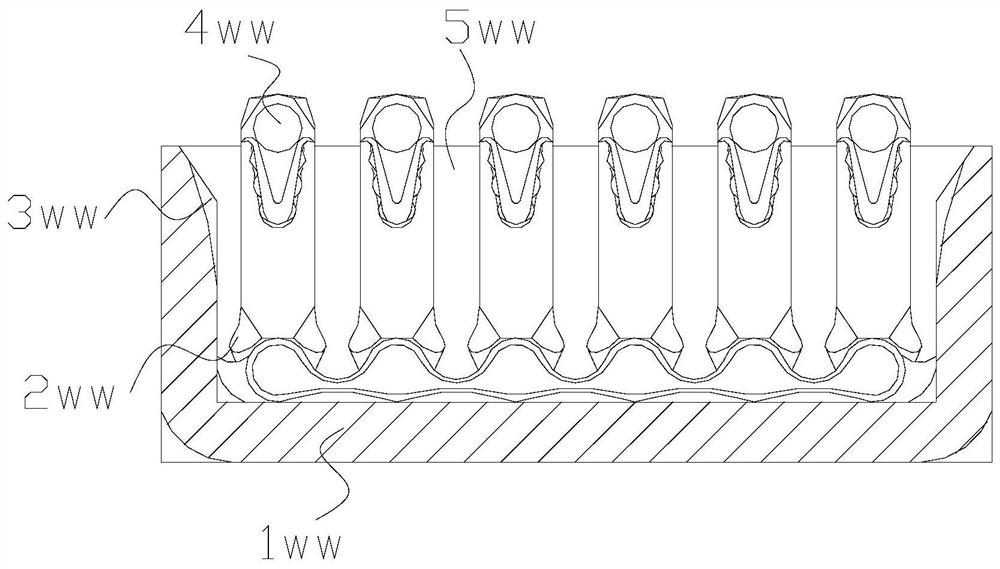

[0032] Wherein, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap