Dedusting mechanism of internal mixer

An internal mixer and machine room technology, which is applied in the direction of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as affecting product quality and dirty machine room, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

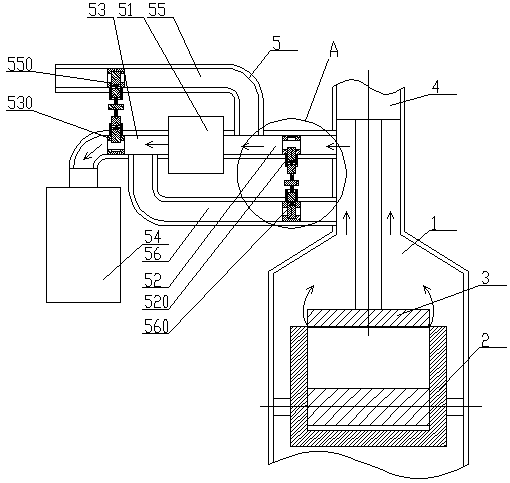

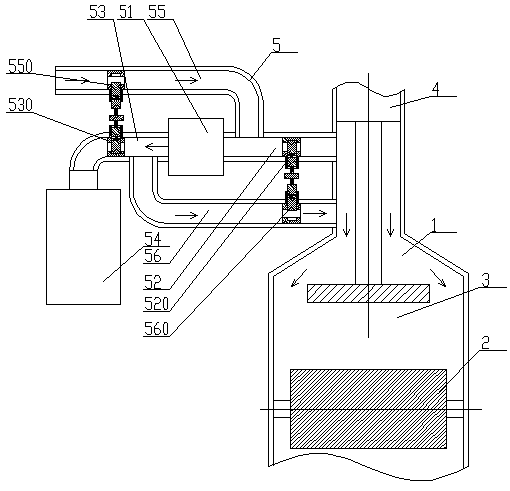

[0024] The present invention as Figure 1-3 As shown, the internal mixer includes a machine bin 1, a processing bin 2, a bin cover 3 and a lift drive assembly 4, the lower part of the processing bin is hinged at the bottom of the inner wall of the machine bin, and the lift drive assembly is connected to the machine bin The top of the inner wall, the cover is fixedly connected to the bottom end of the lifting drive assembly and is located above the processing warehouse, and the cover performs linear lifting movement under the action of the lifting drive assembly;

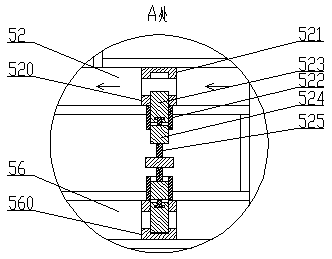

[0025] The dust removal mechanism 5 includes a fan 51, a negative pressure air inlet pipe 52, a negative pressure air outlet pipe 53, a dust collection bag 54, a positive pressure air inlet pipe 55 and a positive pressure air outlet pipe 56;

[0026] The negative pressure inlet pipe 52 is fixedly connected to the top of the outer wall of the machine room 1 and communicates with the inside of the machine room 1. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com